अगस्त . 17, 2025 03:20 Back to list

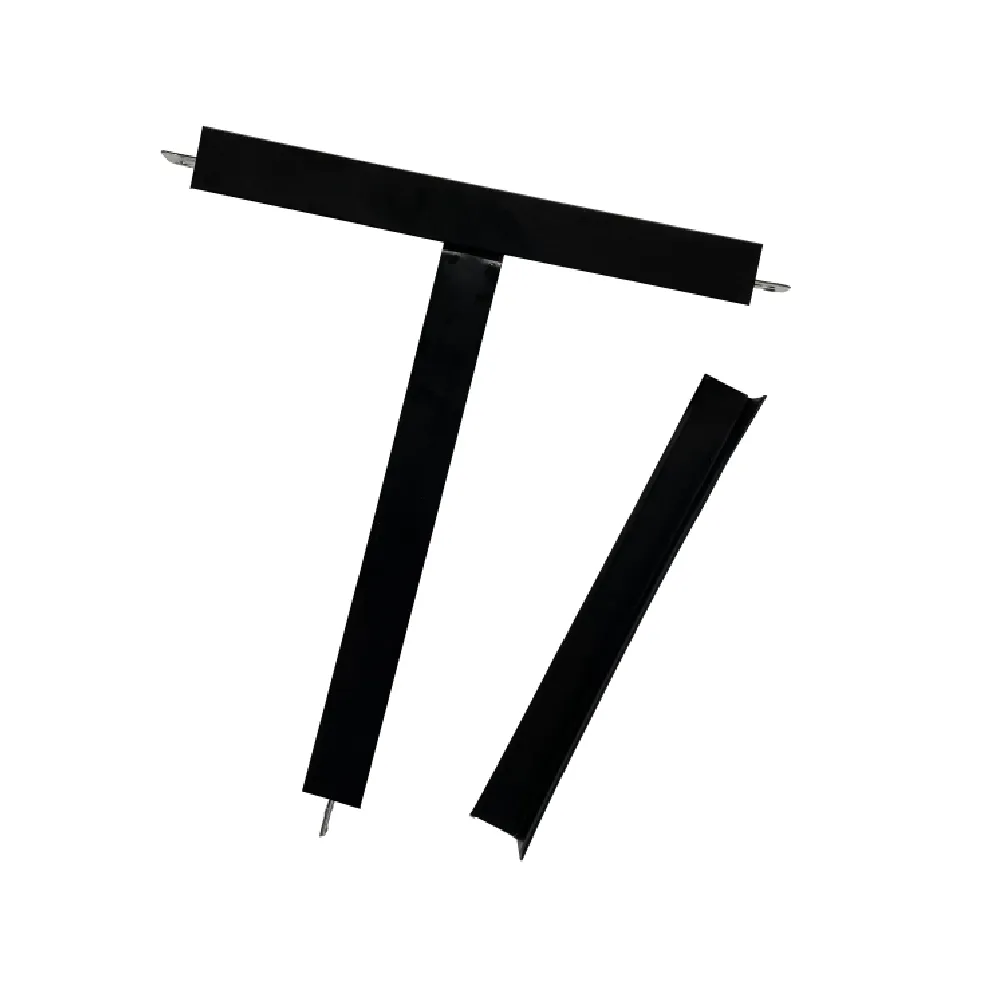

Durable Ceiling T Grid Systems for Easy Installation

The Pivotal Role of Suspension Systems in Modern Building Aesthetics and Functionality

In contemporary commercial and institutional architecture, the underlying infrastructure of ceiling systems is as crucial as the visible aesthetics. The ceiling t grid system stands as a fundamental component, offering a robust and versatile framework for suspended ceilings. This system is not merely about holding tiles; it’s about providing accessible plenum space for HVAC, lighting, and fire suppression systems, while ensuring structural integrity and contributing to acoustic and thermal performance. The global market for ceiling grids continues to expand, driven by increasing commercial construction, renovation projects, and a growing emphasis on energy efficiency and indoor air quality. Industry trends indicate a strong move towards integrated building solutions, where ceiling components like the t-grid are designed for seamless integration with intelligent building management systems, enhancing overall operational efficiency and occupant comfort. Understanding the nuances of grid ceiling material, from traditional steel to more advanced composites, is essential for architects and contractors striving for optimal performance and longevity in their projects. This detailed exposition delves into the engineering excellence and practical applications that position the suspended ceiling t-grid as an indispensable element in modern construction.

Decoding the Manufacturing Excellence of Ceiling T-Grids

The manufacturing of a high-quality ceiling t grid involves a precise, multi-stage process designed to ensure durability, structural integrity, and ease of installation. Primarily, these grids are fabricated from hot-dipped galvanized steel, which provides exceptional corrosion resistance, a critical factor for longevity in various environmental conditions. The process typically begins with large coils of steel, which undergo precision slitting to achieve the exact width required for the main runner and cross tee components. This is followed by a sophisticated roll-forming process, where the flat steel strips are progressively shaped into the characteristic ‘T’ profile, or specialized profiles for cross tee ceiling systems, using a series of rollers. Integrated into this automated line are punching and notching stations that create the precise cutouts and slots necessary for interlock mechanisms and suspension points. For enhanced fire resistance, some grids incorporate a double web design or specific coatings. Quality control is paramount throughout, adhering to stringent international standards such as ASTM C635 (Standard Specification for Manufacture, Performance, and Testing of Metal Suspension Systems for Acoustical Tile and Lay-in Panel Ceilings) and ISO 9001 for quality management systems. Each batch undergoes rigorous testing for load-bearing capacity, torsion strength, and dimensional accuracy. The typical lifespan of a properly installed and maintained t-grid system can exceed 50 years, making it a highly sustainable choice. While traditionally associated with commercial and office spaces, these grids find application in diverse sectors including healthcare, education, retail, and light industrial facilities, providing crucial access to utilities in the plenum space and contributing to superior acoustics and fire safety.

Technical Specifications and Performance Metrics

Selecting the appropriate ceiling t grid requires a comprehensive understanding of its technical specifications and performance characteristics, which directly impact a project's long-term viability and safety. Key parameters include the grid's dimensions, typically available in imperial (e.g., 2'x2', 2'x4') and metric (e.g., 600x600mm, 600x1200mm) configurations to accommodate various tile sizes. Load-bearing capacity is paramount, specified in pounds per linear foot (PLF) or kilograms per meter (kg/m), ensuring the grid can safely support ceiling tiles, light fixtures, diffusers, and other suspended elements without deflection. Corrosion resistance, often measured by salt spray testing (e.g., ASTM B117), determines the grid's suitability for humid or chemically aggressive environments. Fire rating, a critical safety specification, is typically assessed under standards like ASTM E119, classifying systems as 1-hour or 2-hour fire-rated assemblies, crucial for occupant safety and building code compliance. Acoustic performance, though primarily a function of the ceiling tile, is supported by a rigid grid structure that minimizes vibration transmission. When comparing the drywall ceiling grid price against a traditional t-grid system, the latter often offers greater flexibility for future access and utility integration, despite potential initial material cost variations. The long-term cost-effectiveness and ease of maintenance often favor a well-engineered t-grid system, especially when considering the lifecycle of components like gridstone ceiling tile cost.

| Parameter | Description | Typical Range/Value | Relevant Standard |

|---|---|---|---|

| Material | Hot-dipped Galvanized Steel | G30/G60 Galvanization | ASTM A653 |

| Grid Face Width | Visible width of the grid profile | 15mm, 24mm (0.6", 0.94") | ASTM C635 |

| Length Tolerance | Permissible deviation in length | ±0.5mm | ASTM C635 |

| Load-bearing Capacity | Maximum weight grid can support per linear foot/meter | 0.2-0.5 KN/m or 5-12 PLF | ASTM C635 |

| Fire Rating | Ability to withstand fire exposure | 1-hour, 2-hour (rated assembly) | ASTM E119, UL Classified |

| Corrosion Resistance | Resistance to rust and degradation | 96-1000+ hours salt spray | ASTM B117 |

Versatile Applications and Strategic Deployment

The adaptability of the ceiling t grid system allows for its strategic deployment across a vast spectrum of commercial and institutional environments, each leveraging its unique advantages. In corporate offices, the grid system facilitates rapid installation and future reconfigurations, enabling easy access to the plenum for maintenance of data cabling, electrical conduits, and HVAC systems. This accessibility significantly reduces downtime and operational costs over the building's lifecycle. For healthcare facilities, stringent requirements for hygiene and air quality make washable, demountable ceiling tiles, supported by corrosion-resistant grids, ideal. The ability to quickly replace damaged tiles or access concealed systems without extensive demolition is invaluable in hospitals and clinics. Educational institutions benefit from the system's robust design, accommodating heavy-duty lighting and sound systems while offering acoustic solutions that enhance learning environments. Retail spaces often prioritize aesthetic flexibility, and modern t-grid systems offer various face widths and colors, allowing for diverse design possibilities while simplifying the integration of display lighting and security cameras. Furthermore, in light industrial and manufacturing settings, the grid's capacity to support heavier loads and withstand harsher conditions, especially when specified with enhanced galvanization, proves indispensable. The inherent flexibility of the t-grid system also extends to its seismic performance, with specific clips and bracing options available to ensure structural integrity in earthquake-prone regions, making it a globally applicable solution.

Ensuring Quality and Reliability: Certifications and Trust

Building long-term partnerships in the B2B space hinges on reliability and unwavering support. For Ceilings t grid Suspended Systems, this commitment to quality is underscored by comprehensive certifications and rigorous testing. Our manufacturing processes are ISO 9001:2015 certified, affirming our dedication to consistent quality management and continuous improvement. This ensures that every ceiling t grid component meets or exceeds international standards for performance and durability. Furthermore, our products often carry CE marking, signifying compliance with European health, safety, and environmental protection standards, facilitating smooth project execution across diverse geographies. We maintain long-standing partnerships with leading architects, contractors, and material suppliers, testament to our reputation for delivering reliable solutions. With over 15 years of dedicated service in the ceiling suspension industry, our experience is reflected in the robustness of our products and the efficiency of our service delivery. Test data, including deflection tests, fire resistance ratings (e.g., in accordance with ASTM E119), and corrosion resistance reports (ASTM B117 salt spray tests), are readily available to demonstrate the superior performance of our grids under various conditions. These detailed analyses provide transparent insights into material properties and structural integrity, allowing specifiers to make informed decisions with confidence. Our commitment to authority is not just about certifications; it's about a consistent, verifiable track record of excellence in manufacturing and customer satisfaction.

Tailored Solutions and Project Case Studies

Recognizing that no two projects are identical, we specialize in providing customized ceiling t grid solutions that perfectly align with unique architectural visions and functional requirements. Beyond standard dimensions, we offer grids in various finishes, including white, black, and custom RAL colors, to integrate seamlessly with interior designs. Our technical team collaborates closely with clients from the conceptual phase to provide engineering support, including load calculations for heavy-duty applications or seismic bracing designs for critical infrastructures. This collaborative approach ensures that the chosen grid ceiling material and configuration optimize both performance and aesthetics. For instance, in a recent high-profile corporate campus project, our bespoke grid system allowed for the precise integration of custom-sized acoustic panels and sophisticated linear lighting, achieving a sleek, minimalist aesthetic while ensuring optimal sound control and illumination. Another notable case involved a large-scale hospital renovation where our rapid-installation t-grid system significantly reduced construction time, minimizing disruption to essential medical services while providing future-proof access to ceiling utilities. Client feedback consistently highlights our responsiveness, technical expertise, and ability to deliver on complex specifications within tight deadlines. These successful applications underscore our commitment to not just supplying products, but delivering comprehensive, tailored ceiling solutions that stand the test of time and performance expectations.

Partnering for Success: Trust and Support

Building long-term partnerships in the B2B space hinges on reliability and unwavering support. We understand the critical nature of project timelines and budget constraints, which is why our customer support is designed for efficiency and transparency. From initial inquiry to post-installation, our dedicated team provides comprehensive assistance. Our typical delivery cycles for standard ceiling t grid systems range from 2-4 weeks, depending on order volume and customization requirements, with expedited options available for urgent projects. We maintain robust inventory levels and a streamlined logistics network to ensure timely dispatch and delivery. To further enhance client confidence, all our Ceilings t grid Suspended Systems come with a comprehensive warranty against manufacturing defects, typically ranging from 10 to 15 years, reflecting our confidence in product durability. Should any issues arise, our responsive technical support team is available to provide troubleshooting, replacement guidance, and on-site assistance if necessary. We also offer detailed installation guides and technical specifications to ensure proper setup and optimal performance. Our commitment to client success extends beyond the sale; it's about providing ongoing support and being a trusted resource for all ceiling suspension needs.

Frequently Asked Questions (FAQ)

-

Q: What is the primary material used for your ceiling t-grids?

A: Our t-grids are primarily manufactured from high-quality hot-dipped galvanized steel, ensuring superior corrosion resistance and longevity.

-

Q: Are your ceiling t-grids compatible with all types of ceiling tiles?

A: Our standard ceiling t grid systems are designed to be compatible with most standard acoustic and mineral fiber ceiling tiles, typically in 2'x2', 2'x4', 600x600mm, and 600x1200mm sizes. We also offer specialized grids for unique tile dimensions.

-

Q: What is the fire rating of your t-grid systems?

A: Our t-grid systems can be specified to meet 1-hour or 2-hour fire resistance ratings as part of a complete fire-rated ceiling assembly, in accordance with ASTM E119 and other relevant standards.

-

Q: Do you offer custom color options for the ceiling t-grids?

A: Yes, in addition to standard white and black, we offer custom RAL color matching for our t-grids to meet specific aesthetic requirements for your project.

-

Q: How does your product support seismic performance requirements?

A: We provide specialized seismic bracing components and engineering guidance to ensure our ceiling t grid systems comply with stringent seismic design requirements, enhancing safety in earthquake-prone areas.

References

- American Society for Testing and Materials. (2020). ASTM C635/C635M - Standard Specification for Manufacture, Performance, and Testing of Metal Suspension Systems for Acoustical Tile and Lay-in Panel Ceilings.

- American Society for Testing and Materials. (2020). ASTM E119 - Standard Test Methods for Fire Tests of Building Construction and Materials.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems — Requirements.

-

PVC Gypsum Ceiling: Durable, Laminated Tiles for Modern SpacesNewsAug.28,2025

-

Pvc Gypsum Ceiling Is DurableNewsAug.21,2025

-

Mineral Fiber Board Is DurableNewsAug.21,2025

-

Ceiling Tile Clip Reusable DesignNewsAug.21,2025

-

Ceiling T Grid Modular DesignNewsAug.21,2025

-

Ceiling Hatch Key Mandatory ToolNewsAug.21,2025