Aug . 14, 2025 03:20 Back to list

PVC Gypsum Ceiling Tiles & Boards: Durable & Affordable

Understanding PVC Gypsum Ceilings: An In-Depth Look for B2B Professionals

In modern construction, the choice of interior finishes significantly impacts both aesthetic appeal and functional performance. PVC gypsum ceiling solutions have emerged as a premier choice for a wide array of commercial, industrial, and residential projects. These innovative ceiling panels offer a compelling blend of durability, hygiene, and design versatility, making them ideal for environments ranging from healthcare facilities and educational institutions to retail spaces and corporate offices. Their increasing adoption reflects a global trend towards materials that not only meet stringent performance criteria but also support rapid installation and long-term cost-effectiveness. The unique composition of a gypsum core laminated with a durable PVC film provides superior resistance to moisture, fire, and mildew, which are critical considerations in diverse building applications. This introductory overview sets the stage for a comprehensive exploration of their technical specifications, manufacturing intricacies, and diverse application potential.

The demand for advanced ceiling solutions is continuously evolving, driven by stricter building codes, greater emphasis on indoor air quality, and the need for adaptable interior designs. Modern building projects, particularly in the B2B sector, require materials that offer a balance of aesthetic flexibility and robust performance. This has propelled pvc gypsum ceiling tiles to the forefront of architectural specifications. Their ability to deliver a clean, durable, and visually appealing finish while providing practical benefits such as easy maintenance and enhanced acoustics makes them invaluable. As we delve deeper, we will explore the specific advantages these ceilings offer, from their technical parameters to their real-world application, providing valuable insights for procurement managers, architects, and construction professionals.

Industry Trends and Market Dynamics for PVC Gypsum Ceilings

The global market for pvc gypsum ceiling products is experiencing robust growth, propelled by the booming construction sector, especially in developing economies. According to recent market analyses, the global gypsum board market, including laminated varieties, is projected to reach approximately $40 billion by 2027, growing at a CAGR of around 5-6%. Key drivers include rapid urbanization, increasing investments in commercial infrastructure, and a heightened focus on sustainable and energy-efficient building practices. The preference for pvc laminated gypsum ceiling tiles is particularly strong in humid climates and areas requiring high hygiene standards, such as hospitals and food processing units, due to their superior moisture and mildew resistance. Furthermore, the aesthetic versatility of PVC laminates, available in a vast array of patterns and colors, aligns perfectly with contemporary interior design trends that prioritize both functionality and visual appeal.

Innovations in manufacturing processes are also contributing to market expansion. Manufacturers are increasingly adopting advanced lamination techniques that enhance the bond between the PVC film and the gypsum board, leading to improved durability and longevity of pvc laminated gypsum ceiling board products. There's a growing trend towards incorporating recycled content in gypsum core production and using eco-friendly PVC films, addressing the industry's shift towards green building materials. The competitive landscape is characterized by companies focusing on product differentiation through advanced features like enhanced acoustic performance, superior fire resistance, and bespoke design options. This dynamic environment necessitates that B2B buyers stay informed about the latest product developments and market shifts to make informed procurement decisions that align with project specifications and sustainability goals.

Technical Parameters and Specifications of PVC Gypsum Ceiling Tiles

Understanding the technical parameters of pvc laminated gypsum ceiling tiles is crucial for ensuring optimal performance and compliance with project requirements. These parameters directly influence the suitability of the ceiling for specific environments and applications. Key specifications typically include dimensions, thickness, weight, fire rating, thermal conductivity, sound absorption coefficient, and moisture resistance. Standard dimensions often include 595x595mm, 600x600mm, 603x603mm, and 600x1200mm, tailored to fit common ceiling grid systems. Thickness can range from 7mm to 12mm, with thicker panels offering enhanced rigidity and performance in areas requiring higher impact resistance or specific acoustic properties.

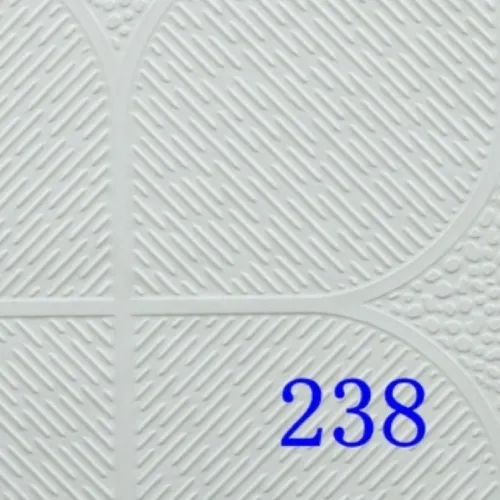

Figure 1: High-quality pvc gypsum ceiling panels ensuring aesthetic and functional excellence.

Below is a typical specification table outlining critical parameters for high-grade pvc laminated gypsum board price considerations:

| Parameter | Typical Specification (Xingyuan Quality) | Testing Standard |

|---|---|---|

| Material Composition | High-grade Gypsum Core, PVC Film Lamination, Aluminum Foil Backing | ASTM C1396, GB/T 9775 |

| Dimensions (mm) | 595x595, 600x600, 603x603, 600x1200 (Customizable) | EN 520, ISO 13958 |

| Thickness (mm) | 7.0mm, 7.5mm, 8.0mm, 9.0mm, 9.5mm, 10.0mm, 12.0mm | EN 520 |

| Weight (kg/sqm) | 5.5 - 9.5 (depending on thickness) | Internal QA |

| Fire Resistance | Class A (Non-combustible gypsum core) | ASTM E84, GB 8624 |

| Moisture Resistance | <5% moisture absorption rate (relative humidity 90%) | ASTM C1396, GB/T 9775 |

| Thermal Conductivity | 0.16 W/(m·K) | ISO 8301 |

| Sound Reduction Coefficient (NRC) | 0.3 - 0.5 (depending on panel structure) | ASTM C423 |

| Surface Treatment | PVC Laminated (various patterns), UV Coated for durability | Visual Inspection |

| Recycled Content | Up to 20% post-industrial gypsum | Internal Tracking |

These detailed specifications ensure that PVC gypsum ceiling panels deliver consistent and reliable performance across various challenging environments. The fire resistance, in particular, is a critical safety feature, as the gypsum core inherently contains chemically combined water which acts as a barrier to heat transfer, delaying flame spread. Paired with the protective PVC film, these panels offer an optimal solution for demanding commercial and public spaces, providing long-term structural integrity and peace of mind.

Comprehensive Manufacturing Process of PVC Gypsum Ceilings

The production of high-quality pvc gypsum ceiling tiles involves a meticulously controlled multi-stage manufacturing process, ensuring both dimensional accuracy and superior functional properties. It begins with the precise formulation of the gypsum slurry, typically comprising calcined gypsum plaster, water, and various additives such as starch, foam, and fiberglass reinforcing agents. This mixture is continuously poured onto a moving paper liner, forming the core of the gypsum board. A second paper liner is then applied on top, and the board undergoes an initial setting phase where the gypsum rapidly crystallizes and hardens.

Figure 2: Precision lamination of PVC film onto gypsum board for superior finish, crucial for pvc laminated gypsum ceiling tiles.

Following the initial setting, the continuous gypsum board is cut into specific lengths and conveyed through a multi-zone drying kiln. This critical step removes excess moisture, achieving optimal strength and dimensional stability. After drying, the raw gypsum boards are precisely cut into ceiling tile dimensions. The next crucial phase is the lamination process. A high-quality PVC film, pre-printed with desired patterns or colors, is adhesively bonded to the front face of the gypsum board using advanced lamination machinery. Simultaneously, an aluminum foil backing is often applied to the reverse side to enhance moisture resistance, thermal insulation, and fire retardancy. Each panel then undergoes rigorous quality control checks, including visual inspection for surface defects, dimensional verification, and sample testing for adhesion strength and material integrity. This detailed process ensures that every pvc laminated gypsum ceiling tiles unit meets stringent international standards such as ISO 9001 for quality management and relevant ASTM/EN standards for performance. The service life of these panels, when properly installed and maintained, can extend beyond 15-20 years, underscoring their exceptional durability.

Key Technical Advantages and Performance Benefits

The adoption of pvc gypsum ceiling solutions offers a multitude of technical advantages that are highly beneficial for commercial and industrial applications. Foremost among these is their inherent moisture resistance, provided by the PVC lamination and often augmented by an aluminum foil backing. This makes them exceptionally suitable for high-humidity environments such as bathrooms, kitchens, laboratories, and areas prone to condensation, preventing mold and mildew growth which can compromise indoor air quality and structural integrity. Furthermore, the gypsum core offers excellent fire retardant properties; upon exposure to high temperatures, the chemically combined water within the gypsum is released as steam, effectively cooling the surface and inhibiting fire spread, significantly enhancing occupant safety.

Figure 3: A diverse range of pvc gypsum ceiling textures and patterns for bespoke designs.

Beyond safety, these ceilings provide superior aesthetic flexibility. The PVC surface can replicate various textures, from wood grains to metallic finishes, allowing for highly customized interior designs without the cost or maintenance associated with natural materials. They are also remarkably easy to clean and maintain, requiring only a simple wipe-down with a damp cloth, which is a significant advantage in hygiene-sensitive environments. From an installation perspective, the lightweight nature of pvc laminated gypsum board facilitates quick and efficient installation within standard suspended ceiling grid systems, reducing labor costs and project timelines. Their dimensional stability ensures they do not warp or sag over time, maintaining a pristine appearance for years. These combined attributes contribute to a lower total cost of ownership over the product's lifespan, making them a wise investment for long-term building projects.

Application Scenarios and Industry Suitability

The versatility and robust performance characteristics of pvc gypsum ceiling tiles make them suitable for an extensive range of application scenarios across various industries. In the commercial sector, they are extensively used in office buildings, retail stores, and shopping malls, where their clean appearance, ease of maintenance, and fire resistance are highly valued. Their ability to integrate seamlessly with lighting and HVAC systems within a suspended grid also contributes to their popularity in these dynamic environments. For healthcare facilities, including hospitals, clinics, and laboratories, the hygienic surface and moisture resistance of PVC gypsum ceilings are paramount, preventing the accumulation of bacteria and ensuring easy sanitization, which is critical for patient safety and infection control.

Educational institutions, from schools to universities, also benefit from the durability and sound-absorbing properties of pvc laminated gypsum ceiling board. Improved acoustics can enhance learning environments by reducing echo and noise, while the easy-to-clean surface withstands the rigors of high-traffic areas. Furthermore, in industrial settings such as light manufacturing facilities or cleanrooms, where dust control and ease of cleaning are crucial, these ceilings provide an ideal solution. Even in high-end residential projects, especially for basements, bathrooms, and utility rooms, their moisture and mold resistance offers significant advantages. Their adaptability, combined with their aesthetic appeal and functional benefits, positions them as a leading choice for architects and contractors seeking reliable and visually appealing ceiling solutions across diverse sectors.

Manufacturer Comparison and Choosing the Right Partner

Selecting the right manufacturer for pvc gypsum ceiling products is crucial for project success, impacting quality, reliability, and long-term performance. While many suppliers exist, key differentiators include adherence to international quality standards, manufacturing precision, customization capabilities, and post-sales support. A reputable manufacturer, like Xingyuan Ceilings, distinguishes itself through a proven track record of delivering consistently high-quality products that meet rigorous performance benchmarks. Our commitment to innovation ensures that our pvc laminated gypsum ceiling tiles not only comply with current industry standards but also anticipate future market demands, offering superior fire resistance, moisture protection, and acoustic properties.

| Feature/Aspect | Xingyuan Ceilings (Premium Supplier) | Standard Supplier (Typical) |

|---|---|---|

| Gypsum Core Quality | High-density, low-sulfur content, reinforced with fiberglass | Standard density, variable composition |

| PVC Film Thickness & Durability | 0.07mm - 0.10mm, UV-stabilized, anti-scratch | 0.05mm - 0.06mm, basic durability |

| Adhesion Strength | Superior, industrial-grade adhesive, no delamination | Varies, potential for delamination over time |

| Certifications | ISO 9001, CE, ASTM compliant, fire-rated | Basic or no international certifications |

| Customization Options | Extensive patterns, colors, sizes, and custom printing | Limited standard designs and sizes |

| Warranty & Support | Comprehensive warranty, dedicated technical support | Limited or no formal warranty |

| Lead Time & Delivery | Optimized production, reliable global logistics (Typically 2-4 weeks) | Variable, potential delays |

When assessing potential partners, consider their experience in the B2B sector, their capacity to handle large-scale orders, and their commitment to sustainable practices. A manufacturer like Xingyuan, with decades of specialized experience, offers not just a product but a comprehensive solution, including technical consultation and logistical support. This level of partnership is invaluable for ensuring that project timelines are met and that the final installation of pvc laminated gypsum board exceeds client expectations in terms of both aesthetics and long-term performance.

Customization Solutions and Bespoke PVC Gypsum Ceiling Designs

One of the significant advantages of pvc gypsum ceiling systems is their inherent flexibility for customization, allowing architects and designers to bring unique visions to life without compromising on performance. Manufacturers like Xingyuan offer extensive customization options beyond standard patterns and colors. This includes the ability to replicate specific textures, incorporate bespoke patterns or corporate logos through advanced digital printing on the PVC film, and even produce panels with unique dimensions to fit non-standard ceiling grid layouts. The versatility extends to functional enhancements, such as varying the core density for improved acoustic performance or integrating specific fire-resistant additives to meet stringent local building codes.

The customization process typically involves close collaboration between the client and the manufacturer's technical design team. This ensures that all specific project requirements, from aesthetic considerations to functional demands, are meticulously addressed during the production phase. Whether it's a large-scale commercial complex requiring a unified brand aesthetic across all ceilings or a specialized healthcare facility needing ultra-hygienic and durable surfaces, tailored pvc laminated gypsum ceiling tiles provide the ideal solution. This bespoke approach minimizes waste, optimizes material usage, and ultimately delivers a highly refined end product that seamlessly integrates with the overall architectural design, enhancing both visual appeal and operational efficiency.

Figure 4: Seamless integration of pvc gypsum ceiling panels in a modern commercial space.

Application Case Studies and Real-World Successes

The practical utility and superior performance of pvc gypsum ceiling panels are best illustrated through real-world application cases. For instance, a prominent hospital in Southeast Asia recently utilized these ceilings in their new wing. The stringent hygiene requirements, coupled with the need for moisture resistance in patient rooms and operating theaters, made PVC laminated gypsum the ideal choice. The easy-to-clean surface and antimicrobial properties of the PVC film significantly contributed to maintaining a sterile environment, while the inherent fire resistance of the gypsum core provided crucial safety features, surpassing local building codes. This project demonstrated the critical role of these ceilings in high-demand, sensitive environments.

Another notable application involved a large corporate office complex in Europe. Here, the emphasis was on creating aesthetically pleasing, acoustically optimized, and low-maintenance workspaces. The diverse range of patterns and colors available for pvc gypsum ceiling tiles allowed architects to achieve a modern and sophisticated aesthetic that aligned with the company's brand identity. Furthermore, the excellent sound absorption properties contributed to a quieter and more productive work environment, significantly reducing noise pollution from open-plan areas. The rapid installation process also ensured minimal disruption to business operations during the renovation, highlighting the efficiency and practical benefits these ceiling solutions offer in large-scale commercial projects.

Frequently Asked Questions (FAQ) about PVC Gypsum Ceilings

-

Q: What is the typical lead time for large orders of PVC Gypsum Ceiling panels?

A: For standard specifications and quantities, our typical production lead time is 2-4 weeks from order confirmation. For highly customized or exceptionally large orders, a more precise timeline will be provided upon project assessment. We maintain efficient supply chain management to ensure timely delivery. -

Q: Do your PVC Laminated Gypsum Boards come with a warranty?

A: Yes, all our pvc laminated gypsum board products come with a comprehensive manufacturer's warranty covering material defects and delamination under normal use and proper installation. The exact terms and duration are detailed in our product documentation. We stand behind the quality and durability of our ceilings. -

Q: Are PVC Gypsum Ceiling Tiles suitable for outdoor use or high-temperature environments?

A: While highly moisture-resistant, pvc gypsum ceiling panels are primarily designed for indoor applications and are not recommended for direct outdoor exposure or environments exceeding 60°C (140°F) for prolonged periods, as extreme UV exposure or heat can affect the PVC film. For specific environmental concerns, please consult our technical team. -

Q: How do PVC Gypsum Ceilings contribute to indoor air quality?

A: Our PVC Gypsum Ceiling products are designed to be low-VOC (Volatile Organic Compounds), ensuring minimal emissions and contributing to healthier indoor air quality. The PVC film also creates a smooth, non-porous surface that is easy to clean, reducing the accumulation of dust, allergens, and microbial growth, further enhancing the indoor environment.

For any further technical queries or specific project requirements, our dedicated customer support and technical advisory teams are available to provide detailed information and guidance. We are committed to ensuring our clients have all the necessary information to make informed decisions and achieve successful outcomes with our pvc gypsum ceiling solutions.

Conclusion: The Future of Interior Ceilings with PVC Gypsum Technology

The evolution of building materials has positioned pvc gypsum ceiling systems as a cornerstone for modern construction, offering an unparalleled combination of durability, aesthetic flexibility, and performance. From their rigorous manufacturing process ensuring consistent quality to their extensive array of technical advantages including fire resistance, moisture protection, and ease of maintenance, these ceilings meet the complex demands of today’s commercial and industrial environments. The capacity for customization further enhances their appeal, allowing for bespoke solutions that align precisely with architectural visions and functional needs. As the construction industry continues to prioritize efficiency, sustainability, and long-term value, PVC gypsum ceiling products represent a smart investment that delivers on all fronts, ensuring reliable and visually appealing overhead solutions for years to come.

References

- ASTM International. (2023). ASTM C1396/C1396M, Standard Specification for Gypsum Board.

- International Organization for Standardization. (2022). ISO 9001:2015, Quality management systems — Requirements.

- European Committee for Standardization. (2020). EN 520, Gypsum plasterboards — Definitions, requirements and test methods.

- Acoustical Society of America. (2021). ANSI/ASA S12.60, Acoustical Performance Criteria, Design Requirements, and Guidelines for Schools.