Dec . 12, 2024 09:39 Back to list

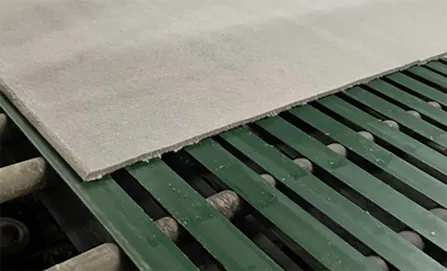

rigid mineral wool insulation sheets

Understanding Rigid Mineral Wool Insulation Sheets Benefits and Applications

Rigid mineral wool insulation sheets have gained significant popularity in the construction industry, thanks to their outstanding thermal performance, fire resistance, and versatility. This type of insulation is created from natural or recycled materials, including basalt rock and glass, making it not only efficient but also environmentally friendly. In this article, we will delve into the advantages, applications, and installation methods of rigid mineral wool insulation sheets.

Advantages of Rigid Mineral Wool Insulation

1. Thermal Efficiency One of the primary benefits of mineral wool insulation is its excellent thermal resistance, indicated by its High R-value. This efficiency helps maintain comfortable indoor temperatures by reducing heat loss in winter and keeping homes cool in summer. In energy-intensive buildings, this translates into significant savings on heating and cooling costs.

2. Fire Resistance Rigid mineral wool insulation is non-combustible and can withstand high temperatures, making it an ideal choice for fire-rated walls and roofs. The material does not emit toxic gases when exposed to fire, enhancing safety in residential and commercial buildings. Many building codes and regulations favor mineral wool as a fire-resistant solution.

3. Sound Insulation Beyond thermal insulation, mineral wool sheets provide excellent sound-absorbing qualities. They are widely used in commercial buildings, music studios, and residential homes to minimize noise transmission between spaces. This characteristic improves acoustic comfort, leading to a more pleasant living or working environment.

4. Moisture Resistance Mineral wool insulation has a unique structure that resists moisture absorption, helping to prevent mold and mildew growth. This moisture-resistant feature is crucial, especially in environments with high humidity levels or where condensation might occur.

5. Sustainable Option Many manufacturers produce rigid mineral wool insulation from recycled materials, aligning with the growing demand for sustainable building products. The longevity and durability of mineral wool also mean less waste over time, making it a more sustainable choice for building projects.

Applications of Rigid Mineral Wool Insulation

Rigid mineral wool insulation sheets can be used in various applications, from residential homes to large commercial structures. Some common uses include

1. Walls These insulation sheets are fitted between wall studs to provide a thermal and sound barrier, enhancing the energy efficiency and comfort of the building. They are particularly beneficial in multi-family homes and high-rise buildings where sound insulation is critical.

rigid mineral wool insulation sheets

2. Roofs Rigid mineral wool sheets are also employed as insulation in flat and pitched roofs. Their fire resistance and durability make them suitable for use in commercial roofing systems, helping to protect buildings from heat loss and gain.

3. Floors When installed under floorboards, mineral wool insulation can help keep homes warm while also reducing noise transmission between floors. This application is especially useful in multi-story buildings where sound transfer can be an issue.

4. Industrial Applications In industrial settings, rigid mineral wool insulation is used for thermal insulation of pipes, boilers, and equipment. Its high-temperature resistance is vital in facilities where heat retention is necessary for operational efficiency.

Installation of Rigid Mineral Wool Insulation

Installing rigid mineral wool insulation sheets requires careful planning to maximize their benefits. Here are some general guidelines

1. Measure and Cut Begin by measuring the area to be insulated. Cut the mineral wool sheets to size using a sharp utility knife, ensuring they fit snugly between wall studs or joists.

2. Seal and Secure Use appropriate sealants and fasteners to secure the sheets in place. It’s crucial to avoid gaps and air leaks to enhance the insulation's effectiveness.

3. Vapor Barrier In areas with high humidity, consider installing a vapor barrier over the insulation to prevent moisture buildup.

4. Safety Precautions Always follow safety guidelines when handling mineral wool, such as wearing gloves and a mask, as inhaling dust can cause irritation.

Conclusion

Rigid mineral wool insulation sheets are a robust solution for enhancing energy efficiency, fire safety, and sound control in buildings. Their versatility and environmentally friendly characteristics make them a top choice for modern construction projects. Whether you are building a new home or renovating an existing structure, incorporating rigid mineral wool insulation can significantly improve the overall performance and comfort of your space.

-

Quality Ceiling Trap Doors & Access Panels | Easy & Secure AccessNewsAug.30,2025

-

Durable Ceiling T Grid Systems | Easy InstallationNewsAug.29,2025

-

PVC Gypsum Ceiling: Durable, Laminated Tiles for Modern SpacesNewsAug.28,2025

-

Pvc Gypsum Ceiling Is DurableNewsAug.21,2025

-

Mineral Fiber Board Is DurableNewsAug.21,2025

-

Ceiling Tile Clip Reusable DesignNewsAug.21,2025