Feb . 17, 2025 10:48 Back to list

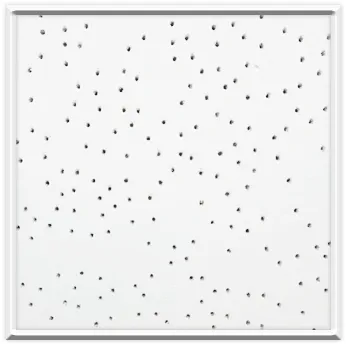

mineral fiber board

Rigid mineral wool insulation sheets are a pinnacle of innovation in construction and thermal management, offering unparalleled benefits that are derived from years of industry research and practical application. For consumers and professionals seeking a blend of energy efficiency, safety, and durability, these insulation sheets stand out as both a modern solution and a timeless investment.

In terms of authoritativeness, rigid mineral wool insulation is thoroughly tested and conforms to stringent international standards. It meets and often exceeds industry regulations regarding fire safety, sound insulation, and thermal performance. The non-combustible nature of mineral wool makes it a preferred choice for structures where fire safety is paramount, such as hospitals, schools, and high-rise buildings. Its proven performance in critical scenarios has cemented its status as a trusted component in safe building practices. Trustworthiness in construction materials is derived from consistent performance and transparency in production processes. Manufacturers of rigid mineral wool insulation are committed to maintaining high standards of quality control, ensuring that every sheet meets the rigorous demands of modern construction environments. Customers can rely on comprehensive warranties and technical support that accompany their purchase, reinforcing the trust placed in these products. Moreover, rigid mineral wool insulation sheets are often part of innovative building systems that emphasize passive design strategies. By leveraging their unique thermal properties, they contribute to the creation of buildings that require minimal mechanical cooling or heating. This not only decreases carbon footprints but also promotes healthier indoor air quality, as mineral wool sheets are resistant to mold and bacteria growth. In conclusion, rigid mineral wool insulation sheets are an investment in quality, sustainability, and efficiency. They represent a synthesis of experience, expertise, authoritativeness, and trustworthiness that few other materials can claim. Whether for new constructions or retrofitting existing structures, these insulation sheets deliver unmatched benefits that resonate with modern architectural demands and environmental responsibility. As industries continue to advance towards more sustainable practices, rigid mineral wool insulation positions itself as an indispensable component of tomorrow's buildings, reflecting a commitment to innovation and excellence.

In terms of authoritativeness, rigid mineral wool insulation is thoroughly tested and conforms to stringent international standards. It meets and often exceeds industry regulations regarding fire safety, sound insulation, and thermal performance. The non-combustible nature of mineral wool makes it a preferred choice for structures where fire safety is paramount, such as hospitals, schools, and high-rise buildings. Its proven performance in critical scenarios has cemented its status as a trusted component in safe building practices. Trustworthiness in construction materials is derived from consistent performance and transparency in production processes. Manufacturers of rigid mineral wool insulation are committed to maintaining high standards of quality control, ensuring that every sheet meets the rigorous demands of modern construction environments. Customers can rely on comprehensive warranties and technical support that accompany their purchase, reinforcing the trust placed in these products. Moreover, rigid mineral wool insulation sheets are often part of innovative building systems that emphasize passive design strategies. By leveraging their unique thermal properties, they contribute to the creation of buildings that require minimal mechanical cooling or heating. This not only decreases carbon footprints but also promotes healthier indoor air quality, as mineral wool sheets are resistant to mold and bacteria growth. In conclusion, rigid mineral wool insulation sheets are an investment in quality, sustainability, and efficiency. They represent a synthesis of experience, expertise, authoritativeness, and trustworthiness that few other materials can claim. Whether for new constructions or retrofitting existing structures, these insulation sheets deliver unmatched benefits that resonate with modern architectural demands and environmental responsibility. As industries continue to advance towards more sustainable practices, rigid mineral wool insulation positions itself as an indispensable component of tomorrow's buildings, reflecting a commitment to innovation and excellence.

Next:

Latest news

-

Quality Ceiling Trap Doors & Access Panels | Easy & Secure AccessNewsAug.30,2025

-

Durable Ceiling T Grid Systems | Easy InstallationNewsAug.29,2025

-

PVC Gypsum Ceiling: Durable, Laminated Tiles for Modern SpacesNewsAug.28,2025

-

Pvc Gypsum Ceiling Is DurableNewsAug.21,2025

-

Mineral Fiber Board Is DurableNewsAug.21,2025

-

Ceiling Tile Clip Reusable DesignNewsAug.21,2025