Nov . 18, 2024 21:56 Back to list

what is mineral fiber board

Understanding Mineral Fiber Board A Comprehensive Overview

Mineral fiber board, often referred to as mineral fiber insulation board, is a building material widely recognized for its exceptional thermal and acoustic properties. Composed primarily of natural minerals and recycled materials, this product is engineered for various applications, particularly in construction and industrial settings. This article explores the characteristics, benefits, production methods, applications, and environmental impact of mineral fiber board.

Composition and Characteristics

Mineral fiber boards are made from a combination of natural minerals—primarily basalt, silica, and other inorganic materials. The manufacturing process involves melting these minerals at high temperatures to create fibers, which are then combined with binders to form boards. The resulting material is lightweight, non-combustible, and resistant to moisture, mold, and mildew.

One key feature of mineral fiber boards is their impressive thermal resistance, making them ideal for insulation purposes. These boards have a low thermal conductivity rating, which helps improve energy efficiency in buildings. Additionally, their sound-dampening properties make them suitable for use in both residential and commercial environments, where noise reduction is a concern.

Benefits of Mineral Fiber Board

1. Thermal Performance Mineral fiber boards provide excellent insulation, helping to regulate indoor temperatures and reduce energy consumption for heating and cooling.

2. Acoustic Properties These boards effectively absorb sound, making them a popular choice in spaces that require noise control, such as offices, schools, and theaters.

3. Fire Resistance Being composed of non-combustible materials, mineral fiber boards offer a high level of fire resistance, which contributes to overall building safety.

4. Moisture Resistance The boards are resistant to moisture absorption, minimizing the risk of mold and bacterial growth, which is crucial for maintaining indoor air quality.

5. Sustainability Many mineral fiber boards are produced with recycled materials, contributing to environmentally friendly building practices.

Production Methods

The manufacturing of mineral fiber boards typically involves several steps

1. Raw Material Preparation High-quality natural minerals and recycled materials are sourced and prepared for processing.

2. Melting The raw materials are melted in a furnace at temperatures exceeding 1,500 degrees Celsius.

what is mineral fiber board

3. Fiber Formation The molten material is extruded and spun to create fine fibers, which are collected in a mat form.

4. Bonding A binder is applied to the mat to hold the fibers together, ensuring structural integrity.

5. Curing The bonded mat is cured through heat or other methods to achieve the desired density and strength.

6. Cutting and Finishing The cured boards are cut to size and finished according to specific requirements, ready for distribution.

Applications

Mineral fiber boards are versatile and can be used in various applications, including

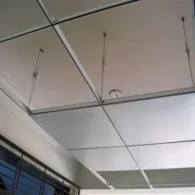

- Wall and Ceiling Insulation They are commonly used to insulate walls and ceilings in homes and commercial buildings, contributing to energy efficiency and comfort.

- Industrial Applications In industrial settings, mineral fiber boards serve as insulation for pipes, ducts, and equipment, protecting against heat loss and improving operational efficiency.

- Acoustic Panels In spaces where sound control is essential, such as concert halls, recording studios, and open office spaces, mineral fiber boards are utilized as acoustic panels to enhance sound quality.

- Fireproofing Due to their fire-resistant properties, these boards are used in fireproofing applications, providing safety and compliance with building codes.

Environmental Impact

The environmental benefits of mineral fiber boards can be significant. Many manufacturers focus on sustainability by incorporating recycled materials into their products and adhering to environmentally friendly production practices. Moreover, the energy efficiency achieved through proper insulation reduces the overall carbon footprint of buildings over their lifecycle.

Conclusion

In conclusion, mineral fiber board is a highly effective building material that provides numerous benefits in thermal insulation, soundproofing, and fire resistance. Its versatile applications and sustainable production processes make it an attractive choice for both builders and homeowners looking to enhance energy efficiency and safety in their projects. As we move towards more sustainable building practices, the role of mineral fiber boards in construction is likely to grow, making them an essential material in the future of the industry.

-

Durable Ceiling T Grid Systems | Easy InstallationNewsAug.29,2025

-

PVC Gypsum Ceiling: Durable, Laminated Tiles for Modern SpacesNewsAug.28,2025

-

Pvc Gypsum Ceiling Is DurableNewsAug.21,2025

-

Mineral Fiber Board Is DurableNewsAug.21,2025

-

Ceiling Tile Clip Reusable DesignNewsAug.21,2025

-

Ceiling T Grid Modular DesignNewsAug.21,2025