aug. . 27, 2025 04:40 Back to list

PVC Gypsum Ceiling Tiles: Durable, Laminated & Stylish Solutions

Introduction to PVC Gypsum Ceilings in B2B Applications

In contemporary commercial and industrial construction, the selection of appropriate ceiling materials is critical for both functional performance and aesthetic appeal. The pvc gypsum ceiling represents a technologically advanced solution, engineered to meet the stringent demands of modern B2B environments. This material, a composite of a gypsum core laminated with PVC film, offers a superior combination of durability, moisture resistance, hygiene, and design versatility compared to traditional alternatives.

Specifically, pvc gypsum ceiling tiles and pvc laminated gypsum ceiling board products have gained significant traction across various sectors, from healthcare and education to retail and corporate offices. Their specialized construction addresses common challenges such as humidity control, ease of maintenance, and compliance with strict hygiene standards. This comprehensive overview delves into the industry trends, technical specifications, application scenarios, and key advantages that position pvc gypsum ceiling solutions as a preferred choice for discerning architects, contractors, and facility managers.

Current Industry Trends and Market Dynamics

The global market for advanced ceiling systems is experiencing robust growth, driven by increasing construction activities, a heightened focus on energy efficiency, and evolving architectural demands for functional aesthetics. Key trends influencing the adoption of pvc gypsum ceiling products include:

- Sustainability and Green Building Initiatives: There is a growing demand for materials with lower environmental impact. Manufacturers are increasingly focusing on recyclable components and processes that reduce waste, aligning with certifications like LEED and BREEAM.

- Enhanced Performance Requirements: Modern buildings demand ceilings that offer superior acoustic performance, improved thermal insulation, and advanced fire resistance. Innovations in pvc laminated gypsum ceiling tiles are addressing these needs with specialized core formulations and lamination techniques.

- Hygiene and Cleanliness: Post-pandemic, the emphasis on sanitary environments in healthcare, food processing, and educational facilities has surged. The washable and non-porous surface of PVC laminated gypsum boards makes them ideal for maintaining high hygiene standards.

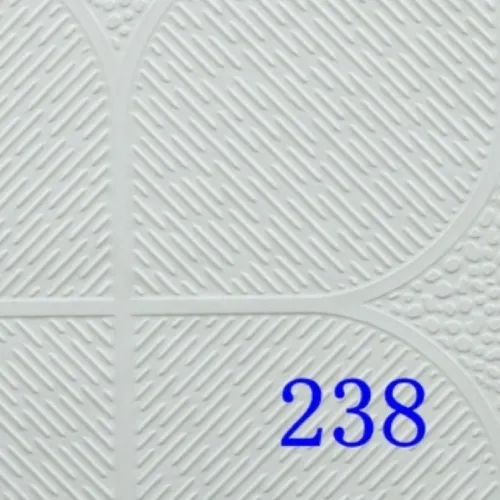

- Aesthetic Versatility: Architects and designers are seeking ceiling solutions that offer extensive customization options in terms of patterns, colors, and textures. The PVC lamination allows for a broad spectrum of visual effects, from subtle textures to high-gloss finishes, catering to diverse design palettes.

- Cost-Effectiveness and Ease of Installation: While initial pvc laminated gypsum board price might be a consideration, the long-term benefits of durability, low maintenance, and quick installation contribute to a favorable total cost of ownership for these systems.

These trends collectively underscore the increasing relevance and market expansion for sophisticated ceiling solutions like pvc gypsum ceiling products.

Manufacturing Process of PVC Gypsum Ceiling

The production of a pvc gypsum ceiling involves a meticulous process that combines the inherent properties of gypsum with the protective and aesthetic qualities of PVC film. This multi-stage manufacturing ensures a high-performance finished product.

Process Flow:

- Gypsum Board Production:

Raw Material Preparation:High-purity gypsum rock (calcium sulfate dihydrate) is crushed, calcined (dehydrated) to produce Plaster of Paris (calcium sulfate hemihydrate), and then mixed with water, paper pulp, starch, and various additives (e.g., foaming agents, accelerators) to form a slurry.Casting and Forming:The slurry is continuously cast between two sheets of specialized paper board. The gypsum quickly sets and hardens, forming a solid core.Drying:The wet boards are cut to length and passed through multi-stage dryers to remove excess moisture, ensuring dimensional stability and strength.

- PVC Lamination:

Surface Preparation:The dried gypsum boards are cleaned to ensure a dust-free surface for optimal adhesion.Adhesive Application:A high-performance adhesive, often water-based or solvent-free for environmental compliance, is applied evenly to the face of the gypsum board.PVC Film Application:A decorative and protective PVC film (polyvinyl chloride), pre-printed or textured, is precisely laminated onto the adhesive-coated gypsum board using a specialized laminating machine with controlled pressure and temperature. A foil backing (typically aluminum) can also be applied to the reverse side for enhanced thermal and moisture barrier properties.

- Cutting and Finishing:

Precision Cutting:The laminated boards are cut into standard sizes (e.g., 600x600mm, 600x1200mm) or custom dimensions using automated CNC cutting equipment, ensuring dimensional accuracy.Edge Sealing (Optional):Edges may be sealed or wrapped with PVC tape for enhanced moisture resistance and a cleaner finish, particularly for specific applications.Quality Control:Each batch undergoes rigorous testing for adhesion, dimensional stability, surface integrity, fire resistance, and moisture resistance, adhering to international standards like ISO 9001, ASTM E84, and EN 520.

- Packaging and Distribution:

Protective Packaging:Finished pvc gypsum ceiling tiles are carefully packaged in robust cartons or pallets to prevent damage during transit.

The typical service life for well-maintained pvc laminated gypsum ceiling tiles can exceed 15-20 years, depending on environmental conditions and usage. Target industries include healthcare (hospitals, clinics), education (schools, universities), commercial (offices, retail, hotels), food processing, cleanrooms, and other environments requiring high hygiene and durability.

Technical Specifications and Performance Parameters

The performance of pvc gypsum ceiling tiles is defined by a range of technical parameters, ensuring suitability for demanding commercial and industrial applications. Understanding these specifications is crucial for proper material selection and compliance.

Key Product Specifications:

These parameters collectively define the robust performance profile of pvc laminated gypsum ceiling board, making it a reliable choice for diverse B2B environments. Adherence to standards like ISO 9001 and CE marking further assures quality and compliance.

Application Scenarios and Target Industries

The versatility and performance characteristics of pvc gypsum ceiling solutions make them suitable for a wide array of commercial and industrial applications where durability, hygiene, and aesthetics are paramount.

Key Application Environments:

- Healthcare Facilities: Hospitals, clinics, laboratories, and pharmaceutical manufacturing plants benefit from the smooth, washable, and anti-microbial properties of pvc laminated gypsum ceiling tiles. They facilitate easy cleaning and support infection control protocols, making them ideal for sterile environments.

- Education Sector: Schools, universities, and daycare centers require durable, easy-to-maintain, and safe ceiling options. The robustness of pvc gypsum ceiling helps withstand wear and tear, while acoustic properties can improve learning environments.

- Commercial & Retail Spaces: Offices, shopping malls, supermarkets, and hotels utilize these ceilings for their aesthetic versatility, light reflectance, and cost-effectiveness over the product lifecycle. The wide range of finishes available for pvc laminated gypsum ceiling board supports diverse branding and interior design schemes.

- Food Processing & Kitchens: In areas requiring strict sanitation, such as commercial kitchens, cafeterias, and food production facilities, the moisture resistance and ease of cleaning of pvc gypsum ceiling boards are indispensable.

- Industrial & Manufacturing: Certain manufacturing environments, including cleanrooms or light industrial areas, benefit from the low particle emission and robust nature of these ceilings, ensuring compliance with operational standards.

- Water Supply & Drainage Facilities: Although less common for direct ceiling application, the principles of corrosion resistance and moisture protection inherent in PVC lamination can be extended to utility spaces within these facilities where humidity is a constant factor.

In these scenarios, advantages like energy saving through high light reflectance and enhanced corrosion resistance (due to the PVC layer protecting the gypsum core) are highly valued by project stakeholders.

Technical Advantages of PVC Gypsum Ceiling Systems

The distinctive composition of pvc gypsum ceiling systems confers several technical advantages that are highly beneficial in B2B applications:

- Superior Moisture Resistance: The PVC film acts as an effective barrier against humidity and water splashes, preventing the gypsum core from absorbing moisture. This mitigates issues like sagging, mold, mildew growth, and efflorescence, which are common with unprotected gypsum boards in damp environments.

- Enhanced Durability and Longevity: The robust PVC lamination provides a protective layer against physical impact, scratches, and abrasions, significantly extending the service life of the ceiling. This reduces the frequency and cost of maintenance and replacement.

- Exceptional Hygiene and Easy Maintenance: The smooth, non-porous surface of pvc laminated gypsum ceiling tiles is inherently resistant to dirt accumulation, bacterial growth, and chemical cleaning agents. It can be easily wiped clean with standard detergents, making it ideal for sterile and high-traffic areas.

- Fire Resistance Properties: Gypsum itself is a non-combustible material containing chemically combined water, which acts as a natural fire retardant. The addition of fire-rated gypsum cores enhances this property, providing valuable time for evacuation in the event of a fire, as certified by standards like ASTM E84.

- Thermal and Acoustic Performance: While standard gypsum offers baseline thermal and acoustic properties, the density of the gypsum core contributes to moderate thermal insulation and sound attenuation. Specialized pvc laminated gypsum ceiling board variants with acoustic backing or perforations can significantly improve Noise Reduction Coefficient (NRC) values.

- Aesthetic Versatility: PVC films are available in an extensive range of colors, patterns, and textures, including wood grains, metallic finishes, and various embossed designs. This allows for diverse architectural expressions without compromising functional benefits.

- VOC Compliance: Reputable manufacturers ensure their pvc gypsum ceiling products meet low VOC emission standards, contributing to healthier indoor air quality and compliance with green building initiatives.

These technical superiorities underscore why pvc laminated gypsum board price points often represent a sound investment in long-term building performance and reduced operational costs.

Vendor Comparison and Selection Criteria

Selecting the right supplier for pvc gypsum ceiling products is crucial for project success. A robust vendor comparison considers not just the pvc laminated gypsum board price but also quality, reliability, and service. Here's a framework for evaluation:

Key Vendor Evaluation Criteria:

By thoroughly evaluating these criteria, businesses can confidently select a supplier that provides high-quality pvc gypsum ceiling tiles and aligns with their project requirements and values.

Customized Solutions for Unique Project Demands

Many B2B projects require more than off-the-shelf solutions. Leading manufacturers of pvc gypsum ceiling understand this need and offer extensive customization capabilities to meet specific architectural and functional demands.

Areas of Customization:

- Dimensions and Edge Details: Beyond standard sizes, custom lengths and widths can minimize waste and optimize installation. Edge options, such as square, tegular, or rebated edges, can be tailored to fit various grid systems and aesthetic preferences.

- Aesthetic Finishes: The PVC film allows for unparalleled design flexibility. This includes a vast palette of solid colors, subtle textures, high-gloss or matte finishes, and even custom-printed patterns (e.g., company logos, abstract designs) to align with specific brand identities or interior themes.

- Performance Enhancements:

- Acoustic Optimization: Incorporating perforated gypsum cores or factory-applied acoustic fleece/tissue backing can significantly boost sound absorption, making pvc laminated gypsum ceiling tiles suitable for spaces requiring superior sound control (e.g., auditoriums, conference rooms).

- Moisture & Humidity Resistance: For extremely wet environments, specialized water-resistant gypsum cores combined with advanced PVC films and edge sealing provide enhanced protection against moisture damage.

- Fire Rating: Thicker gypsum cores or specific fire-rated gypsum types can be used to meet stringent fire safety classifications for particular building zones.

- Anti-Microbial Treatment: For healthcare or food processing sectors, PVC films can be treated with anti-bacterial or anti-fungal agents to inhibit microbial growth, bolstering hygiene.

- Integrated Backing: Options like aluminum foil backing can be added to the reverse side of the pvc laminated gypsum ceiling board to provide additional thermal insulation and moisture barrier properties, contributing to energy efficiency.

Working closely with a manufacturer like Xingyuan Ceilings, known for its extensive product portfolio and R&D capabilities, ensures that even the most complex project requirements for pvc gypsum ceiling are addressed with tailor-made, high-performance solutions.

Application Case Studies & Customer Experience

Real-world application demonstrates the tangible benefits and reliability of pvc gypsum ceiling systems. Below are illustrative scenarios:

Case Study 1: Large Hospital Redevelopment Project

Challenge: A major hospital expansion in Southeast Asia required a ceiling system that met stringent hygiene standards, offered excellent moisture resistance in clinical areas, and could be easily disinfected, while also providing a clean, bright aesthetic across patient rooms and corridors.

Solution: Over 15,000 square meters of 9.0mm thick pvc laminated gypsum ceiling tiles with an anti-microbial PVC film and aluminum foil backing were specified. The tiles were installed in operating theaters, patient rooms, and corridors. The smooth, non-porous surface facilitated daily cleaning and disinfection, crucial for infection control. The inherent moisture resistance prevented issues in high-humidity zones like washrooms and utility areas.

Outcome: The project was completed on schedule, and the facilities management team reported a significant reduction in maintenance effort compared to previous ceiling materials. Occupant feedback highlighted the bright, clean appearance and improved indoor environmental quality. The system's durability has ensured sustained performance over five years without visible degradation, validating the initial pvc laminated gypsum board price investment.

Case Study 2: Corporate Office Fit-out

Challenge: A multinational corporation sought a ceiling solution for its new regional headquarters that offered a modern aesthetic, excellent light reflectance to reduce energy consumption, and sound attenuation for open-plan offices and meeting rooms. Ease of access to plenum for IT and HVAC maintenance was also essential.

Solution: A bespoke solution of 7.5mm pvc laminated gypsum ceiling board with a high-reflectance, matte white PVC finish was selected. Specialized acoustically enhanced versions were deployed in meeting rooms and collaborative spaces. The standard T-grid suspension system allowed for easy integration of lighting and access for maintenance.

Outcome: The client praised the sleek, professional appearance of the ceilings, which significantly contributed to the contemporary office design. Energy audits demonstrated a measurable reduction in lighting electricity consumption due to the high light reflectance. Employee feedback indicated improved acoustic comfort in work areas, leading to enhanced productivity. This project underscored the aesthetic and functional flexibility of pvc gypsum ceiling tiles.

Trustworthiness: FAQs, Lead Time, Warranty, and Support

Transparency in product information, logistics, and after-sales support builds trust with B2B clients. Xingyuan Ceilings is committed to providing comprehensive support throughout the project lifecycle.

Frequently Asked Questions (FAQs):

- Q: Are pvc gypsum ceiling tiles suitable for high-humidity areas?

- A: Yes, the PVC lamination provides excellent moisture resistance, making them ideal for areas like bathrooms, kitchens, and other high-humidity environments where traditional gypsum might deteriorate. For extremely wet conditions, specialized moisture-resistant gypsum cores can be used.

- Q: How do pvc gypsum ceiling boards contribute to fire safety?

- A: The gypsum core is inherently non-combustible and contains chemically bound water that releases steam when exposed to high temperatures, retarding fire spread. Many of our pvc laminated gypsum ceiling tiles meet Class A (ASTM E84) fire ratings.

- Q: Can these ceilings be customized for specific aesthetic requirements?

- A: Absolutely. We offer extensive customization options for PVC film patterns, colors, textures, and even custom printing to match specific interior design themes or corporate branding. Contact our sales team for detailed customization possibilities.

- Q: What is the estimated pvc laminated gypsum board price range?

- A: The price varies based on thickness, dimensions, PVC film type, and order volume. We recommend requesting a formal quote tailored to your project specifications for the most accurate pricing. Our solutions offer excellent long-term value due to their durability and low maintenance.

Lead Time & Fulfillment Details:

Standard orders for pvc gypsum ceiling products typically have a lead time of 2-4 weeks from order confirmation, depending on volume and current production schedules. Custom orders may require additional time for material sourcing and specialized manufacturing. We operate a robust supply chain and logistics network to ensure timely and efficient delivery to project sites worldwide.

Warranty Commitments:

Xingyuan Ceilings stands behind the quality of its products. All pvc gypsum ceiling tiles come with a comprehensive 5-year limited warranty against manufacturing defects. This warranty covers material integrity and performance under normal installation and usage conditions. Extended warranty options may be available for specific projects or product lines.

Customer Support Information:

Our dedicated B2B customer support team is available to assist with product selection, technical specifications, order placement, and after-sales inquiries. We provide:

- Technical Consultation: Expert advice on optimal pvc gypsum ceiling solutions for your specific project needs.

- Project Management Support: Assistance from initial inquiry to post-installation follow-up.

- Responsive Communication: Multi-channel support via email, phone, and online portal for quick query resolution.

- Documentation: Access to comprehensive product data sheets, installation guides, and certifications.

Conclusion

The pvc gypsum ceiling stands as a premier solution for modern commercial and industrial environments, balancing advanced technical performance with aesthetic adaptability. Its superior moisture resistance, hygiene characteristics, durability, and fire safety compliance make it an ideal choice for a diverse range of B2B applications. By partnering with reputable manufacturers that prioritize quality, customization, and comprehensive support, businesses can leverage the full potential of pvc laminated gypsum ceiling tiles to create functional, resilient, and visually appealing spaces.

As the construction industry continues to evolve, the demand for high-performance, sustainable, and cost-effective ceiling solutions will only grow. PVC gypsum ceiling systems are well-positioned to meet these challenges, offering a sophisticated blend of material science and design innovation.

References

- ASTM International. (2020). ASTM E84: Standard Test Method for Surface Burning Characteristics of Building Materials. ASTM International, West Conshohocken, PA.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems — Requirements. ISO, Geneva, Switzerland.

- US Green Building Council. (2023). LEED v4.1 Building Design and Construction Reference Guide. U.S. Green Building Council, Washington, D.C.

- Gypsum Association. (2018). GA-216: Application of Gypsum Panel Products. Gypsum Association, Hyattsville, MD.

-

PVC Gypsum Ceiling: Durable, Laminated Tiles for Modern SpacesNewsAug.28,2025

-

Pvc Gypsum Ceiling Is DurableNewsAug.21,2025

-

Mineral Fiber Board Is DurableNewsAug.21,2025

-

Ceiling Tile Clip Reusable DesignNewsAug.21,2025

-

Ceiling T Grid Modular DesignNewsAug.21,2025

-

Ceiling Hatch Key Mandatory ToolNewsAug.21,2025