- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

ነሐሴ . 13, 2025 03:20 Back to list

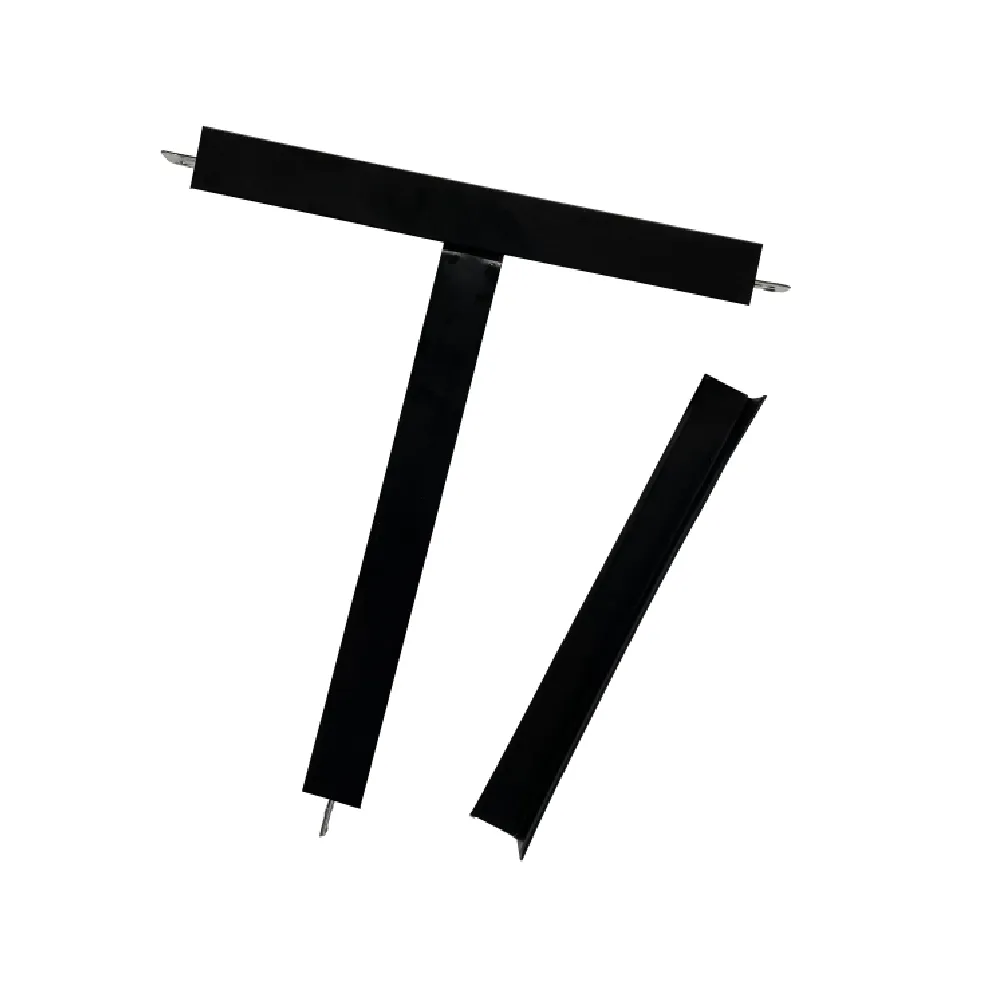

Quality Ceiling T Grid & Cross Tee for Suspended Ceilings

Understanding the Evolution and Impact of Modern Ceiling Suspension Systems

In contemporary architectural design and construction, the choice of ceiling suspension systems plays a pivotal role in both aesthetics and functionality. The ceiling t grid system stands as a cornerstone technology, offering unparalleled versatility and efficiency for various commercial, institutional, and industrial applications. This sophisticated framework not only provides robust support for acoustic and gypsum ceiling tiles but also facilitates easy access to the plenum space for maintenance of HVAC, electrical, and plumbing systems. The evolution of grid ceiling materials has been driven by demands for increased load-bearing capacity, improved corrosion resistance, enhanced fire safety, and greater design flexibility, moving beyond rudimentary installations to highly engineered solutions that meet stringent industry standards.

The market for suspended ceiling systems, including advanced ceiling t grid solutions, continues to experience steady growth, propelled by the increasing global construction activity and a growing emphasis on modular, sustainable building practices. Key trends include the adoption of lightweight yet strong materials, integration of smart building technologies, and a heightened focus on indoor air quality and acoustic performance. These innovations are crucial for creating healthy, productive, and adaptable environments. Understanding the intricate details of these systems, from their manufacturing processes to their performance benchmarks, is essential for architects, engineers, and procurement professionals seeking optimal solutions for their projects.

Technical Specifications and Performance Metrics of Ceilings T Grid Suspended System

The performance of any suspended ceiling system, including the advanced Ceilings t grid Suspended System, is predicated on its adherence to precise technical parameters and rigorous quality control. Our ceiling t grid system is meticulously engineered to ensure superior structural integrity and longevity. Key components such as main runners and cross tees are designed with specific dimensions and load-bearing capabilities to accommodate various ceiling tile weights and supplementary loads, such as lighting fixtures or air diffusers. The choice of grid ceiling material, typically high-grade galvanized steel or aluminum, is critical for resisting corrosion and ensuring fire safety compliance.

Below is a comprehensive table detailing the typical technical specifications for a standard Ceilings t grid Suspended System, illustrating the precision and quality inherent in our products. These parameters are crucial for ensuring the system's compatibility with diverse architectural designs and functional requirements. For instance, the cross tee ceiling components are designed for seamless integration and robust connections, minimizing deflection and ensuring a level ceiling plane.

| Parameter | Specification | Industry Standard / Test Method |

|---|---|---|

| Material Composition | Hot-dipped galvanized steel (HDG) or Aluminum Alloy | ASTM A653 / JIS G3302 |

| Thickness (Main Runner) | 0.26mm - 0.40mm | EN 10346 |

| Standard Length (Main Runner) | 3600mm / 144 inches | ASTM C635 Tolerances |

| Standard Length (Cross Tee) | 1200mm / 48 inches (Long), 600mm / 24 inches (Short) | ASTM C635 Tolerances |

| Width of Flange | 24mm / 15mm | Manufacturing Standard |

| Load-Bearing Capacity | Up to 15 kg/m² (Light-Duty), 20 kg/m² (Intermediate-Duty), 25 kg/m² (Heavy-Duty) | ASTM C635 (Deflection Criteria) |

| Fire Rating | Class A (Non-combustible) per ASTM E84, or specified fire resistance ratings | UL 263 / ASTM E119 |

| Corrosion Resistance | Minimum 120 hours salt spray (ASTM B117) for galvanized finishes | ASTM B117 |

| Surface Finish | Pre-painted white, black, or custom colors; hot-dip galvanized coating | Visual Inspection / Adhesion Test |

Precision Manufacturing Process of Ceiling T Grid

The production of high-quality ceiling t grid components involves a sophisticated multi-stage manufacturing process, ensuring precision, durability, and compliance with international standards such as ISO 9001 for quality management and relevant ASTM/ANSI specifications. The core of the process begins with the careful selection of raw materials, primarily high-grade hot-dipped galvanized steel coils or aluminum, chosen for their inherent strength and corrosion resistance. These materials are critical to the longevity and performance of the final ceiling t grid system.

The initial stage, known as roll forming, shapes the flat metal strips into the distinctive T-profile of the main runners and cross tees. This process utilizes a series of precisely calibrated rollers to gradually bend the metal, creating a consistent and accurate profile. Following roll forming, advanced punching and stamping machines create the necessary connection holes, notches, and slots for the interlocking system that defines the cross tee ceiling structure. Automated systems ensure high precision and repeatability, crucial for ease of installation on site.

Surface treatment is a vital step, typically involving pre-painting with a durable polyester or epoxy coating for aesthetic finishes and enhanced corrosion protection. This coating is applied uniformly to ensure long-term visual appeal and resistance to environmental factors. Post-coating, the components undergo rigorous quality inspection, including dimensional checks, load-bearing tests to verify compliance with ASTM C635/C636, and salt spray tests (e.g., ASTM B117) to assess corrosion resistance. These stringent tests ensure a product lifespan typically exceeding 20 years under normal indoor conditions. This robust manufacturing approach ensures the Ceilings t grid Suspended System offers superior performance in a wide range of applicable industries, from commercial offices and healthcare facilities to educational institutions and retail spaces, providing significant advantages in terms of long-term durability and low maintenance.

Diverse Application Scenarios and Key Advantages

The adaptability and technical superiority of the Ceilings t grid Suspended System make it an ideal choice across a myriad of application scenarios. From high-traffic commercial offices and bustling retail environments to critical healthcare facilities and dynamic educational institutions, the ceiling t grid provides a robust and visually appealing foundation for various ceiling materials. Its modular design allows for rapid installation, significantly reducing project timelines and associated labor costs, a critical factor for large-scale developments where efficiency is paramount.

A primary advantage lies in its superior accessibility to the plenum space. Unlike traditional solid ceilings where access for maintenance or modifications to HVAC, electrical, or plumbing systems requires invasive and costly demolition, a ceiling t grid system with removable tiles offers unparalleled ease of access. This translates into reduced downtime for building occupants and lower long-term operational costs for facilities management. Furthermore, the system inherently supports excellent acoustic performance when paired with appropriate acoustic ceiling tiles, contributing to improved indoor soundscapes essential for productivity and comfort.

When considering factors like drywall ceiling grid price versus the total installed cost of a suspended system, it's vital to assess the long-term benefits of flexibility and maintenance. While initial material costs for drywall systems might appear lower, the total cost of ownership, including future modifications and maintenance, often favors suspended grid systems. The system also excels in fire resistance, with components designed to maintain structural integrity during fire events, providing crucial time for evacuation and fire suppression. Its compatibility with a wide range of ceiling tiles, including mineral fiber, gypsum, and metal, ensures design versatility and the ability to meet diverse aesthetic and functional requirements. For projects considering alternatives like gridstone ceiling tile cost, our ceiling t grid provides the reliable and durable framework for such installations, ensuring stability and performance.

Competitive Edge and Product Value Proposition

In a competitive market, understanding the distinct value proposition of a ceiling t grid system is crucial. Our Ceilings t grid Suspended System differentiates itself through a combination of superior material quality, precision engineering, and adherence to global performance standards. While various options exist, including those affecting drywall ceiling grid price or different types of grid ceiling material, our focus remains on delivering a product that offers optimal long-term value, reliability, and ease of installation.

| Feature/Benefit | Ceilings T Grid Suspended System (Xingyuan Ceilings) | Standard Market Offerings |

|---|---|---|

| Material Grade | Premium Hot-Dipped Galvanized Steel (Z275 coating) / High-Strength Aluminum | Common Galvanized Steel (Z180-Z220 coating) |

| Corrosion Resistance | Excellent; exceeds 120-hour salt spray test (ASTM B117) | Moderate; typically meets minimum 96-hour salt spray |

| Load-Bearing Capacity | Certified Intermediate-Duty to Heavy-Duty (ASTM C635) | Often Light-Duty to Intermediate-Duty |

| Connection Type (Cross Tee) | Precise Hook/Rivet or Patented Clip-In System for enhanced stability | Standard Hook/Rivet System |

| Installation Speed | Optimized interlocking design for rapid, tool-free assembly | Standard installation time |

| Certifications | ISO 9001, ASTM C635/C636, Fire-rated (UL listed components) | Varies; may meet only basic local standards |

| Lifespan & Warranty | 20+ years lifespan; comprehensive manufacturer warranty | Shorter typical lifespan; limited warranty |

This comparison highlights our commitment to delivering superior quality that translates into enhanced safety, reduced maintenance costs, and extended product life. Our cross tee ceiling components, in particular, are engineered for seamless interlocking, providing a stable and level ceiling plane that resists sag and deformation over time. This technical advantage ensures that the initial investment in our Ceilings t grid Suspended System yields significant long-term returns through reduced operational expenditure and enhanced aesthetic durability.

Tailored Customization and Project Solutions

Recognizing that every project presents unique challenges and design aspirations, the Ceilings t grid Suspended System offers extensive customization options beyond standard dimensions and finishes. Our engineering team collaborates closely with clients to develop bespoke ceiling t grid solutions that perfectly align with specific architectural visions and functional requirements. This includes, but is not limited to, custom lengths for main runners and cross tees to minimize waste and optimize installation efficiency for unusual room dimensions.

Custom finishes and colors are available to match interior design palettes, offering options beyond standard white or black. For projects requiring enhanced environmental performance, specialized coatings for increased humidity resistance or anti-microbial properties can be integrated, making our ceiling t grid ideal for healthcare or laboratory environments. We also provide support for integrating specialized fixtures, such as seismic bracing for earthquake-prone regions, or reinforcement for heavy light fixtures and air handling units, ensuring structural integrity and safety. Our capabilities extend to providing full project support, from initial design consultation and material specification to logistical planning and delivery, ensuring a seamless experience for our B2B partners. This consultative approach empowers clients to leverage the full potential of a customized cross tee ceiling system.

Case Studies and Real-World Applications

The proven reliability and versatility of the Ceilings t grid Suspended System are best demonstrated through its successful implementation in diverse and demanding environments. Our ceiling t grid has been deployed in numerous large-scale projects, showcasing its adaptability and superior performance. For instance, in a recent project involving a multi-story corporate headquarters, the rapid installation capabilities of our ceiling t grid system were instrumental in meeting aggressive construction deadlines. The client specifically lauded the system's ease of integration with intelligent lighting and advanced HVAC systems, providing accessible plenum space for seamless future upgrades.

Another notable application involved a state-of-the-art hospital facility, where stringent requirements for hygiene, durability, and fire safety were paramount. Our specially coated ceiling t grid components, combined with anti-microbial ceiling tiles, provided an easily cleanable and robust solution that contributed to maintaining sterile environments. The system's capacity to support heavy medical equipment integrated into the ceiling, alongside its seismic bracing capabilities, provided peace of mind for the facility's operators. Feedback from these projects consistently highlights the long-term cost-effectiveness and operational advantages derived from the ceiling t grid system, underscoring its value beyond initial installation cost considerations, particularly when evaluating overall expenses compared to options like drywall ceiling grid price or gridstone ceiling tile cost.

Frequently Asked Questions (FAQ) about Ceiling T Grid Systems

-

Q: What is the primary material used in your ceiling t grid system?

A: Our ceiling t grid systems are primarily manufactured from high-grade hot-dipped galvanized steel, which offers exceptional strength and corrosion resistance. We also offer aluminum options for specific applications requiring lightweight or non-ferrous properties.

-

Q: How does your ceiling t grid system ensure fire safety?

A: Our ceiling t grid components are designed to meet or exceed international fire safety standards, including ASTM E84 Class A ratings for surface burning characteristics. Key components are often UL-listed or certified by other recognized authorities for their fire-resistance properties, providing crucial structural integrity during a fire event.

-

Q: Can the ceiling t grid system accommodate heavy light fixtures or HVAC ducts?

A: Yes, our ceiling t grid systems are engineered with different load-bearing capacities (light, intermediate, heavy-duty) to support various ceiling tile types and supplementary loads such as light fixtures, air diffusers, and sprinkler heads. For heavier loads, additional bracing or specific grid configurations can be designed.

-

Q: What are the typical lead times for large orders of ceiling t grid?

A: Lead times vary depending on the order size, customization requirements, and current production schedule. Typically, standard orders can be fulfilled within 2-4 weeks. We recommend contacting our sales team directly for precise lead time estimates for specific project requirements.

Logistics, Warranty, and Customer Support Excellence

At Xingyuan Ceilings, we understand that product quality extends beyond manufacturing to encompass reliable logistics and robust customer support. Our streamlined supply chain ensures efficient delivery of your ceiling t grid components to project sites worldwide. We provide detailed delivery schedules and work closely with logistics partners to guarantee on-time arrivals, minimizing any potential delays to your construction timeline. Our packaging is designed to protect components from damage during transit, ensuring that the ceiling t grid arrives in pristine condition, ready for immediate installation.

We stand behind the superior quality of our Ceilings t grid Suspended System with a comprehensive warranty that covers manufacturing defects and material integrity for an extended period, typically 10 to 20 years depending on the specific product line and application. This commitment reflects our confidence in the durability and performance of our ceiling t grid products, providing our clients with long-term peace of mind. Our dedicated customer support team is readily available to assist with technical queries, product selection, installation guidance, and any post-purchase requirements. We are committed to building lasting partnerships by offering unparalleled service and support throughout the entire project lifecycle, ensuring that every cross tee ceiling installation is a success.

References

- American Society for Testing and Materials (ASTM) International. (2018). ASTM C635/C635M-18, Standard Specification for Manufacture, Performance, and Testing of Metal Suspension Systems for Acoustical Tile and Lay-in Panel Ceilings. West Conshohocken, PA: ASTM International.

- European Committee for Standardization (CEN). (2014). EN 13964:2014, Suspended ceilings - Requirements and test methods. Brussels, Belgium: CEN.

- International Organization for Standardization (ISO). (2015). ISO 9001:2015, Quality management systems — Requirements. Geneva, Switzerland: ISO.

- Underwriters Laboratories (UL) Inc. (2020). UL 263, Standard for Fire Tests of Building Construction and Materials. Northbrook, IL: UL.

- U.S. General Services Administration (GSA). (2018). Facilities Standards for the Public Buildings Service (P100), Chapter 7: Interior Finishes. Washington, D.C.: GSA.

-

Mineral Fiber Ceiling Tiles Embossed Surface PatternNewsAug.05,2025

-

Mineral Fiber Board Xingyuan Vision for Better SpacesNewsAug.05,2025

-

Drop Down Ceiling Tile Office Use FitNewsAug.05,2025

-

PVC Gypsum Ceiling White Base ColorNewsAug.05,2025

-

Access Panel on Ceiling Xingyuan Integrity EthicNewsAug.05,2025

-

Ceiling Trap Doors Fire Resistant DesignNewsAug.05,2025