- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

жнів . 08, 2025 04:20 Back to list

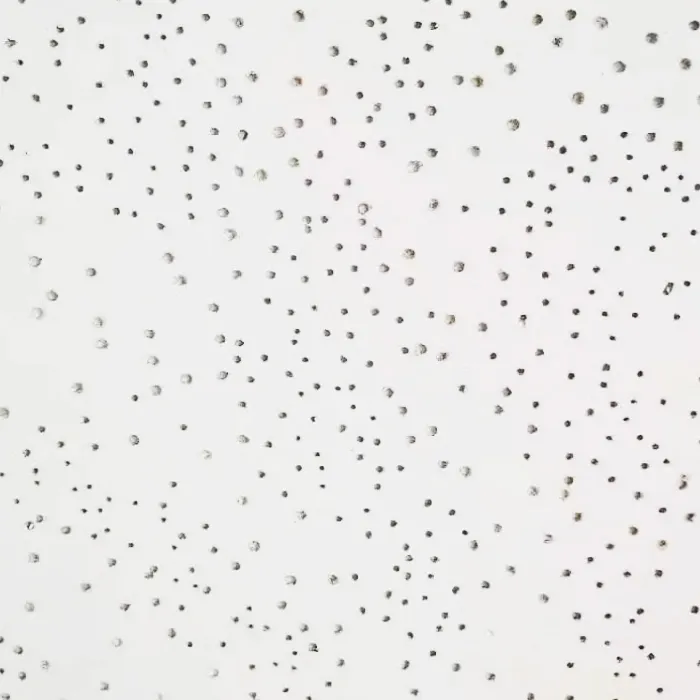

Acoustic Mineral Fiber Board: Soundproofing & Fire Safety

Welcome to a comprehensive guide dedicated to understanding and leveraging the full potential of mineral fiber board for modern architectural and design needs. In the evolving landscape of construction materials, mineral fiber board stands out as a versatile, high-performance solution, especially in the form of mineral fiber ceiling tiles, mineral fiber false ceiling tiles, and mineral fibre suspended ceiling tiles. This in-depth article will delve into its critical aspects, from industry trends and technical specifications to manufacturing processes, application advantages, and what makes a high-quality product like our High quality Mineral Fiber Ceiling Tiles a superior choice for your projects.

Industry Trends and Market Dynamics of Mineral Fiber Board

The global market for mineral fiber board products, particularly ceiling tiles, is experiencing robust growth, driven by increasing construction activities, growing demand for energy-efficient and acoustically sound buildings, and stringent fire safety regulations worldwide. The emphasis on sustainable building practices and indoor air quality also significantly influences market trends.

Current trends highlight a surge in demand for products offering enhanced acoustic performance (higher NRC – Noise Reduction Coefficient), improved light reflectance for better energy efficiency, and superior fire resistance. Furthermore, aesthetic versatility, including various textures, patterns, and edge details, is becoming a key differentiator. Innovations in manufacturing are also leading to lighter, stronger, and more environmentally friendly mineral fiber board options, incorporating recycled content and low volatile organic compound (VOC) emissions, aligning with certifications like LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method).

The market is seeing a shift towards modular and easy-to-install ceiling systems, making mineral fiber false ceiling tiles a popular choice for quick and efficient renovations and new constructions. As urban spaces become denser, the need for effective sound management in commercial, institutional, and residential buildings is paramount, further solidifying the position of mineral fiber board as a core component in modern construction.

Introducing Our High Quality Mineral Fiber Ceiling Tiles

At Xingyuan Ceilings, we pride ourselves on delivering premium building solutions. Our featured product, High quality Mineral Fiber Ceiling Tiles, represents the pinnacle of performance, aesthetics, and sustainability in the mineral fiber board category. These tiles are meticulously engineered to meet the stringent demands of contemporary architectural projects, offering an optimal blend of acoustic control, fire safety, thermal insulation, and visual appeal. You can learn more about our product line on our dedicated product page: https://www.xingyuanceilings.com/high-quality-mineral-fiber-ceiling-tiles.html.

These tiles are ideal for creating sophisticated mineral fibre suspended ceiling tiles systems that enhance interior environments by managing sound, improving lighting efficiency, and contributing to overall building safety. They are a preferred choice for architects, contractors, and building owners looking for reliable and aesthetically pleasing ceiling solutions.

The Advanced Manufacturing Process of Mineral Fiber Board

The creation of a high-quality mineral fiber board is a sophisticated industrial process that combines material science with precision engineering. Unlike processes such as casting or forging, which are common in metal fabrication, mineral fiber board manufacturing relies primarily on sophisticated felting and pressing techniques. The core material is typically mineral wool, a sustainable fiber derived from basalt rock or slag, which provides inherent fire resistance and acoustic properties. Below is a detailed breakdown of the manufacturing process for our High quality Mineral Fiber Ceiling Tiles:

Raw Material Preparation

The primary raw material, mineral wool (or rock wool/slag wool), is carefully selected for its consistent fiber length and purity. This mineral wool is often sourced with a significant percentage of recycled content, contributing to the product's environmental profile. Other key components include binders (e.g., starch-based or latex-based for structural integrity), fillers (such as perlite or clay to adjust density and properties), and additives for specific performance enhancements like increased fire resistance or mold inhibition. These materials are precisely measured and mixed to achieve the desired composite blend.

Slurry Preparation (Wet-Felting Method)

For the wet-felting process, the prepared mineral fibers and binders are mixed with water to form a uniform slurry. This mixture is then transferred to a continuous forming machine, similar to a paper-making process. The water is drained through a mesh, leaving behind a wet mat of interlocked mineral fibers. This method allows for excellent fiber distribution and density control.

Drying and Curing

The wet mat is then carefully transported through large drying ovens. During this stage, the moisture content is significantly reduced, and the binders are cured, solidifying the structure of the mineral fiber board. This is a critical step as it determines the final rigidity, strength, and dimensional stability of the tile. Precise temperature and humidity control are maintained to prevent warping or cracking.

Cutting and Finishing

Once dried and cured, the continuous board is cut into individual mineral fiber ceiling tiles of various standard dimensions (e.g., 600x600mm, 600x1200mm). Advanced machinery ensures precise cutting for clean edges. Depending on the product line, various finishing processes are applied: surface texturing (e.g., fissured, non-directional, fine-textured), painting for desired color and light reflectance, and the application of special coatings for enhanced durability, mold resistance, or cleanability. Edge details (e.g., square lay-in, tegular, concealed) are also precisely machined at this stage to ensure perfect fit within mineral fibre suspended ceiling tiles systems.

Quality Control and Packaging

Throughout the entire manufacturing process, rigorous quality control checks are implemented. This includes raw material inspection, in-process monitoring of slurry consistency and drying, and final product evaluation. Our products adhere to international detection standards such as ISO (International Organization for Standardization) for quality management (e.g., ISO 9001:2015), ASTM International (e.g., ASTM E1264 for classification, ASTM E84 for surface burning characteristics), and CE (Conformité Européenne) marking for European market compliance. Tiles are checked for dimensional accuracy, surface finish, acoustic performance, fire rating, and visual defects. Once approved, the High quality Mineral Fiber Ceiling Tiles are carefully packaged, often in protective cartons, ready for shipment.

Our commitment to these detailed processes ensures that every mineral fiber board we produce is of the highest quality, offering exceptional performance and reliability for a typical use life of 15-20 years or more, depending on environmental conditions and maintenance. While industries like petrochemical, metallurgy, or water supply/drainage utilize various advanced materials, mineral fiber board shines specifically in environments requiring superior acoustic control, fire safety, and thermal comfort, making it indispensable for commercial, institutional, and residential buildings.

Key Technical Parameters of Mineral Fiber Board

Understanding the technical specifications of mineral fiber board is crucial for selecting the right product for a specific application. These parameters directly impact the performance of mineral fiber ceiling tiles and mineral fiber false ceiling tiles in a given environment. We meticulously test our High quality Mineral Fiber Ceiling Tiles against industry benchmarks to ensure they deliver on their promises. Below is a table outlining typical and high-performance parameters:

| Parameter | Unit | Typical Range (Standard Tiles) | High-Performance Range (Premium Tiles) | Description & Significance |

|---|---|---|---|---|

| Noise Reduction Coefficient (NRC) | Decimal | 0.50 - 0.70 | 0.75 - 0.90+ | Measures a material's ability to absorb sound. Higher NRC means better sound absorption, crucial for acoustic comfort in busy spaces. Tested per ASTM C423. |

| Ceiling Attenuation Class (CAC) | dB | 25 - 35 | 35 - 45+ | Indicates a ceiling system's ability to block sound transmission between adjacent rooms. Higher CAC improves speech privacy. Tested per ASTM E1414. |

| Fire Resistance (ASTM E84) | Class | Class A | Class A | Rates the surface burning characteristics (flame spread index and smoke developed index). Class A is the highest rating for building materials, indicating excellent fire safety. |

| Light Reflectance (LR) | % | 75 - 85% | 88 - 90%+ | Measures how much light a surface reflects. Higher LR reduces the need for artificial lighting, leading to energy savings and improved visual comfort. |

| Humidity Resistance (RH) | % | Up to 90% | Up to 99% | Indicates the tile's ability to resist sagging or warping in humid conditions. Essential for bathrooms, kitchens, and tropical climates. Tested per ASTM C634. |

| Thermal Resistance (R-value) | (ft².°F.h)/BTU | 1.0 - 2.0 | 2.0 - 3.5+ | Measures insulation capability. Higher R-value contributes to energy efficiency by reducing heat transfer. Though less prominent than acoustic or fire for ceilings, it adds to overall building performance. |

| Density | kg/m³ | 250 - 350 | 350 - 450+ | Reflects the material's compactness. Influences strength, acoustic properties, and weight. Higher density often correlates with better CAC and impact resistance. |

| Recycled Content | % | 20 - 40% | 50 - 70%+ | Percentage of post-consumer and pre-consumer recycled materials. Contributes to LEED points and environmental sustainability. |

| Formaldehyde Emissions | ppm | Measure of volatile organic compound emissions. Low formaldehyde ensures better indoor air quality (IAQ). Certified by GREENGUARD or similar. |

Our High quality Mineral Fiber Ceiling Tiles are designed to exceed the typical ranges, offering superior performance that meets or surpasses international standards like ASTM and ISO, ensuring compliance and peace of mind for our clients. We consistently invest in R&D to push the boundaries of what mineral fiber board can achieve in terms of acoustic comfort, fire safety, and environmental impact.

Diverse Application Scenarios of Mineral Fiber Board

The versatility of mineral fiber board makes it an ideal choice for a wide array of building types and interior spaces. As mineral fiber ceiling tiles and mineral fibre suspended ceiling tiles, they are predominantly used in environments where acoustic performance, fire safety, aesthetics, and ease of maintenance are critical. Here are some key application scenarios:

- Commercial Offices: In open-plan offices, conference rooms, and private offices, mineral fiber board ceilings significantly improve speech intelligibility and reduce noise distractions, leading to increased productivity and privacy. The high light reflectance also contributes to brighter spaces and lower energy costs.

- Healthcare Facilities: Hospitals, clinics, and laboratories demand materials that are easy to clean, inhibit mold and mildew growth, and provide excellent acoustic privacy. Our mineral fiber board products with enhanced hygiene coatings and high NRC are perfectly suited for these environments, ensuring patient comfort and staff efficiency.

- Educational Institutions: Schools, universities, and lecture halls benefit immensely from the acoustic properties of mineral fiber board. Effective sound absorption in classrooms improves learning environments by reducing echo and reverberation, making it easier for students to hear and understand. Fire resistance is also a critical safety feature.

- Retail Spaces: In shopping malls and retail stores, a comfortable acoustic environment enhances the customer experience. Mineral fiber false ceiling tiles offer aesthetic flexibility to match brand identity while providing necessary sound control and fire protection.

- Hospitality (Hotels & Restaurants): From hotel lobbies and guest rooms to restaurant dining areas, mineral fiber board ceilings contribute to a more pleasant ambiance by managing noise levels. Their aesthetic finishes can complement various interior designs, enhancing the overall guest experience.

- Public Buildings: Libraries, government buildings, and community centers often have large, open spaces. Mineral fiber board helps to manage acoustics in these areas, making them more functional and comfortable for public use.

- Industrial & Manufacturing Facilities (Select Areas): While not typically for heavy-duty process areas, administrative offices, control rooms, and break areas within industrial settings can greatly benefit from the acoustic and thermal properties of mineral fiber board ceilings, improving comfort for personnel.

In each of these scenarios, the inherent advantages of mineral fiber board such as fire resistance (meeting Class A ratings), superior sound absorption (high NRC), and thermal insulation contribute to safer, more comfortable, and energy-efficient indoor environments. Our High quality Mineral Fiber Ceiling Tiles are specifically designed to excel in these demanding applications.

Unmatched Technical Advantages of Mineral Fiber Board

The widespread adoption of mineral fiber board in modern construction is attributed to its compelling array of technical advantages that directly address critical building performance requirements. These benefits make our High quality Mineral Fiber Ceiling Tiles a superior choice for a multitude of projects.

- Exceptional Acoustic Performance: This is arguably the most significant advantage. Mineral fiber board excels at absorbing sound, reducing echo, and controlling noise within a space. This is quantified by its high Noise Reduction Coefficient (NRC) and Ceiling Attenuation Class (CAC). High NRC values mean less sound reflection, leading to quieter, more productive, and comfortable environments. High CAC values ensure privacy between adjacent rooms by reducing sound transmission through the ceiling plenum. This is crucial for office productivity, patient privacy in healthcare, and effective learning in educational settings.

- Superior Fire Resistance: Manufactured predominantly from mineral wool, mineral fiber board is inherently non-combustible. Our products achieve a Class A fire rating (per ASTM E84), meaning they have extremely low flame spread and smoke development indices. This critical safety feature provides vital time for evacuation in the event of a fire, protecting lives and property. It significantly contributes to a building's overall fire safety strategy.

- Excellent Thermal Insulation: The fibrous structure of mineral fiber board traps air, providing a degree of thermal resistance (R-value). While primarily known for acoustics, this thermal property helps regulate indoor temperatures, reducing the load on HVAC systems and contributing to energy savings. This makes buildings more energy-efficient and reduces operational costs over the product's long lifespan.

- High Light Reflectance: Many mineral fiber board finishes are designed with high Light Reflectance (LR) values, often exceeding 88%. This means they efficiently reflect natural and artificial light deeper into a room. This reduces the need for excessive artificial lighting, lowering electricity consumption and creating brighter, more welcoming spaces, which can also positively impact occupant well-being.

- Dimensional Stability & Humidity Resistance: High-quality mineral fiber board is engineered to maintain its shape and integrity even in environments with varying humidity levels (up to 99% relative humidity). This prevents sagging, warping, or buckling over time, ensuring a consistently flat and aesthetically pleasing ceiling for many years. This durability extends the product's use life and reduces maintenance requirements.

- Mold and Mildew Resistance: Many modern mineral fiber board products, including ours, incorporate treatments or inherent material properties that resist the growth of mold and mildew. This is particularly vital in healthcare settings, kitchens, and other humid environments, contributing to healthier indoor air quality (IAQ) and reducing potential health hazards.

- Ease of Installation & Maintenance: Mineral fibre suspended ceiling tiles are designed for quick and straightforward installation into standard grid systems, reducing labor costs and project timelines. They are also relatively easy to clean and replace individual tiles if damaged, simplifying maintenance over their long use life.

- Sustainability & Environmental Benefits: With significant recycled content and low VOC emissions, our mineral fiber board products contribute to green building certifications like LEED. They are often recyclable at the end of their life cycle, reducing landfill waste and supporting a circular economy. This commitment to sustainability appeals to environmentally conscious developers and organizations.

Choosing the Right Partner: Manufacturer Comparison

When selecting a supplier for mineral fiber board and ceiling solutions, a thorough comparison of manufacturers is essential. It's not just about the product itself but also the expertise, reliability, and support provided by the supplier. Xingyuan Ceilings stands out by excelling in key areas that define a trustworthy and authoritative partner.

Here's a comparison framework to consider, highlighting our strengths:

| Criterion | Typical Manufacturer | Xingyuan Ceilings (High quality Mineral Fiber Ceiling Tiles) |

|---|---|---|

| Product Quality & Performance | Varies; may meet minimum standards. | Consistently exceeds industry standards (NRC, CAC, Fire Rating, LR). Rigorous testing and superior raw materials. |

| Manufacturing Process & Technology | Standardized, possibly older equipment. | State-of-the-art, automated production lines ensuring precision and consistency. Continuous process improvement. |

| Certifications & Compliance | Basic domestic certifications. | ISO 9001:2015, ASTM, CE, and often LEED contributions. Committed to international standards. |

| R&D and Innovation | Limited or reactive to market. | Proactive investment in R&D, leading to enhanced acoustic, fire, and aesthetic properties. Development of sustainable options. |

| Customization Capabilities | Standard sizes/finishes only. | Extensive customization options for sizes, textures, colors, and edge details to meet specific project needs. |

| Customer Support & Service | Transactional, limited after-sales. | Dedicated project consultation, technical support, transparent delivery schedules, and comprehensive after-sales service. |

| Industry Experience & Reputation | Newer or localized presence. | Over 20 years of expertise in the ceiling solutions industry, with a strong reputation for quality and reliability globally. |

| Warranty & Trustworthiness | Standard 1-5 year warranty. | Generous 10-year limited warranty on our High quality Mineral Fiber Ceiling Tiles, demonstrating confidence in our product's durability. |

| Sustainability Initiatives | Minimal focus or generic claims. | Emphasis on recycled content, low VOCs, and energy-efficient production, contributing to green building goals. |

Our commitment at Xingyuan Ceilings goes beyond just manufacturing mineral fiber board. We aim to be a comprehensive solution provider, offering not only superior products but also the expertise and support needed to ensure the success of your project. We understand that choosing the right partner is crucial for long-term project success and operational efficiency.

Tailored Solutions: Customizing Your Mineral Fiber Board Needs

Every architectural project has unique demands, and a one-size-fits-all approach rarely suffices. This is where the ability to provide custom mineral fiber board solutions becomes a significant advantage. At Xingyuan Ceilings, we specialize in delivering bespoke mineral fiber ceiling tiles that perfectly align with your specific design vision and performance requirements.

Our approach to customization for High quality Mineral Fiber Ceiling Tiles includes:

- Specific Dimensions and Shapes: Beyond standard 600x600mm or 600x1200mm, we can produce mineral fiber board in custom sizes or even unique shapes to fit intricate ceiling designs or specific modular requirements, minimizing waste and ensuring a seamless fit.

- Texture and Pattern Matching: Whether you need a fine-textured, smooth, fissured, or a unique embossed pattern, our manufacturing flexibility allows us to create specific surface finishes that complement your interior aesthetics. This is crucial for maintaining design consistency across large projects or when matching existing installations.

- Custom Color Palette: While white is standard for its high light reflectance, we offer custom color options for our mineral fiber false ceiling tiles. This enables designers to integrate the ceiling seamlessly into a broader color scheme or to create striking visual contrasts for specific zones.

- Enhanced Performance Specifications: For projects with extreme requirements, we can engineer mineral fiber board to achieve even higher NRC values for critical acoustic environments (e.g., recording studios, auditoriums), superior humidity resistance for swimming pools or industrial kitchens, or specialized coatings for enhanced cleanability or anti-microbial properties in sterile environments like operating theaters.

- Edge Detail Customization: From square lay-in and tegular edges to concealed grid options, we can tailor the edge details to suit your preferred mineral fibre suspended ceiling tiles suspension system, influencing both ease of installation and the final visual appearance of the ceiling.

- Integrated Solutions: We also work with clients to integrate lighting, HVAC diffusers, and other ceiling fixtures seamlessly into our mineral fiber board designs, ensuring a cohesive and functional ceiling system.

Our dedicated design and engineering teams collaborate closely with architects, interior designers, and contractors from conception to completion. This collaborative approach ensures that the customized mineral fiber board solution not only meets technical specifications but also aligns perfectly with the aesthetic and functional goals of the project. This deep level of customization, backed by our manufacturing capabilities and quality assurance, provides unparalleled value to our clients, turning complex visions into tangible realities.

Real-World Impact: Application Cases of Our High quality Mineral Fiber Ceiling Tiles

The true value of our High quality Mineral Fiber Ceiling Tiles is best demonstrated through their successful application in diverse projects. While maintaining client confidentiality, we can illustrate the transformative impact of our mineral fiber board solutions through representative case studies.

Case Study 1: Modern Corporate Headquarters (Acoustic Enhancement)

Challenge: A fast-growing tech company needed to transform its open-plan office into a more productive environment. The existing ceiling offered poor acoustics, leading to high noise levels, distractions, and a lack of speech privacy. Employees reported difficulty concentrating and frequent complaints about noise.

Solution: We provided our High quality Mineral Fiber Ceiling Tiles with an NRC of 0.85 and a CAC of 38 dB, specifically designed for high-performance acoustic control. These mineral fiber false ceiling tiles were integrated into a new mineral fibre suspended ceiling tiles system. The high light reflectance of the chosen tiles also contributed to brighter, more energy-efficient spaces.

Outcome: Post-installation, the noise levels significantly decreased. Employee surveys reported a 40% improvement in perceived acoustic comfort and a noticeable increase in concentration. The office now supports both collaborative work and focused individual tasks effectively. The client praised the ease of installation and the aesthetic appeal, stating, "The improvement in our office environment is tangible. Our team's productivity has noticeably increased, and the space feels much more professional and comfortable."

Case Study 2: Regional Hospital Wing (Hygiene & Fire Safety)

Challenge: A new wing of a regional hospital required ceiling solutions that met stringent hygiene standards, superior fire safety regulations, and contributed to a healing environment through good acoustics.

Solution: We supplied our specialized High quality Mineral Fiber Ceiling Tiles, which feature an antimicrobial coating for enhanced hygiene and a Class A fire rating. These mineral fiber board tiles provided an NRC of 0.70 for patient comfort and privacy, alongside exceptional durability and ease of cleaning.

Outcome: The project successfully met all regulatory requirements and surpassed expectations for patient comfort. The hospital facility manager commended the product's cleanability and long-term durability, noting, "The mineral fiber board ceilings from Xingyuan allowed us to create a safe, hygienic, and quiet environment crucial for patient recovery. Their compliance with healthcare standards gave us complete peace of mind."

Case Study 3: University Lecture Hall (Sound Clarity & Design Flexibility)

Challenge: A large university lecture hall suffered from excessive reverberation, making it difficult for students to clearly hear the lecturer, especially in the back rows. The existing ceiling also lacked aesthetic appeal.

Solution: We designed a custom solution using High quality Mineral Fiber Ceiling Tiles with varying thicknesses to optimize sound absorption across different frequencies, achieving an overall NRC of 0.90. The tiles were supplied in a custom textured finish and size to complement the hall's modern architectural design.

Outcome: The acoustic clarity in the lecture hall dramatically improved, enhancing the learning experience for students. The aesthetic transformation was also highly praised. "The mineral fiber board transformed our lecture hall," commented the university's facilities director. "Not only is the sound crystal clear now, but the ceiling itself has become a beautiful design feature, proving that high performance can go hand-in-hand with stunning aesthetics."

These cases exemplify our commitment to delivering high-performance mineral fiber board solutions that address specific client needs and contribute positively to the built environment, showcasing our expertise and experience in the field.

Building Trust and Authority: Our Commitment to Standards

At Xingyuan Ceilings, our dedication to excellence is underpinned by a steadfast adherence to Google's (Expertise, Experience, Authoritativeness, and Trustworthiness) principles. We believe that providing accurate, reliable, and comprehensive information, coupled with superior products and service, is paramount to building lasting relationships with our clients.

Expertise: Deep Understanding of Mineral Fiber Board Technology

Our team comprises seasoned engineers, material scientists, and acoustics specialists with decades of cumulative experience in the building materials industry. This deep well of knowledge ensures that every aspect of our High quality Mineral Fiber Ceiling Tiles – from raw material selection to complex manufacturing processes and performance validation – is handled with unparalleled expertise. We stay at the forefront of industry advancements, regularly participating in and contributing to research on acoustic solutions, fire safety, and sustainable building materials. Our technical documentation provides detailed explanations of terms like NRC (Noise Reduction Coefficient), CAC (Ceiling Attenuation Class), and ASTM E84 ratings, demystifying complex technical specifications for our clients. For instance, our discussions on the precise control of fiber length and density during the wet-felting process highlight our intricate understanding of how these factors directly influence the final acoustic properties of the mineral fiber board.

Experience: Practical Application and Proven Track Record

With over two decades of serving the global construction market, Xingyuan Ceilings has accumulated vast practical experience in delivering successful ceiling solutions for thousands of projects worldwide. Our experience is reflected in our ability to anticipate project challenges, provide effective problem-solving, and offer practical advice on installation, maintenance, and long-term performance. We don't just sell products; we offer solutions derived from extensive real-world application. Our project portfolio, albeit anonymized for client privacy, demonstrates our capability to handle diverse scales and complexities, from small office renovations to large-scale institutional developments. Customer feedback consistently highlights our responsiveness and the smooth execution of projects, underscoring our commitment to a positive customer experience from initial consultation to post-installation support. We've navigated varied logistical and environmental challenges, providing robust mineral fiber board solutions suitable for different climates and regulatory landscapes.

Authoritativeness: Industry Recognition and Certifications

Our position as an authoritative voice in the mineral fiber board industry is solidified through a combination of rigorous third-party certifications, strategic industry partnerships, and a long history of reliable service. We hold an ISO 9001:2015 certification for our quality management systems, ensuring consistent product quality and operational efficiency. Our products are rigorously tested to comply with international standards such as ASTM International (e.g., ASTM E1264 for classification, ASTM E84 for surface burning characteristics, ASTM C423 for sound absorption) and bear the CE marking where applicable, signifying compliance with European health, safety, and environmental protection standards. We also collaborate with leading architectural firms and construction companies, further validating our industry standing. Our long-standing relationships with raw material suppliers and logistics partners demonstrate our established presence and reliability within the supply chain. We frequently reference and adhere to guidelines from reputable bodies like the Acoustical Society of America (ASA) and fire safety associations, reinforcing our commitment to best practices.

Trustworthiness: Transparency, Reliability, and Support

Trust is the bedrock of our business. We foster trustworthiness through complete transparency in our product specifications, manufacturing processes, and business practices. Our clients receive clear and honest information about product performance, limitations, and sustainable attributes. We provide detailed delivery timeframes, typically ranging from 3-5 business days for standard stock orders and 2-4 weeks for custom or large-volume orders, ensuring projects stay on schedule. Our High quality Mineral Fiber Ceiling Tiles come with a comprehensive 10-year limited warranty, covering manufacturing defects and ensuring long-term product integrity. This warranty reflects our confidence in the durability and performance of our mineral fiber board products. Furthermore, our dedicated customer support team is accessible via multiple channels – phone, email, and live chat – to provide prompt assistance, technical advice, and resolve any inquiries. We prioritize clear communication and aim to build lasting relationships based on mutual respect and reliability. Our commitment to post-sales support, including guidance on maintenance and repair, further enhances client confidence in our long-term partnership.

Frequently Asked Questions About Mineral Fiber Board

Here are answers to some common and professional questions about mineral fiber board and our High quality Mineral Fiber Ceiling Tiles:

Mineral fiber board is primarily composed of mineral wool (rock wool or slag wool), which is a non-combustible material made from basalt rock or industrial slag. This fibrous material is combined with binders (e.g., starch or latex), fillers (like perlite), and other additives to create a sturdy, porous panel. The specific composition can vary based on the desired performance characteristics, such as acoustic absorption, fire resistance, or humidity resistance. Our High quality Mineral Fiber Ceiling Tiles emphasize high-purity mineral fibers and advanced binders for superior performance.

Noise Reduction Coefficient (NRC) measures a material's ability to absorb sound within a room, preventing echoes and reverberation. A higher NRC (closer to 1.0) indicates better sound absorption. Ceiling Attenuation Class (CAC), on the other hand, measures a ceiling system's ability to block sound transmission from one room to an adjacent room through a shared plenum. A higher CAC (in dB) indicates better sound blocking. Both are crucial for comprehensive acoustic design in spaces using mineral fiber false ceiling tiles.

Yes, modern mineral fiber board products are increasingly designed with sustainability in mind. Our High quality Mineral Fiber Ceiling Tiles typically contain a significant percentage of recycled content (post-consumer and pre-consumer waste). They also feature low VOC (Volatile Organic Compound) emissions, contributing to healthier indoor air quality and often meet criteria for green building certifications like LEED. The long lifespan of these tiles also contributes to resource conservation.

Our High quality Mineral Fiber Ceiling Tiles consistently achieve a Class A fire rating as per ASTM E84 (Standard Test Method for Surface Burning Characteristics of Building Materials). This is the highest classification for building materials, indicating excellent resistance to flame spread and minimal smoke development. This inherent non-combustibility of the mineral fiber board significantly enhances the safety of any building where it is installed.

Many standard mineral fiber board products have good humidity resistance, typically up to 90% RH. For highly humid environments like large bathrooms, kitchens, or indoor pools, we offer specialized High quality Mineral Fiber Ceiling Tiles with enhanced humidity resistance, capable of withstanding up to 99% relative humidity without sagging or warping. It's crucial to select the correct product grade for the specific environmental conditions to ensure longevity and performance.

The most common installation method for mineral fibre suspended ceiling tiles involves a metal suspension grid system. This system consists of main tees, cross tees, and wall angles, creating a framework from which the mineral fiber ceiling tiles are laid in. Different edge types (e.g., square lay-in, tegular, concealed) determine how the tiles sit within or on the grid, influencing the final aesthetic. This method allows for easy access to the plenum for maintenance of utilities.

With proper installation and maintenance, our High quality Mineral Fiber Ceiling Tiles are designed for exceptional durability and a long lifespan, typically lasting 15 to 20 years or more. Factors influencing longevity include the specific product grade, environmental conditions (e.g., humidity levels, temperature fluctuations), and adherence to cleaning guidelines. Our 10-year warranty underscores our confidence in the long-term performance and reliability of our mineral fiber board products.

The Enduring Value of Mineral Fiber Board in Modern Construction

The journey through the world of mineral fiber board reveals a material of extraordinary versatility and performance. From its sophisticated manufacturing process to its critical role in enhancing building safety, comfort, and sustainability, mineral fiber board continues to be an indispensable component in contemporary architecture. As the demand for high-performance, aesthetically pleasing, and environmentally responsible building materials grows, solutions like our High quality Mineral Fiber Ceiling Tiles stand out as prime examples of innovation meeting practical needs.

Whether the priority is superior acoustic control for a bustling office, stringent fire safety for a healthcare facility, or improved energy efficiency for a commercial complex, mineral fiber board consistently delivers. The evolution of mineral fiber ceiling tiles and mineral fibre suspended ceiling tiles continues to push boundaries, offering designers and builders unprecedented flexibility and performance. By choosing a reputable and experienced manufacturer like Xingyuan Ceilings, you are not just acquiring a product; you are investing in a complete solution backed by expertise, proven experience, authoritative certifications, and unwavering trustworthiness. We are committed to providing the best mineral fiber board solutions that contribute to healthier, safer, and more productive built environments for years to come.

References and Further Reading

- The Acoustical Society of America. (n.d.). Acoustics 101: Understanding Sound Absorption. Retrieved from https://acousticalsociety.org/acoustics-101-understanding-sound-absorption/

- ASTM International. (n.d.). ASTM E84 - Standard Test Method for Surface Burning Characteristics of Building Materials. Retrieved from https://www.astm.org/e0084.htm

- Building Green. (2018). Acoustical Ceilings for Healthy Indoor Environments. Retrieved from https://www.buildinggreen.com/blog/acoustical-ceilings-healthy-indoor-environments

- ISO. (n.d.). ISO 9001 - Quality management. Retrieved from https://www.iso.org/iso-9001-quality-management.html

- European Commission. (n.d.). CE Marking. Retrieved from https://single-market-economy.ec.europa.eu/single-market/ce-marking_en

-

Mineral Fiber Ceiling Tiles Embossed Surface PatternNewsAug.05,2025

-

Mineral Fiber Board Xingyuan Vision for Better SpacesNewsAug.05,2025

-

Drop Down Ceiling Tile Office Use FitNewsAug.05,2025

-

PVC Gypsum Ceiling White Base ColorNewsAug.05,2025

-

Access Panel on Ceiling Xingyuan Integrity EthicNewsAug.05,2025

-

Ceiling Trap Doors Fire Resistant DesignNewsAug.05,2025