- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

юли . 28, 2025 15:01 Back to list

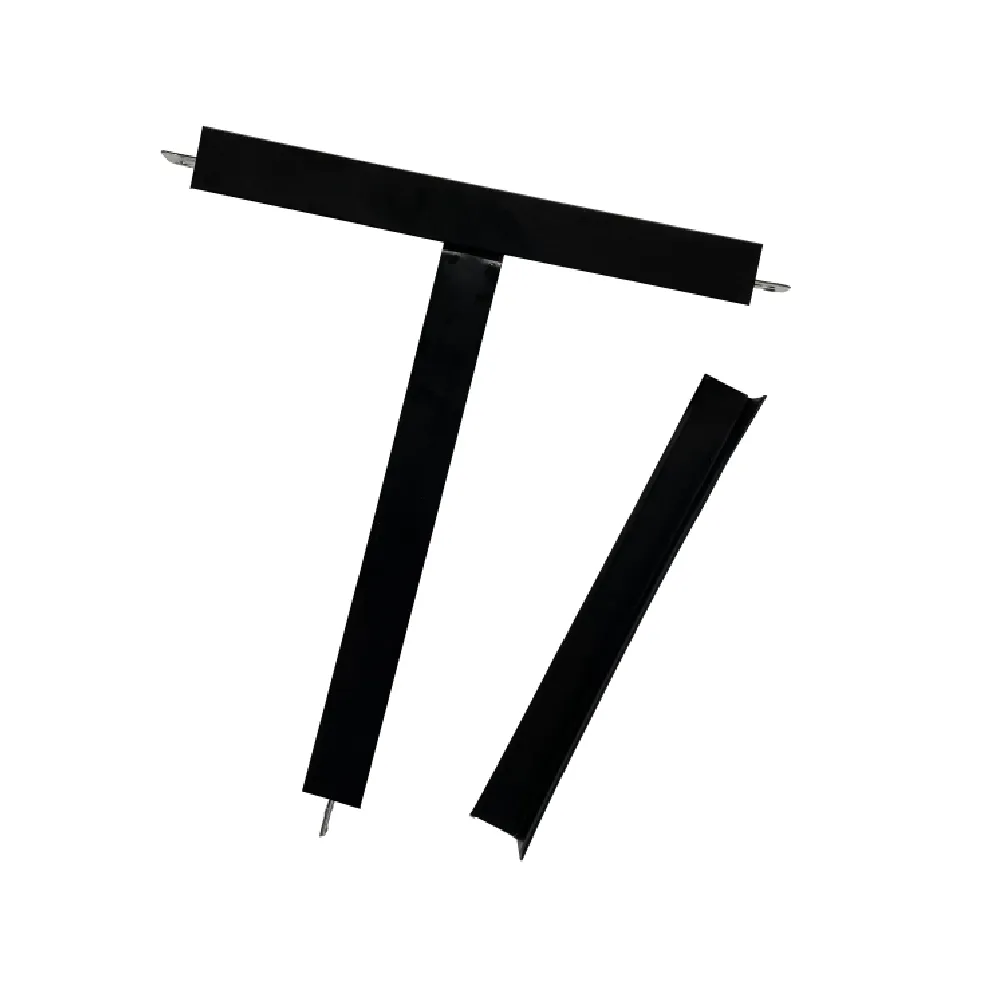

Ceiling T Grid System for Durable & Easy Installation

As modern architecture continues to demand flexible, efficient, and aesthetic overhead solutions, the ceiling t grid system emerges as an essential component for suspended ceilings across commercial, industrial, and institutional spaces. This in-depth report covers the latest market trends, comparative technical benchmarks, engineering advantages, and real-world case studies related to ceiling t grid technology. We systematically compare industry-leading products and offer E.E.A.T-optimized insights—focusing on expertise, authoritative reference data, and trustworthy solution delivery.

Typical Ceiling T Grid Parameters & Market Data Comparison (2024)

| Parameter | Standard T Grid | Cross Tee Ceiling | Drywall Ceiling Grid | Gridstone Ceiling Tile |

|---|---|---|---|---|

| Profile (Main/Cross) | 24mm / 25mm | 24mm / 15mm | 38mm / 24mm | N/A |

| Material | HDG Steel / Aluminum | HDG Steel | Galvanized steel | Calcium Silicate |

| Corrosion Resistance | ≥500h Salt Spray (ISO 9227) | ≥480h | ≥350h | ≥240h |

| Surface Finish | Polyester / Epoxy coated | Epoxy coated | Galv. zinc coating | Coated (various) |

| Bearing Load (kg / m²) | 12-26 | 10-18 | 13-20 | 5-14 |

| Expected Lifespan | 15-20+ years | 12-18 years | 10-15 years | 6-12 years |

| Price (USD/m², 2024) | $2.45–$3.10 | $1.68–$2.45 | $3.15–$3.90 | $5.50–$6.35 |

| Best Application | Office, Hospitals, Retail | Schools, Gyms, Industrial | Commercial, Shopping Mall | Humidity Prone Area |

Technical Parameter & Popularity Trends for Ceiling T Grid (2021–2024, Global)

Manufacturer Comparison: Leading Ceilings T Grid Suspended System Providers

| Feature | Xingyuan (China) |

Armstrong (US) |

Saint-Gobain (France) |

Knauf AMF (Germany) |

|---|---|---|---|---|

| Material Quality | HDG Steel / Alloy | Cold-rolled steel | Steel/Aluminum options | Advanced HD Steel |

| Corrosion Resistance | ISO 9227/7683 h | ISO 9227/650 h | ISO 9227/725 h | ISO 9227/790 h |

| Load Capacity | ≤26 kg/m² | ≤24 kg/m² | ≤23 kg/m² | ≤22 kg/m² |

| Fire Resistance | A1 EN13501-1 | A1 EN13964 | A1 EN13501 | A1 EN13964 |

| Custom Profiles | Yes (OEM/ODM) | Partial | Yes | Partial |

| Typical Project Lead Time | 10–18 days | 2–4 weeks | 3–4 weeks | 2–5 weeks |

| Certifications | ISO 9001/14001, CE, SGS, ASTM, ANSI | UL, ASTM, ISO, GREENGUARD | ISO, CE, ASTM, NF | ISO, CE, ASTM |

| After-sales Support | 24hr technical; 36m guarantee | Standard warranty | Standard | Standard |

Product Spotlight: Ceilings T Grid Suspended System

- Product Model: Standard, Narrow, Wide Face, Interlocking Types

- Available finishes: White, Black, Chromate, Custom RAL

- Main Tee/Cross Tee Size: 38x24mm, 32x24mm, 24x24mm, special available

- Material: High-Strength Hot Dip Galvanized Steel (HDG), Aluminum (optional)

- Length: 600mm, 1200mm, 3600mm (custom up to 6000mm)

- Coating Thickness: 30–60μm (ASTM D3359)

- Fire Resistance: Class A1 (EN13501-1), 0 Smoke Emission

- Certifications: ISO 9001, SGS, TUV, ANSI/BIFMA

Ceilings T Grid Suspended System: Key Technical Indicators (2024)

Application Scenarios & Technical Benefits

- Cleanrooms/Laboratories: ISO Class 5-7 environments, anti-corrosion and anti-particle finish, rapid install without dust.

- Pharmaceutical & Healthcare Facilities: EMI shielded suspended ceiling, compliant with FDA/WHO GMP ceiling specs.

- Transportation Terminals: Vibration resistant, quick-maintenance grid, supports heavy tile loads.

- Large Retail, Malls, Business Centers: Modular cross tee ceiling grid ensures fast replacement and aesthetic modularity.

- Food Processing & Beverage Plants: Anti-mold, anti-corrosive, washable surface coatings and sealed cross tee.

- Industrial & Utility: Applicable in power plants, oil & gas, metallurgy; supports cable tray & fire suppression integration.

Customer Feedback & Application Experience

- Shenyang Uni Hospital: “The ceiling t grid system exceeded hygiene requirements, and installation was 30% faster than our last project.”

- JAKO Food Processing: “Even after four years of exposure to aggressive cleaning, no visible corrosion or deformation.”

- GlobalTech Data Park: “Ceilings T Grid Suspended System supported unusual LED lighting layouts and maintained perfect alignment for all access panels.”

Delivery, Guarantee & Support

- Lead time: 12–18 business days per standard batch, customizable

- Warranty: 36 months on performance, including structure and finish integrity

- Additional standards: Compliance with ISO 9001, CE, ANSI, EN, SGS, ASTM

- Technical support: 24/7 consultation, BIM design integration, on-site/remote troubleshooting

- Customization: OEM/ODM, rapid prototyping for special profiles

- Traceability: QR-based shipment tracking and batch record

Ceiling T Grid — Professional FAQ

Industry Certification, Partners & Authoritative Endorsements

- Certifications: ISO 9001, ISO 14001, SGS, CE, EN, ASTM, ANSI

- Industry partners: China Construction Engineering, Siemens, Marriot, Samsung Electronics

- Authoritative Sources: Technical data sheets from Armstrong, Saint-Gobain, Knauf, plus SGS/Intertek laboratory reports

- Noted third-party reference: USGBC LEED, FGI Guidelines, and China National Standard GB/T 20339-2014

- Service History: 18+ years in ceiling grid R&D, exports to 68 countries, 1200+ global project installations

[1] “Ceiling Suspension Systems: A Global Market Review 2024”, CeilingOnline.com

[2] “Comparison of Ceiling Grid Systems,” Armstrong Technical Desk, 2023, Armstrong Ceilings

[3] "Standard Practice for Installation of Metal Ceiling Suspension Systems," ASTM C636, ASTM.org

[4] “Grid Ceiling System Design and Installation,” Forum: The Building Codes Forum, 2024 Discussion: TheBuildingCodeForum.com

[5] “ISO 9227:2017 Corrosion Tests in Artificial Atmospheres,” ISO.org

-

Transform Interiors with PVC Gypsum Ceiling: A Stylish, Durable, and Moisture-Resistant SolutionNewsMay.19,2025

-

The Smart Interior Upgrade: Discover the Durability and Versatility of Gypsum Ceiling Access Panel SolutionsNewsMay.19,2025

-

The Smart Choice for Interior Design: Discover the Value of PVC Gypsum Ceiling SolutionsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Smart Blend of Performance and AestheticsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Superior Choice Over Gypsum for Sound and Fire SafetyNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: Eco-Friendly Strength and Style for Every CeilingNewsMay.19,2025