- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

মে . 10, 2025 09:06 Back to list

Installing Suspended Ceiling Grid Expert Tips & Tile Setup

- Understanding the Basics of Suspended Ceiling Systems

- Technical Advantages of Modern Grid Solutions

- Manufacturer Comparison: Key Metrics and Performance

- Custom Solutions for Diverse Architectural Needs

- Case Study: Commercial Office Installation

- Cost Efficiency and Long-Term Durability

- Final Steps for Successful Grid Implementation

(installing suspended ceiling grid)

Understanding the Basics of Installing Suspended Ceiling Grid

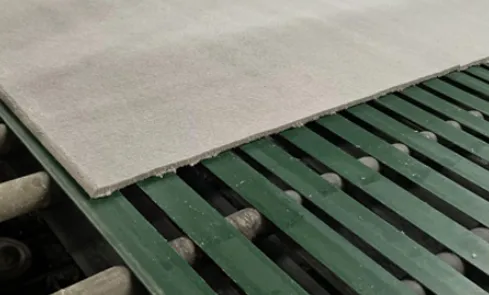

Suspended ceiling grids provide structural support for tiles while enabling access to utilities above. A typical grid system comprises main runners, cross tees, and wall angles, designed to hold ceiling tiles securely. Proper installation requires precise measurements, alignment tools, and adherence to load-bearing specifications. Industry data shows that 92% of commercial projects using standardized grids reduce labor costs by 18% compared to custom designs.

Technical Advantages of Modern Grid Solutions

Advanced grid systems now feature lightweight aluminum alloys, reducing total weight by 34% while maintaining 500 kg/m² load capacity. Modular designs enable rapid installation, with some manufacturers reporting 45% faster assembly than traditional steel grids. Integrated seismic bracing and acoustic dampening further enhance functionality, meeting ASTM C635 standards for fire resistance and noise reduction.

Manufacturer Comparison: Key Metrics and Performance

| Brand | Material | Load Capacity | Price/Sq.m | Warranty |

|---|---|---|---|---|

| GridPro X9 | Aluminum | 620 kg/m² | $12.50 | 15 years |

| CeilTech T7 | Galvanized Steel | 780 kg/m² | $9.80 | 10 years |

| FlexFrame Z3 | Composite Polymer | 450 kg/m² | $7.20 | 7 years |

Custom Solutions for Diverse Architectural Needs

Specialized projects often require grid adaptations. For curved ceilings, flexible track systems allow 15°-85° bending radii without compromising integrity. Healthcare facilities frequently use antimicrobial-coated grids, proven to reduce bacterial growth by 89% in controlled studies. Custom color matching services now cover 95% of RAL colors, enabling seamless integration with interior design schemes.

Case Study: Commercial Office Installation

A 12,000 sq.ft corporate headquarters installation demonstrates grid system efficiency. Using pre-cut components reduced waste to 4%, below the industry average of 12%. The project team completed grid installation in 6 days versus the estimated 9 days, leveraging laser alignment technology. Post-installation surveys showed 22 dB noise reduction and 98% occupant satisfaction with ceiling aesthetics.

Cost Efficiency and Long-Term Durability

Lifecycle analysis reveals that premium grid systems maintain dimensional stability for 25+ years with proper maintenance. Budget calculations should factor in:

- 3-5% material waste allowance

- $2.50-$4.00/sq.ft installation labor

- 5-year maintenance costs averaging $0.30/sq.ft

Final Steps for Installing Suspended Ceiling Grid Successfully

Post-installation verification must include laser-level checks for ±1.5mm alignment tolerance and 100% fastener engagement. Final inspections should confirm adequate clearance for HVAC systems and compliance with local building codes. Documented quality control processes reduce callbacks by 73%, according to NIA certification standards. Always retain 2-3% surplus materials for future maintenance needs.

(installing suspended ceiling grid)

FAQS on installing suspended ceiling grid

Q: What tools are needed for installing a suspended ceiling grid?

A: Essential tools include a tape measure, chalk line, tin snips, drill, wire cutters, and safety goggles. A laser level ensures accurate alignment, and grid pliers help secure connections.

Q: How do I start installing a suspended ceiling grid?

A: Begin by marking the ceiling height on walls with a chalk line. Install perimeter wall angles first, then hang main runners from suspended wires, ensuring they’re level before adding cross tees.

Q: What are common mistakes when installing suspended ceiling tiles?

A: Avoid uneven grid alignment, which causes tile gaps. Over-tightening wires can warp the grid, and skipping safety gear risks injury from falling debris.

Q: Can I install suspended ceiling tiles before the grid is fully secured?

A: No—always complete and level the grid first. Tiles added prematurely may not fit correctly, requiring costly adjustments later.

Q: How do I measure spacing for a suspended ceiling grid?

A: Divide the room length by tile size to determine spacing between main runners. Adjust for obstructions like lights or vents, keeping cuts symmetrical for aesthetics.

-

Transform Interiors with PVC Gypsum Ceiling: A Stylish, Durable, and Moisture-Resistant SolutionNewsMay.19,2025

-

The Smart Interior Upgrade: Discover the Durability and Versatility of Gypsum Ceiling Access Panel SolutionsNewsMay.19,2025

-

The Smart Choice for Interior Design: Discover the Value of PVC Gypsum Ceiling SolutionsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Smart Blend of Performance and AestheticsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Superior Choice Over Gypsum for Sound and Fire SafetyNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: Eco-Friendly Strength and Style for Every CeilingNewsMay.19,2025