- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Ago . 11, 2025 12:00 Back to list

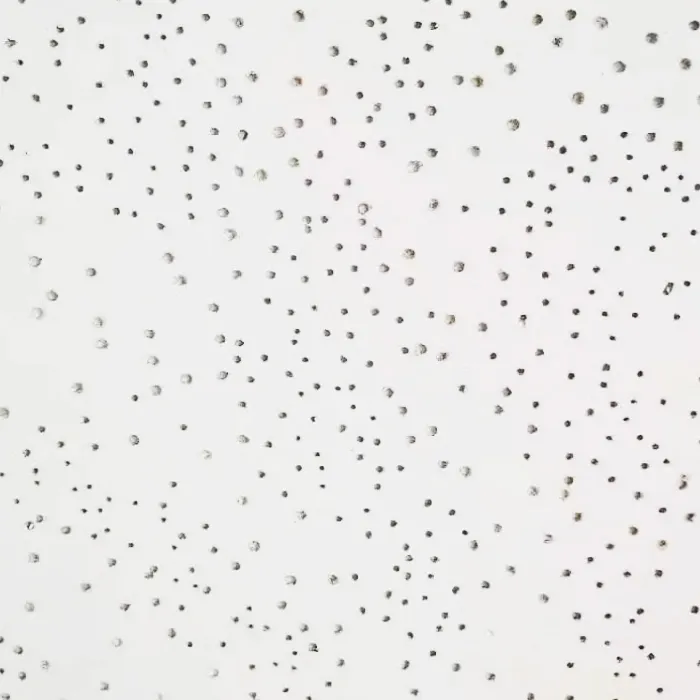

Mineral Fiber Board: Durable Acoustic Ceiling Tiles

Navigating the Landscape of High-Performance Mineral Fiber Ceiling Solutions

In modern commercial and industrial architecture, the demand for building materials that combine aesthetics, functionality, and sustainability is paramount. Among these, mineral fiber board stands out as a critical component, particularly in the form of mineral fiber ceiling tiles. These versatile panels are engineered to meet stringent requirements for acoustic performance, fire safety, thermal insulation, and moisture resistance, making them an indispensable choice for various sectors. The market for mineral fiber false ceiling tiles and mineral fibre suspended ceiling tiles is experiencing steady growth, driven by increasing construction activities worldwide and a growing emphasis on creating healthier, more productive indoor environments. This growth is also fueled by advancements in manufacturing processes, leading to products with enhanced durability and aesthetic appeal, catering to sophisticated design demands in contemporary buildings.

Recent industry trends indicate a strong focus on sustainable and recyclable building materials, with mineral fiber solutions gaining traction due to their inherent eco-friendly properties. Furthermore, the rising awareness about indoor air quality and noise pollution has amplified the need for high-performance ceiling systems that can mitigate these issues effectively. From bustling corporate offices to quiet healthcare facilities, the integration of advanced ceiling solutions is not merely a design choice but a strategic investment in long-term building performance and occupant well-being. Understanding the intricate details of their production, technical specifications, and application benefits is crucial for B2B decision-makers seeking optimal architectural solutions.

The Advanced Manufacturing Process of Mineral Fiber Boards

The production of a high-quality mineral fiber board involves a sophisticated, multi-stage manufacturing process designed to imbue the final product with superior performance characteristics. This begins with the careful selection of raw materials, primarily slag wool or stone wool, which are inert, non-combustible, and possess excellent thermal and acoustic properties. These fibers are typically combined with a binder, often starch-based, and other additives to enhance specific attributes such as sag resistance, moisture resistance, and fire retardancy. The manufacturing process typically follows a wet-felting or molding technique.

The general manufacturing workflow can be outlined as follows: First, raw mineral fibers are blended and refined to achieve a consistent pulp. This pulp is then fed into a forming machine, which uses a wet-laid process to create a continuous mat of fiber. This mat is then subjected to high-temperature curing in ovens, where the binders polymerize, solidifying the structure and giving the mineral fiber board its final shape and rigidity. After curing, the material undergoes precision cutting to specified dimensions and edge finishes, such as square edge, tegular, or concealed grid options, ensuring a seamless fit for various ceiling systems.

Throughout this process, stringent quality control measures are implemented. Products are rigorously tested against international standards such as ISO 9001 for quality management and ASTM E84 for surface burning characteristics. This ensures that each mineral fiber board, whether destined for an office or a healthcare facility, meets defined benchmarks for fire resistance, noise reduction coefficient (NRC), ceiling attenuation class (CAC), thermal conductivity, and sag resistance. The typical lifespan of these boards can extend beyond 20 years, making them a durable choice for applicable industries ranging from commercial and educational institutions to healthcare, retail, and light industrial facilities, where their superior acoustic and fire safety features offer significant advantages in energy efficiency and building safety.

Key Technical Specifications of High-Quality Mineral Fiber Ceiling Tiles

Understanding the technical parameters of mineral fiber board is crucial for specifiers and engineers to select the appropriate product for a given application. These parameters directly influence performance in areas such as acoustics, fire safety, and thermal regulation. The table below provides a comprehensive overview of typical specifications for high-quality mineral fiber ceiling tiles, based on common industry standards and product offerings. These metrics are critical for ensuring compliance with building codes and achieving desired indoor environmental quality.

| Parameter | Typical Range/Value | Standard/Test Method | Benefit to Application |

|---|---|---|---|

| Material Composition | Mineral wool, perlite, clay, starch binders | Proprietary blends | Durability, acoustic performance, fire resistance |

| Noise Reduction Coefficient (NRC) | 0.50 - 0.90 | ASTM C423 | Excellent sound absorption for quiet environments |

| Ceiling Attenuation Class (CAC) | 30 - 45 | ASTM E1414 | Reduces sound transmission between adjacent rooms |

| Fire Resistance Rating | Class A (Flame Spread & Smoke Developed) | ASTM E84 | Enhanced safety, limits flame spread |

| Thermal Conductivity (k-value) | 0.040 - 0.055 W/(m·K) | ASTM C518 | Improved energy efficiency, reduced heating/cooling costs |

| Light Reflectance (LR) | 0.80 - 0.90 | ASTM E1477 | Maximizes natural light, reduces need for artificial lighting |

| Humidity Resistance (RH) | Up to 95% at 40°C | ASTM C1396 / C1186 | Prevents sag in high-humidity environments |

| Standard Dimensions | 600x600mm, 600x1200mm (various thicknesses) | Industry Standard | Versatile for different grid systems |

These specifications allow architects and contractors to precisely tailor their ceiling solutions to specific project needs, whether the priority is noise control in a busy call center, fire protection in a public building, or energy efficiency in an large industrial complex. The balance of these properties defines the overall quality and suitability of mineral fiber ceiling tiles for a given application.

Diverse Application Scenarios and Distinct Advantages

The versatility and robust performance of mineral fiber board make it an ideal choice for a vast array of commercial, institutional, and industrial environments. Its primary strengths lie in enhancing indoor acoustics, providing superior fire protection, and contributing to better thermal insulation, alongside aesthetic flexibility.

Acoustic Excellence:

In offices, educational facilities, and healthcare settings, controlling ambient noise is crucial for productivity, learning, and patient recovery. Mineral fiber suspended ceiling tiles excel at sound absorption (high NRC values) and sound attenuation (high CAC values), effectively reducing reverberation and limiting sound transmission between rooms. This creates quieter, more comfortable environments, promoting focus and privacy. For instance, a typical call center can significantly improve speech intelligibility and reduce stress levels among employees by utilizing high-NRC mineral fiber board.

Uncompromised Fire Safety:

Given their non-combustible mineral composition, these tiles offer exceptional fire resistance. They are typically rated as Class A materials, meaning they have minimal flame spread and smoke development in a fire event. This is particularly vital in public buildings, corridors, and emergency exits, where fire safety regulations are stringent. The ability of mineral fiber ceiling tiles to form a fire barrier helps contain fires, allowing occupants more time to evacuate safely and minimizing structural damage. This critical safety feature cannot be overstated for any commercial or public building.

Thermal Performance and Energy Efficiency:

Beyond acoustics and fire protection, mineral fiber false ceiling tiles contribute significantly to a building's thermal envelope. Their inherent thermal insulation properties help to reduce heat transfer through the ceiling, leading to more stable indoor temperatures and lower energy consumption for heating and cooling. This translates into tangible operational cost savings over the lifespan of the building, making them a sustainable choice for environmentally conscious projects. In large spaces like warehouses or manufacturing plants, optimizing thermal insulation can lead to substantial energy savings, reducing overall operational costs.

Selecting the Right Partner: Manufacturer Comparison and Custom Solutions

Choosing the right supplier for mineral fiber ceiling tiles is a critical decision for any B2B buyer. It goes beyond mere product specifications to encompass reliability, service, and the ability to provide tailored solutions. When evaluating manufacturers, consider their adherence to international quality standards, their research and development capabilities, and their track record of successful project delivery. A reputable manufacturer will possess certifications like ISO 9001, demonstrating their commitment to consistent quality management systems.

Manufacturers like Xingyuan Ceilings specialize in high-quality mineral fiber board, offering a comprehensive range of products designed to meet diverse architectural and functional requirements. Key differentiators include the breadth of their product portfolio, offering various textures, patterns, and edge details (e.g., square, tegular, shiplap) to match specific design aesthetics and installation methods. Furthermore, the ability to provide customized solutions, whether it's a unique dimension, a specific performance metric, or a proprietary finish, is invaluable for projects with distinct needs. For example, a project requiring an exceptionally high NRC for a recording studio might need a custom-engineered panel.

Beyond the product itself, evaluate a manufacturer's technical support, lead times, and warranty policies. A strong technical team can provide invaluable assistance with specifications, installation guidance, and troubleshooting. Reliable delivery schedules are paramount for project timelines, while comprehensive warranties provide assurance of product longevity and performance. Xingyuan Ceilings prides itself on its service excellence, offering rapid response times and expert advice to ensure seamless project execution from initial consultation to final installation, fostering trust through consistent quality and dedicated customer support, a commitment reflected in our extensive service history.

Case Studies & Trustworthiness: Real-World Applications and Support

The true measure of a product's performance and a manufacturer's reliability lies in its real-world application and the support provided. Our mineral fiber board products have been successfully implemented in numerous prestigious projects globally, showcasing their durability and performance under diverse conditions.

Application Case: Corporate Headquarters Acoustic Upgrade

A leading technology firm's new corporate headquarters required a ceiling system that could provide superior acoustic comfort in open-plan offices while maintaining a sleek, modern aesthetic. Our high-NRC mineral fiber false ceiling tiles were chosen for their exceptional sound-absorbing capabilities (NRC 0.85) and their seamless integration with the building's contemporary design. The project resulted in a significant reduction in ambient noise levels, leading to improved employee concentration and satisfaction, as confirmed by post-occupancy evaluations.

Ensuring Trust and Reliability:

Our commitment to quality extends beyond product manufacturing. We uphold the highest standards of trustworthiness through transparent processes and robust customer support. All our mineral fiber suspended ceiling tiles undergo rigorous third-party testing to ensure compliance with international standards, providing verifiable data sheets and certifications (e.g., CE, ASTM).

Frequently Asked Questions (FAQ):

- Q: What is the typical delivery period for bulk orders?

A: Standard delivery for bulk orders typically ranges from 2-4 weeks, depending on the volume and customization requirements. Expedited shipping options are available upon request. - Q: What warranty is provided with your mineral fiber ceiling tiles?

A: We offer a comprehensive 10-year limited warranty against manufacturing defects and sag resistance under specified conditions, ensuring long-term performance and peace of mind. - Q: How do you ensure product consistency and quality control?

A: Our manufacturing facilities adhere strictly to ISO 9001 quality management systems. Each batch undergoes multi-point inspections, from raw material verification to final product performance testing (e.g., acoustic, fire, dimensional stability) to guarantee consistency. - Q: Can you provide technical support for installation?

A: Yes, our dedicated technical support team is available to provide detailed installation guides, best practice recommendations, and on-site assistance for large-scale projects, ensuring optimal performance of your ceiling system.

References

- American Society for Testing and Materials (ASTM) International. "Standard Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method." ASTM C423.

- International Organization for Standardization (ISO). "Quality management systems – Requirements." ISO 9001.

- National Fire Protection Association (NFPA). "NFPA 13: Standard for the Installation of Sprinkler Systems."

- United States Environmental Protection Agency (EPA). "Indoor Air Quality (IAQ) Standards."

- Acoustical Society of America (ASA). "Acoustical Performance Criteria, Design Requirements, and Guidelines for Schools." ANSI/ASA S12.60-2010.

-

Mineral Fiber Ceiling Tiles Embossed Surface PatternNewsAug.05,2025

-

Mineral Fiber Board Xingyuan Vision for Better SpacesNewsAug.05,2025

-

Drop Down Ceiling Tile Office Use FitNewsAug.05,2025

-

PVC Gypsum Ceiling White Base ColorNewsAug.05,2025

-

Access Panel on Ceiling Xingyuan Integrity EthicNewsAug.05,2025

-

Ceiling Trap Doors Fire Resistant DesignNewsAug.05,2025