grid ceiling tiles sizes

-

...

...

Links

One of the key factors contributing to the popularity of flat leather drive belts is their relatively low maintenance requirements compared to other types of belts. With proper care, leather belts can last for many years, providing an economical solution for businesses. Regular maintenance practices include periodic inspections for signs of wear, lubrication to reduce friction, and conditioning treatments to keep the leather supple. Unlike synthetic materials, leather has a natural resilience, allowing it to withstand the rigors of daily use without failing prematurely.

5. Visual Inspection If you can access the timing belt, look for cracks, fraying, or other signs of wear.

As correias dentadas, também conhecidas como correias sincronizadoras, são componentes fundamentais em diversos mecanismos, especialmente em motores de combustão interna e equipamentos industriais. Elas são projetadas para transferir movimento de um componente para outro de forma precisa, garantindo que o tempo de funcionamento de um mecanismo seja mantido. Neste artigo, vamos explorar os principais tipos de correias dentadas, suas características e aplicações.

A timing belt pulley is a cylindrical component designed to transfer rotational motion from one part of a machinery system to another. The pulley itself typically features grooves that match the teeth of a timing belt. This design helps prevent slippage, ensuring that the rotational motion is conveyed with high precision. Timing belt pulleys are usually made from durable materials like aluminum, steel, or reinforced plastic, capable of withstanding the stresses of high-speed operations.

One of the most notable features of J section Poly V belts is their flexibility. The multiple ribs allow the belt to bend around small diameter pulleys, which is critical in many automotive applications where space is at a premium. This flexibility also helps to minimize vibration and noise, leading to a smoother operation and increased lifespan for both the belt and the components it interacts with.

Styling a PJ Belt can be both fun and rewarding. The primary usage is, of course, with pajamas; however, this accessory proves its versatility when paired with various outfits. For instance, a PJ Belt can elevate a cozy oversized t-shirt and joggers by adding a touch of sophistication. This trend encourages mixing and matching while keeping comfort at the forefront.

2. Width and Length Measure the appropriate width and length needed for your application. Flat drive belts come in various sizes, so it’s crucial to choose one that fits your machinery correctly.

The material of your motorcycle belt can greatly impact its performance and longevity. Here are some common materials used in manufacturing motorcycle belts

To ensure optimal performance and longevity of flat V belts, regular maintenance is important. This includes checking for signs of wear, such as fraying or cracks, and ensuring proper tension and alignment during installation. Operators should regularly inspect pulleys to ensure they are not damaged and that the surfaces are clean, as dirt and debris can lead to slippage and reduced efficiency.

2. V-Belts These belts have a trapezoidal cross-section, which allows them to fit snugly into corresponding grooves on pulleys. V-belts are more efficient in power transmission compared to flat belts, as they have a larger surface area in contact with the pulley, reducing the chances of slippage. They are commonly used in modern lathes and are favored for their durability and ability to handle heavy loads.

2. Reduced Noise Unlike chains, which can create significant noise while operating, timing belts operate quietly, making them ideal for applications where noise reduction is a factor.

3. Adaptability As their name implies, universal V-belts can fit a wide array of applications, making them a practical choice for industries that require flexibility in their machinery setups.

3. Oil Leaks If you see engine oil pooling near the timing belt cover, it could mean that the timing belt seal is worn.

To ensure that the drive belt remains in good condition, regular inspection is crucial. Mechanics typically recommend checking the drive belt every 30,000 miles or so, although this may vary depending on the vehicle's make and model. During inspections, it is wise to look for signs of wear and looseness. Replacing a worn drive belt before it fails can save car owners from expensive repairs and inconveniences.

Maintenance Tips

Regular maintenance of V belts is crucial for the overall health of your vehicle. Here are a few tips to ensure their longevity

Conclusion

In conclusion, the dynamometer belt is much more than a simple accessory in automotive testing; it's a pivotal component that aids engineers in optimizing vehicle performance and ensuring compliance with industry standards. Understanding the significance of quality, the various factors influencing pricing, and the range of options available is essential for anyone involved in automotive engineering. As the automotive industry continues to evolve, the demand for high-quality dynamometer belts will likely increase, reflecting the broader pursuit of performance excellence in vehicles. By investing wisely in these components, automotive professionals can drive innovation, safety, and efficiency forward in their operations.

1. Material Quality The composition of the drive belt is one of the primary factors affecting its price. Most belts are made of rubber or a rubber composite blended with other materials for enhanced durability and flexibility. High-quality belts utilize materials designed to withstand extreme conditions, ensuring longevity and reducing the need for frequent replacements. Consequently, premium belts come at a higher price but offer better performance and reliability.

The versatility of multiribbed belts makes them an ideal choice for a variety of mechanical systems where space and efficiency are critical.

1. Regular Inspections Include timing belt inspections in your regular vehicle maintenance routine. Look for any visible signs of wear, and consult a mechanic if you have any concerns.

4. Modular Tooth Timing Belts These belts use a modular design that allows for easy replacement of individual sections, making them ideal for applications where time and accessibility are critical.

For those unfamiliar with selecting the right V-belt size, measuring the length of an existing belt can be beneficial. When measuring, follow these steps

Exploring the Versatility of Flat Belt Rubber in Modern Industries

Understanding Flat Timing Belts Importance, Maintenance, and Benefits

I takt med at vi ser fremad, er potentialet for 6PK1138 ubegribelig. Med sin kombination af brugervenlighed, sikkerhed, tilpasningsevne og bæredygtighed repræsenterer det en ny æra inden for teknologisk innovation. 6PK1138 har potentiale til at ændre måden, vi interagerer med vores hjem, arbejdspladser og endda med hinanden.

4. Heavy-Duty Poly V Belts Heavy-duty Poly V belts are designed to handle rigorous operational conditions. They are thicker and stronger than standard belts, making them suitable for applications involving heavy loads and prolonged use. These belts are commonly found in construction equipment, mining machinery, and other heavy-duty industrial applications.

A timing belt is a reinforced rubber belt with teeth that fit into the grooves of the engine's camshaft and crankshaft gears. Unlike traditional serpentine belts that need to drive multiple accessories, the timing belt is a dedicated component responsible solely for maintaining the timing of the engine’s operation. A well-functioning timing belt is crucial for ensuring optimal engine performance and efficiency.

1. Safety First Before working on any machinery, ensure that it is turned off and disconnected from its power source. This includes unplugging electric tools or turning off gas-powered equipment.

Πότε Πρέπει να Αλλάξετε τον Ζωνοδέτη;

On average, the cost of a drive belt can range from $20 to $100, depending on the factors mentioned above. Serpentine belts typically range between $25 and $75, while timing belts can cost anywhere from $50 to $150, often excluding installation costs. Industrial drive belts can vary widely based on specifications and sizes, with prices that can soar into the hundreds of dollars.

Choosing the Right PK Belt

Despite their advantages, timing belts have a limited lifespan and are subject to wear and tear due to heat, friction, and engine vibrations. Most manufacturers recommend replacing the timing belt every 60,000 to 100,000 miles, depending on the vehicle's make and model. Ignoring this recommendation can lead to catastrophic engine failure, especially in interference engines, where the pistons and valves occupy the same space in the engine block. If the timing belt breaks, the pistons may strike the open valves, resulting in severe engine damage and costly repairs.

ينصح معظم المصنعين بتغيير حزام التوقيت كل 60,000 إلى 100,000 ميل، ولكن يجب دائمًا مراجعة دليل المستخدم الخاص بالسيارة للحصول على توصيات دقيقة. يمكن أن تؤدي الإشارات المبكرة مثل الضوضاء الغريبة أو الاهتزازات غير العادية إلى أن الحزام بحاجة إلى فحص.

Recognizing the signs of a failing belt can save you time, money, and trouble. For serpentine belts, you might notice

As the engine cranks, the rotational energy is transmitted through the PK belt to the alternator pulley. This rotation causes the rotor inside the alternator to spin, inducing a magnetic field. According to Faraday’s law of electromagnetic induction, this spinning magnetic field generates electrical current in the stator windings of the alternator. The result is an output of alternating current (AC), which is then converted into direct current (DC) through a built-in rectifier. This DC power is what charges the vehicle’s battery and powers the electrical systems.

Signs of Wear and Tear

Factors Affecting Timing Belt Rubber Durability

Additionally, the agricultural sector employs Synchroflex timing belts in machinery such as harvesters and planting equipment, where precision and reliability are crucial for productivity. Their versatility also extends to home appliances, like washing machines, where they contribute to the silent and smooth operation of the motor.

2. Reduced Slippage The multiple ribs of the belt enhance grip, minimizing slippage during operation. This results in improved performance and ensures that power is transmitted effectively between components.

3. Tension Adjustment After installing the new belt, adjust the tension using the tensioner to allow proper function and prevent slippage.

Like any other mechanical component, the alternator drive belt can wear out over time. Recognizing the signs of wear is crucial to prevent more severe problems. Here are some common indicators

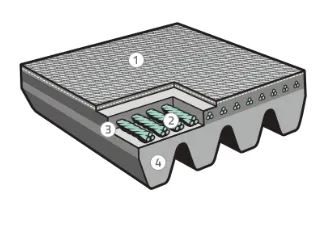

The construction of a V ribbed belt typically involves several layers. The outer layer is made of rubber or synthetic materials that offer durability and resistance to wear, weather, and extreme temperatures. Beneath this outer layer lies a series of functional ribs, which are responsible for ensuring maximum contact with the pulleys. The ribs provide greater surface area than traditional V-belts, which results in better grip and reduced slippage.

To prolong the life of your motorcycle belt, consider these maintenance tips

Understanding the Costs of Car Seat Belts An Essential Component of Vehicle Safety

Advantages of Variable Speed Belts

What is a Timing Belt?