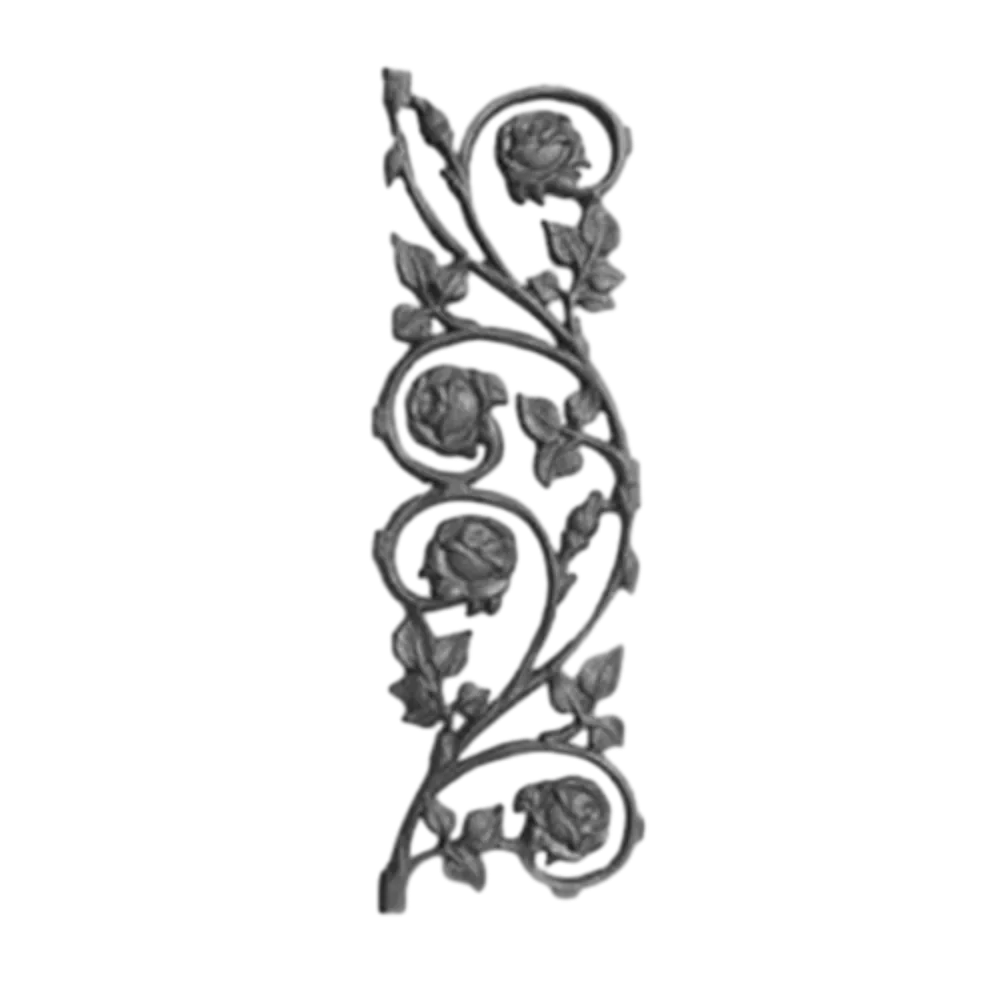

As we embrace the beauty of okrasná liatina, the importance of preservation and restoration becomes paramount. Many historic structures adorned with decorative cast iron are at risk due to neglect, weathering, and urban development. Efforts to preserve these elements not only protect cultural landmarks but also maintain a connection to history. Restoration projects require skilled artisans who understand the techniques and intricacies of working with cast iron, ensuring that the original artistry is respected and maintained.

3. Rubber Wheels Rubber wheels are an excellent choice for sliding doors that require quiet operation. They provide a cushioned glide and are gentle on the track, reducing wear. However, rubber may degrade faster compared to harder materials, especially when exposed to UV rays or extreme temperatures.

Eco-Friendliness

4. Gates

wrought fence parts

aluminium sliding door rollers. The rollers should be able to support the weight of the door without sagging or becoming misaligned. It's also a good idea to choose rollers with a high load capacity to ensure that they can handle the demands of heavy doors.

aluminium sliding door rollers. The rollers should be able to support the weight of the door without sagging or becoming misaligned. It's also a good idea to choose rollers with a high load capacity to ensure that they can handle the demands of heavy doors. There is a current trend where the most fashionable thing in construction, both residential and office, is large glazing. Interestingly, the best material for such large windows is aluminium. Thanks to aluminium, architects and investors alike can let their imagination run wild and design huge windows in rooms, often even covering an entire wall! What’s more, aluminium blends in perfectly with simple yet modern shapes, making it a fashionable element in the construction industry.

Aluminum louver profiles for windows

Common Applications

Bottom hung windows opening inwards

door track rollers. The weight and size of the door will determine the type of rollers needed to support the door and ensure smooth operation. It is also important to choose rollers made from high-quality materials that can withstand frequent use and provide long-lasting durability.

Some feature a brushed finish for a subtle, understated look, while othersa polished sheen that adds a touch of glamor Some feature a brushed finish for a subtle, understated look, while othersa polished sheen that adds a touch of glamor

Some feature a brushed finish for a subtle, understated look, while othersa polished sheen that adds a touch of glamor Some feature a brushed finish for a subtle, understated look, while othersa polished sheen that adds a touch of glamor stainless steel door pulls. There are also options with integrated locks, offering both style and security.

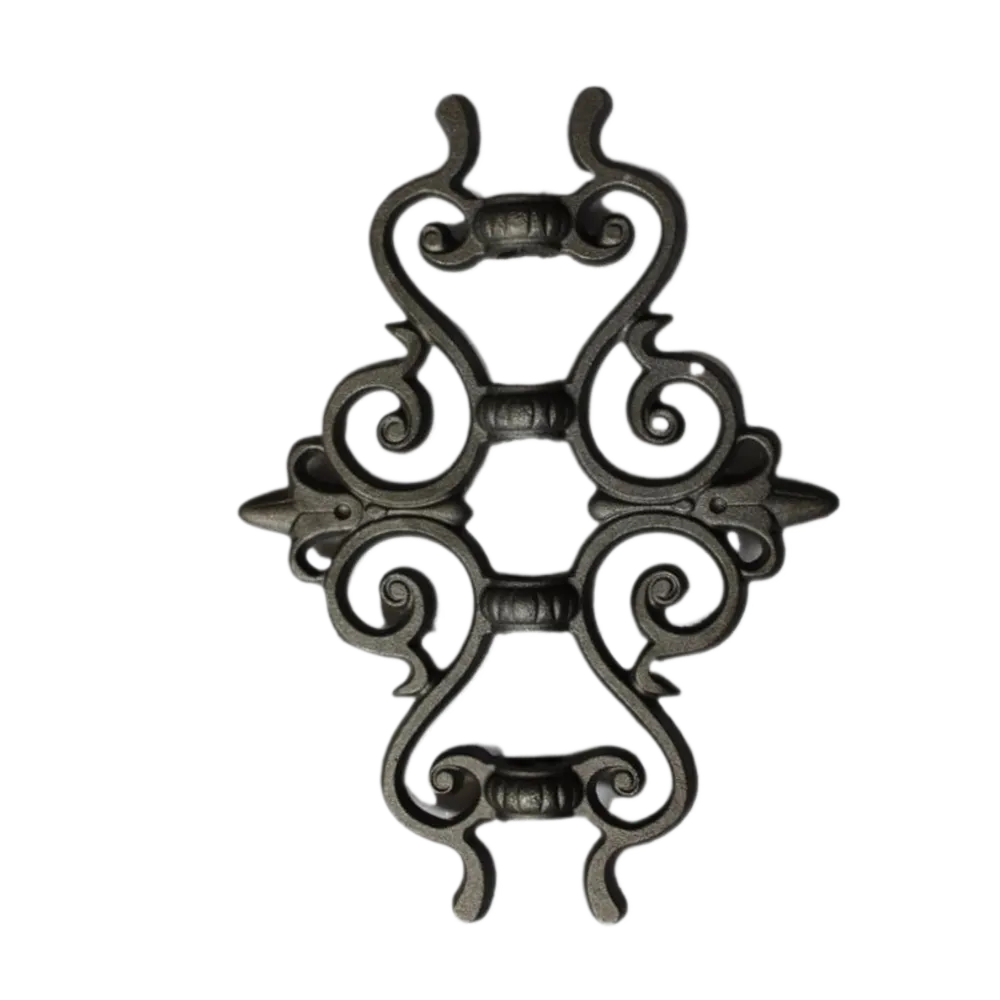

stainless steel door pulls. There are also options with integrated locks, offering both style and security.  cast iron ornament. Unlike many other materials used in decorative arts, iron is resistant to corrosion and can withstand the elements, making it suitable for both indoor and outdoor use. This longevity ensures that these ornaments can be enjoyed for generations, often becoming cherished family heirlooms.

cast iron ornament. Unlike many other materials used in decorative arts, iron is resistant to corrosion and can withstand the elements, making it suitable for both indoor and outdoor use. This longevity ensures that these ornaments can be enjoyed for generations, often becoming cherished family heirlooms.

Furthermore, wrought iron components can be painted or coated with different materials to enhance their appearance and protect them from damage Furthermore, wrought iron components can be painted or coated with different materials to enhance their appearance and protect them from damage

Furthermore, wrought iron components can be painted or coated with different materials to enhance their appearance and protect them from damage Furthermore, wrought iron components can be painted or coated with different materials to enhance their appearance and protect them from damage wrought iron components.

wrought iron components.

Aluminum ornamental iron fencing is becoming the most popular type of fencing especially for residential fencing. Cost is definitely the driving force because aluminum fencing can be manufactured in large quantities at a faster production rate and at a lower cost of production. Aluminum fencing is produced through an extrusion process that basically pushes aluminum blocks of materials through a die system that adheres to the contour of that particular die. Once the piece is formed, the components of the different style of ornamental fencing goes through several steps of priming and powder coating, boxed and ready for shipment from the manufactures to different distributors located throughout the U.S.