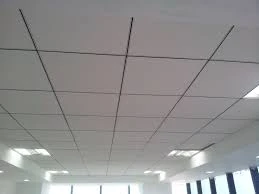

ceilingmax mount grid kit 100 sq ft

Links

If you follow the above instructions, the oil seals should work properly. Also watch the video below for an example of the installation process.

High Mileage Motor Oil

6 GUIDELINES TO FOLLOW WHEN CHOOSING AN OIL SEAL

A patent for an oil seal was filed by Nelson Thomas Edward on August 12, 1937, and published a year later. There were two purposes described. The device was to provide an oil seal between a fixed housing and a rotating part. The seal is described as

What is Oil Seal

3. Fluid types: Oil seals interact with oils, fuels, grease, water, and more. Choosing a seal material that is most compatible with your chosen medium can help to increase the durability of the seal and its internal components.

Valve cover gaskets and head gaskets are essential components in automotive engines, serving distinct yet crucial roles in maintaining the integrity and functionality of the engine. The valve cover gasket seals the junction between the valve cover and the cylinder head, preventing oil leaks and contaminants from entering the engine. On the other hand, the head gasket seals the cylinder head to the engine block, ensuring the containment of combustion gases and the separation of oil and coolant passages.

Despite being incredibly flexible, silicone has some significant drawbacks. The toughness, resistance to wear, and abrasion of many silicone compounds are poor. If you seriously need an oil seal material with better strength and resistance to high temperature, the perfect option is Viton.

Synthetic Blend Motor Oil

The oil seal is our first line of defense in regards to keeping lubrication inside the reducer. It might also be described as the last line of defense – keeping contaminants outside the reducer where they belong. The average seal is incredibly simple in design – made up of a case, a lip or lips, and frequently a garter spring. Of course, some are exponentially more intricate and are manufactured with unusual materials, but the majority are straightforward.

Conclusion

Oil Seals – Everything You Need To Know About

This technique is used when the seal depth must match the housing surface precisely. It involves stopping the installation tool at the machined housing face. Ensure the tool is perfectly perpendicular to the shaft for best results. This technique is ideal for applications requiring exact seal positioning relative to the housing face.

Also, sealant should never be used on the housing and the installation guidelines, as discussed earlier, should be followed.