hatch in ceiling

-

...

...

Links

- Regular Inspections Routinely check for signs of wear on the V-belt, such as cracking, fraying, or glazing, which can affect performance.

3. Clean Environment Keep the area around the belt clean and free of debris. Contaminants can adversely affect the belt's performance and lead to premature failure.

Proper maintenance is essential to maximize the lifespan and performance of raw edge cogged V-belts. Here are some key practices to consider

DIY Replacement vs. Professional Help

Understanding V-Belt Clutches A Comprehensive Overview

- Industrial Machinery These belts are widely used in conveyor systems, robotics, and automation equipment, where reliability and performance are essential. Their high load capacity and low friction characteristics are critical for minimizing downtime and maintenance.

Automatic belts also minimize wardrobe malfunctions. Traditional belts can often become loose throughout the day, leading to discomfort or even embarrassment. Automatic belts ensure a consistently perfect fit, allowing wearers to feel confident and secure in their appearance.

The 6PK 2140/6PK belt is commonly utilized in automotive applications, especially in driving components such as alternators, water pumps, power steering pumps, and air conditioning compressors. In modern vehicles, where multiple systems must operate seamlessly together, the reliability of these belts is crucial to ensure optimal performance and efficiency.

The aesthetics of a belt flat not only contribute to a fashionable outfit but also serve practical purposes. For example, wearing a thin and flat belt can help to cinch the waist of a dress or high-waisted pants, creating a cohesive look without adding unnecessary bulk. This is particularly appealing for evening wear or fitted clothing where the goal is to enhance one's silhouette without distractions.

Conclusion

Mitsuboshi A Legacy of Innovation

- Consumer Electronics In devices such as printers, 3D printers, and scanners, small toothed belts facilitate the precise movement of print heads and other mobile components, enhancing print quality and operational speed.

- Environmental Considerations V-belts can degrade from exposure to oil, dirt, and extreme temperatures. It’s essential to keep the engine compartment clean and protected from harmful substances.

The choice between flat and V-belt drives often depends on the specific needs of the application at hand. Flat belt drives are more commonly used in environments requiring long-distance power transmission at moderate capacities. They can be found in industries such as food processing, agriculture, and textile production.

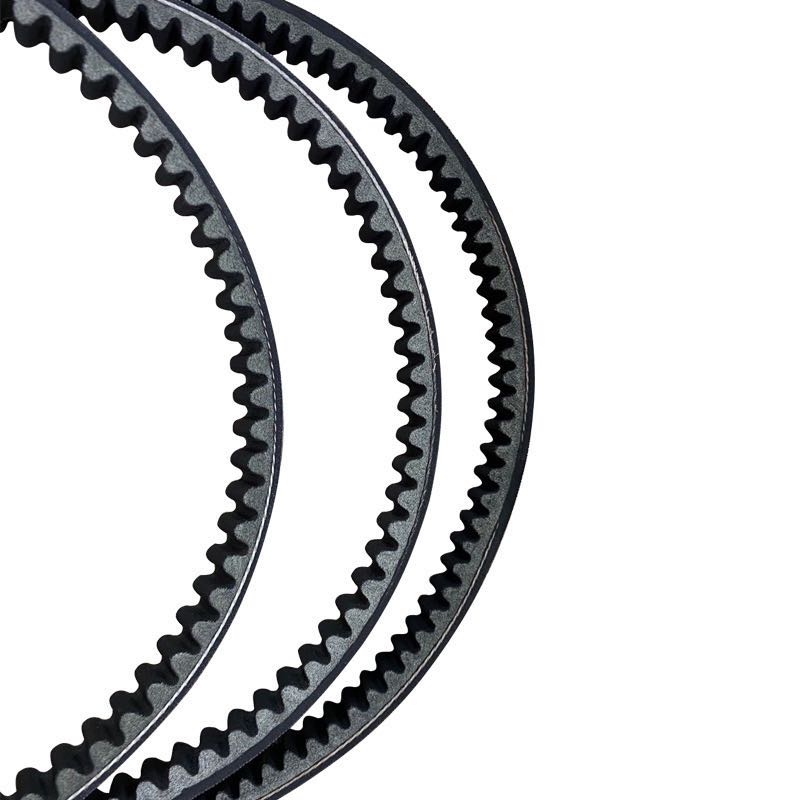

1. Increased Flexibility The cogged design enables these belts to bend more easily around pulleys, making them suitable for applications where space is limited and efficiency is crucial.

- Alignment Misalignment can cause uneven wear and excessive noise, so it’s essential to maintain proper alignment between the belt and pulleys.

5. Temperature Management Monitor operating temperatures, as excessive heat can damage the belt material over time. Ensure proper cooling mechanisms are in place, particularly in automotive applications.

When it comes to auto parts, quality is paramount. Poor-quality components can lead to vehicle malfunction, safety hazards, and ultimately higher repair costs. Volvo vehicles are renowned for their safety, performance, and reliability. Hence, sourcing high-quality auto parts is crucial for maintaining these attributes. Yiwu’s suppliers often provide a blend of original equipment manufacturer (OEM) parts and aftermarket alternatives, offering a variety of options for buyers. OEM parts are manufactured to meet Volvo's exact specifications, ensuring a perfect fit and performance. On the other hand, aftermarket parts can offer significant savings, often without sacrificing quality.

Understanding V-Belts The Essential Component in Mechanical Systems

The Function of the Alternator Fan Belt

Components of the Machine

Timing belts come in various types, including trapezoidal, round, and tooth profiles. The choice of the belt type will depend on the application’s requirements. For example, trapezoidal belts are commonly used in automotive engines due to their high efficiency in power transmission and ability to operate at high speeds.

Signs of Timing Belt Wear

Flat belts must possess certain physical and chemical properties to ensure efficient operation. These include

Ribbed drive belts have revolutionized power transmission in many fields, combining efficiency, durability, and versatility. Their unique design allows for effective power transfer in a compact form, making them ideal for modern automotive and industrial applications. As technology continues to advance, the demand for ribbed drive belts is likely to grow, leading to ongoing innovations in material science and engineering design. With their myriad of benefits, ribbed drive belts will remain a fundamental component in the machinery that powers our everyday lives.

In manufacturing, J section Poly V belts are used in conveyor systems, textile machinery, and robotics. Their ability to handle heavy loads while maintaining a small footprint makes them ideal for applications where efficiency and space savings are paramount.

Conclusion

Signs of a Failing Timing Belt

Maintenance and Longevity

The electrical system of the Daihatsu Terios encompasses various parts, including the alternator, starter motor, battery, and fuses. These components are essential for starting the vehicle and powering various electrical accessories, such as headlights, infotainment systems, and climate control. Regular checks of the battery terminals and electrical connections can prevent starting issues and ensure that all systems function smoothly.

Characteristics of Poly Flat Belts

Flat leather belts are crafted from natural leather, often derived from cows, which undergoes a tanning process to enhance its durability and resistance to wear. The belts are typically flat, which allows them to sit closely against pulleys and other mechanically driven components. This design ensures optimal friction and power transmission efficiency. Additionally, flat leather belts are available in various widths and thicknesses, making them adaptable to different machinery needs and specifications.

Common Issues and Maintenance

4. Belt Profile

2. Cost-Effectiveness The availability of standard sizes and materials means that the 15mm open timing belt can often be sourced at lower costs compared to custom or specialized belts.

Poly V belt pulleys, a crucial component in various mechanical systems, are designed to work with poly V belts, also known as multi-ribbed belts. These pulleys are engineered to transfer power efficiently while providing a quieter and smoother operation compared to traditional V-belts. As the demand for high-performance and compact designs in automotive and industrial applications increases, understanding the functionality and advantages of poly V belt pulleys becomes essential.

Understanding the Importance of Belts for Pulleys

3. Home Appliances Found in various devices, such as washing machines and lawn equipment, where reliability and durability are essential.

A dynamometer belt is a specialized rubber or synthetic belt used to transfer power from the engine to the dynamometer for testing purposes. The belt connects the vehicle’s drivetrain to the testing apparatus, enabling engineers and technicians to accurately measure the engine's specifications under controlled conditions. Its design and material quality are crucial, as they must withstand high tensions and variable environmental factors during testing.

In addition to their benefits in fitness, abdominal belts can also play a crucial role in improving posture. Many individuals, especially those who sit for long periods at their jobs, struggle with poor posture. Wearing an abdominal belt can serve as a physical reminder to sit up straight and engage the core muscles. Improved posture not only enhances appearance but also reduces the risk of developing chronic back pain and other related issues.

Modern vehicles primarily utilize serpentine belts due to their design advantages. A single serpentine belt can drive multiple accessories, reducing weight and complexity in comparison to older belt systems that used separate belts for each accessory. This configuration also allows for a more compact engine design, which can lead to improved fuel efficiency.

3. Motivation for Weight Loss For many, wearing an abdominal belt serves as a psychological trigger, reminding them of their fitness goals. This motivation can lead to more consistent workouts and healthier lifestyle choices.

The toothed design of neoprene timing belts is another key feature. The teeth mesh with sprockets or pulleys, allowing for positive engagement. This ensures that the belt does not slip, which is critical in applications requiring precise timing and synchronization. This characteristic makes neoprene timing belts particularly suitable for applications where accurate timing is necessary, such as in automotive engines or high-speed machinery.

Features of the W211 PK V-Ribbed Belt

Conclusion