Aesthetic Integration

Scrap steel is melted in a crucible, induction, electric arc or reverberator furnace at 1500° C or 2700°F. The required alloys carbon and silicon, and flux to bind to impurities to create slag are added to the molten iron. The slag is lighter than iron and floats to the top from where it is removed. The molten iron is then poured into a metal ladle with a long handle which is then carried to the sand molds contained in the metal frames and poured through the riser. Green sand has a lower auto-ignition temperature than the temperature of the molten iron allowing the organic material present in the sand to use up all the oxygen present in the mold, preventing oxidation of the manhole cover. Trapped gasses can cause bubbles in the casting.

One significant application of osmadrain in 4D906 is in the development of smart materials. These materials can adaptively respond to environmental changes, such as fluctuations in temperature or pressure. Imagine a scenario where a building's façade changes its properties based on impending weather conditions, optimally regulating internal temperatures while minimizing energy costs. By employing osmadrain principles, these materials could become effective in managing moisture levels, thus enhancing the durability and comfort of living spaces.

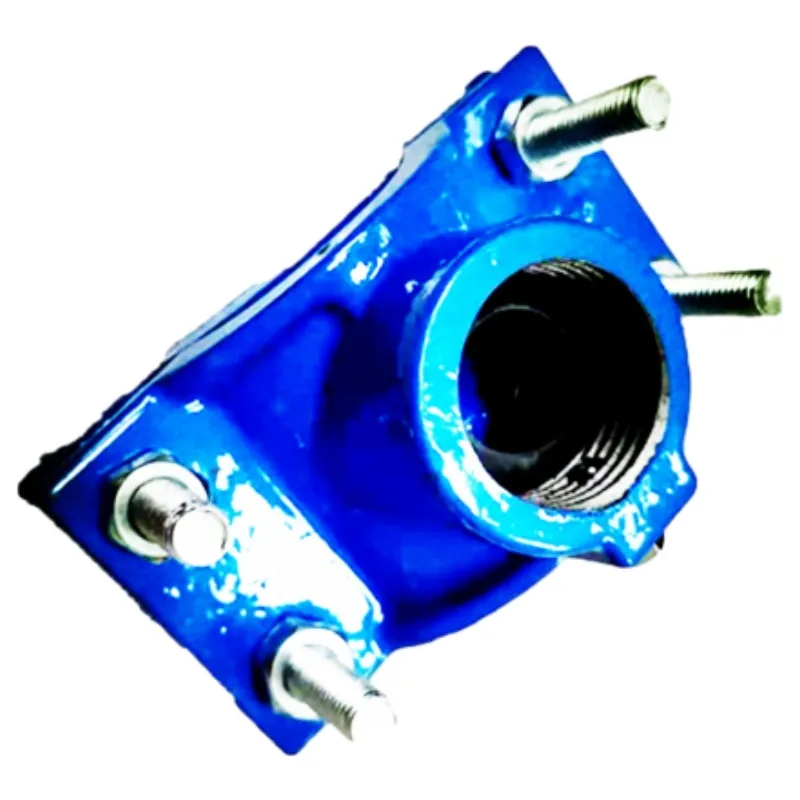

Moreover, the clamps are designed to withstand a range of environmental conditions. They do not typically corrode easily, making them suitable for various applications, including outdoor and underground installations.

The Old Dustbin A Hidden Treasure of Memories

Aren’t manholes just for sewers?

The metal typically used for manhole covers is cast iron. Cast iron is created by melting iron, which is poured into a mold. This process results in a strong and durable finished product. There are two main types of cast iron used to create precast manhole covers which include gray cast iron and ductile cast iron.

Space-Saving Designs

pedal type dustbin

A yard gully, often referred to as a drain or a grating, is a recessed area designed to collect and redirect surface water away from properties and public spaces. Heavy-duty variants are specifically engineered to handle substantial volumes of water and endure the stresses of high traffic, making them suitable for both residential and commercial applications.

The grating component is crucial as it serves multiple purposes it prevents larger debris from entering the drainage system, thereby reducing the likelihood of clogs and blockages, and it also promotes an efficient flow of water. The size and spacing of the grating openings can be customized based on specific drainage needs and environmental conditions, making vertical grating drains adaptable to various applications.

In terms of aesthetics, modern quick stuff bike racks are designed to blend seamlessly into urban landscapes

. They are often available in various colors and styles, allowing city planners and property managers to choose options that complement their surroundings. This attention to design not only enhances the visual appeal of public spaces but also encourages more people to adopt cycling as a mode of transport.