The tiles are provided in different specifications and patterns, thus delivering decorative effects with diversified artistic styles. And, they also have different suspension modes that help bring out the full functions in these suspension materials.

Location is a critical factor in access panel installation. Ceiling access panels should be placed in easily reachable areas, ideally at heights that do not require special equipment for access. According to many building codes, panels should also be situated away from high-traffic areas to minimize the risk of damage and ensure they are not obstructed by fixtures like lights or ceiling fans. Accessibility for maintenance and emergency situations is a priority, as building systems may need quick and unhindered access during repairs or inspections.

ceiling access panel code requirements

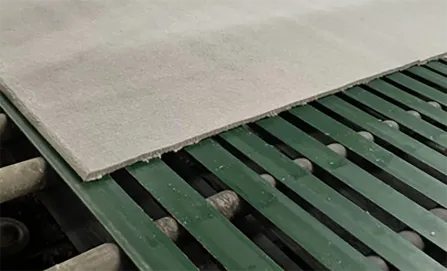

4. Inserting Ceiling Tiles Finally, ceiling tiles are placed into the grid, completing the drop ceiling.

When it comes to the construction and renovation of residential and commercial properties, accessibility is a key concern. One often overlooked aspect of this is the installation of access panels. Among various types of access solutions, flush mount ceiling access panels stand out due to their aesthetics and functionality. In this article, we will explore the significance of these access panels, their applications, and the advantages they offer.

They prevent leaks, minimize wear and tear, and ensure the safe operation of equipment by preventing the ingress of contaminants They prevent leaks, minimize wear and tear, and ensure the safe operation of equipment by preventing the ingress of contaminants

They prevent leaks, minimize wear and tear, and ensure the safe operation of equipment by preventing the ingress of contaminants They prevent leaks, minimize wear and tear, and ensure the safe operation of equipment by preventing the ingress of contaminants Therefore, maintaining a healthy oil seal is essential for preserving the integrity and longevity of the shock absorber system Therefore, maintaining a healthy oil seal is essential for preserving the integrity and longevity of the shock absorber system

Therefore, maintaining a healthy oil seal is essential for preserving the integrity and longevity of the shock absorber system Therefore, maintaining a healthy oil seal is essential for preserving the integrity and longevity of the shock absorber system