pvc gypsum ceiling design

-

...

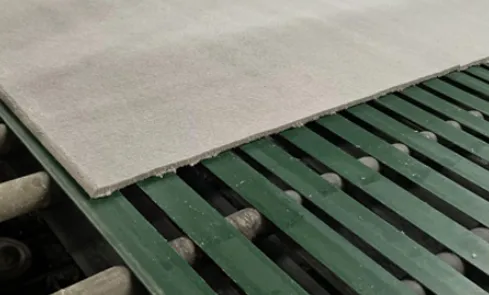

Another compelling advantage of mineral fiber planks is their excellent fire resistance. Being made from inorganic materials, they do not combust, thereby providing an additional layer of safety to any structure. This characteristic is especially crucial in commercial buildings and public spaces, where fire codes and regulations are stringent. The ability of mineral fiber planks to withstand high temperatures without contributing to the spread of flames is a significant asset in enhancing the overall safety of a property.

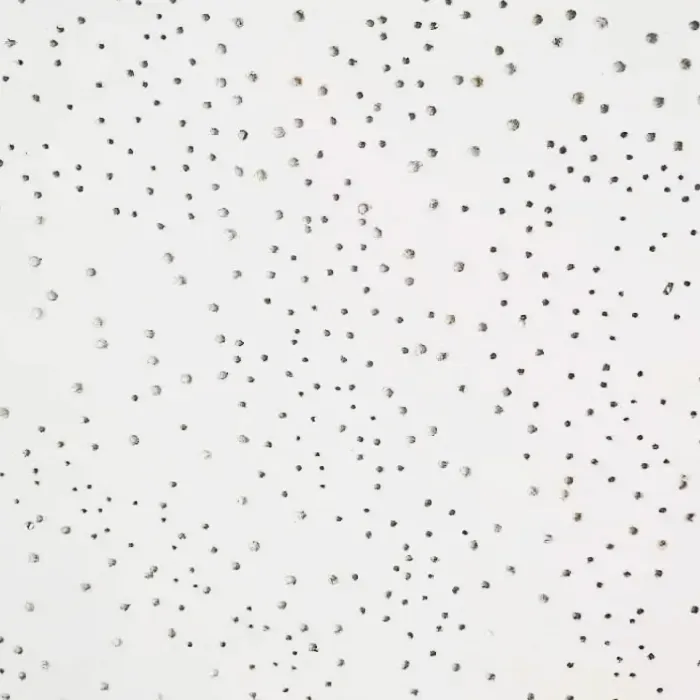

mineral fiber planks

...