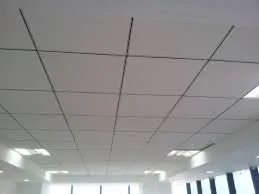

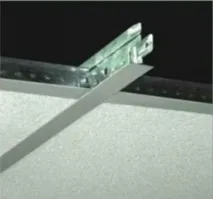

drop ceiling main tee

Links

-

Reducing operational costs is a top priority in mining and quarrying, where the cost of equipment maintenance and energy consumption can significantly impact profitability. The efficient operation of horizontal slurry pumps plays a key role in achieving cost savings. By selecting the right centrifugal pump for slurry and maintaining it with AH slurry pump parts, operators can optimize energy use, reduce wear on pump components, and minimize the need for costly repairs. The long-term benefits of efficient slurry pump operation include lower energy bills, reduced maintenance costs, and improved overall efficiency in mining and quarry processes.

-

Function: The pump casing contains the slurry and guides it through the pump.

-

- Throat Bush: Protects the area around the impeller eye where the slurry first enters.

-

The impeller is a rotating component within the pump that transfers energy from the motor to the slurry. It plays a significant role in creating the flow and pressure necessary to move the slurry through the system. Impellers for slurry pumps are typically heavier and more robust than those used in standard pumps to withstand the harsh conditions encountered in abrasive applications. Their design can vary, with options for different shapes and sizes to accommodate specific types of slurries.

-

Wear Factors: Liners experience wear from the continuous contact with the slurry.

-

In firefighting systems, propeller pumps also play a crucial role. They provide the necessary pressure and volume of water needed to combat fires effectively. Their capability to move large quantities of water quickly makes them a reliable choice for fire departments, particularly in high-risk areas where rapid response is critical.

-

-

- Select the impeller design that best handles the slurry's characteristics (e.g., closed impellers for abrasive slurries, open impellers for large particles).

-

In order to broaden the application field of products and improve the market competitiveness of products,MineMaxx stepped up the implementation of the new product technology reserve strategy. According to the feedback of marketing personnel and relevant users as well as the market research of technical personnel, it comprehensively carried out the technical reserve of different types of new products, such as ceramic desulfurization pumps, froth slurry pumps, which greatly shortened the product delivery cycle and improved user trust.

-

a. Performance Curves:

-

In conclusion, sewage pump impellers are integral to wastewater management systems. By understanding their types, materials, and maintenance, operators can make informed decisions that enhance the efficiency and reliability of sewage pumping operations, ultimately contributing to effective waste management solutions.

-

-

a. Sealing Mechanisms:

-

a. Sealing Mechanisms:

-

Comparing Vertical and Horizontal Pumps: Key Considerations

-

- Most slurry pump manufacturers provide selection charts that correlate slurry characteristics and operating conditions with suitable pump models.

-

-

Understanding Sewage Pump Impellers A Key Component in Waste Management

-

- Volute Liners: Protect the pump casing in the volute section.

-

Wear Factors: Liners experience wear from the continuous contact with the slurry.

-

One of the most significant advantages of vertical multistage centrifugal pumps is their compact footprint. In deep pit applications, space is often at a premium, and the vertical design allows for efficient use of limited space. These pumps are designed to handle high pressures while occupying minimal horizontal space, making them ideal for applications where surface area is restricted. The multistage configuration also enables these pumps to deliver high pressure over long distances, which is particularly useful in deep pit environments where the pump needs to lift slurry from significant depths. By optimizing the design of vertical multistage centrifugal pumps, engineers can ensure that these pumps provide reliable performance in even the most confined spaces.

-

Function: Bearing assemblies support the pump shaft and ensure smooth operation.

-

Function: Bearing assemblies support the pump shaft and ensure smooth operation.

-

6. Bearing Assemblies

-

- Check the power requirements and ensure compatibility with your available power supply.

-

Materials: Materials used for shaft sleeves include hardened stainless steel and ceramic-coated materials.

-

4. Shaft Sleeves

-

-

-

Function: Liners protect the pump casing from the abrasive action of the slurry.

-

-

Flow Rate Measurement in Horizontal Centrifugal Slurry Pump

-

Function: Liners protect the pump casing from the abrasive action of the slurry.

-

Vertical stage pumps are a type of multistage pump that is designed to handle high-pressure applications. These pumps are characterized by their ability to generate high pressure through multiple stages, each adding to the total pressure head. Vertical stage pumps are particularly useful in applications where a significant pressure increase is needed, such as in high-rise building water supply systems, boiler feed applications, and pressure boosting systems. The vertical design of these pumps allows for a compact, efficient solution that can deliver the necessary pressure without taking up excessive space. By selecting the appropriate vertical stage pump for your system, you can ensure that your fluid handling needs are met efficiently and effectively.

-

2. Use a Selection Chart or Software

-

-

Monitoring Wet Parts for Optimal Pump Performance

-

The Role of Vertical Stage Pumps in High-Pressure Applications

-

1. Impellers

-

-

-

Moreover, the volute's cross-sectional area is carefully calculated to match the flow rate and pressure requirements of the system. An oversized volute may lead to low efficiency, as the fluid may not maintain its velocity to generate adequate pressure. Conversely, a volute that is too small can cause excessive pressure buildup, risking damage to the pump and downstream equipment.

-

Understanding the Basics of High Pressure Vertical Pumps

-

-

-

1. Understand Your Application Requirements

-

- Type of Slurry: Determine if the slurry is abrasive, corrosive, or contains large particles.

-

-

- Angular Contact Ball Bearings Product Guide and Specifications Overview

- 28580 bearing

- weizi bearing bearing ball deep groove

- Roulements à contact angulaire - Performance et Précision

- weizi bearing bearing pressing machine

- weizi bearing cylindrical roller bearing supplier

- weizi bearing nj 206 bearing

- weizi bearing 23244 bearing

- Similar title to 4T L44649 Bearing can be Replacement Bearing for 4T L44649, High Quality and Durable

- Design and Applications of Single Thrust Ball Bearings in Machinery Systems