Additionally, the precision offered by cylinder arm sewing machines is vital in craftsmanship. Accurate stitching provides not only aesthetic appeal but also structural integrity to leather goods. Products that are well-stitched are more durable and can withstand the test of time, which is essential in a market that values quality leather goods.

2. Enhanced Durability The reinforced seams created by a double stitch machine provide extra strength, reducing the likelihood of seams unraveling over time. This quality is vital for garments that undergo intensive use, ensuring customer satisfaction and reducing return rates.

One of the key advantages of a long arm heavy duty sewing machine is its extended arm. This feature allows you to work on larger projects such as quilts, curtains, and upholstery with ease. The extra space gives you more room to maneuver the fabric and makes it easier to sew straight and even seams. This is particularly useful when working on bulky or intricate designs that require precision and accuracy.

The Evolution of Leather Sewing Machines

what does an overlocker do. The machine is designed to work with materials like jersey, spandex, and Lycra, which can be challenging to sew with a regular machine. The overlocker's differential feed system helps to prevent stretching or puckering of the fabric, resulting in smooth, even seams that move with the body.

In conclusion, the hi-speed lockstitch sewing machine is a cornerstone of modern textile production. Its ability to deliver high-speed, reliable stitching makes it an indispensable tool in various sectors, from fashion to upholstery. As technology continues to evolve, these machines are expected to incorporate even more innovative features, further enhancing their efficiency and capabilities.

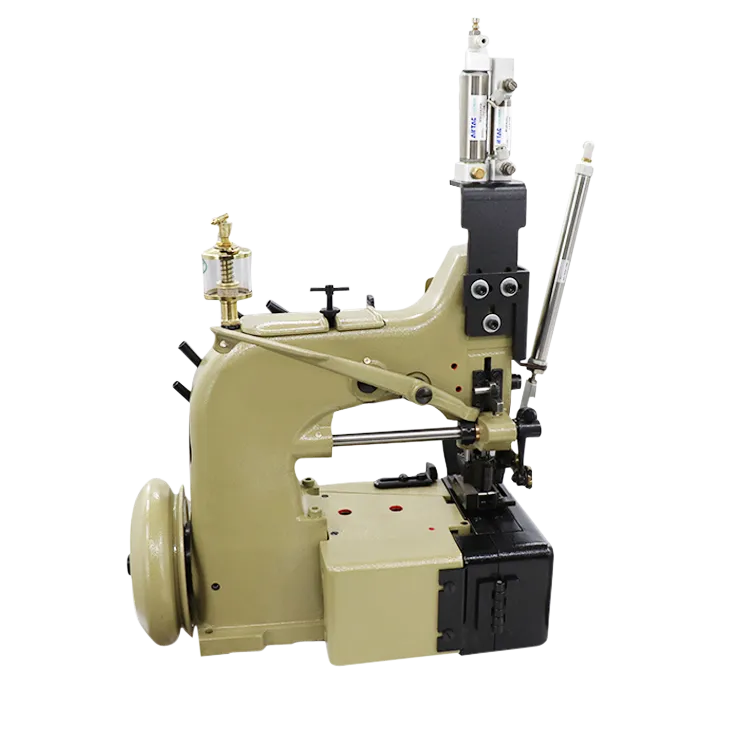

In conclusion, automatic bag closer machines play an essential role in the packaging industry by enhancing efficiency, ensuring product quality, and contributing to cost savings. As industries continue to evolve and demand higher productivity, these machines will remain vital tools for manufacturers. Investing in automatic bag closer technology is not just a matter of operational convenience; it is a strategic move towards achieving sustainable growth and meeting the ever-increasing expectations of consumers.

Heavy-Duty Sewing Machines: While priced higher than standard domestic machines, they are considerably more affordable than industrial machines. They strike a balance between enhanced capabilities and cost.

3. User-friendly Interface Many programmable sewing machines are designed with user-friendly interfaces that include touch screens, making it easy to navigate through menus, select patterns, and adjust settings. This intuitive design helps reduce the learning curve, allowing new users to quickly become proficient in their machine’s features.

programmable pattern sewing machine

If you’re in the market for a double needle walking foot sewing machine, there are various avenues to explore. Local sewing machine retailers often carry a range of models, providing a chance to see the machines in action before making a purchase. Additionally, online marketplaces like Amazon, eBay, and specialized sewing websites offer a wide selection of machines at competitive prices.

Since leather can be thick and unwieldy, using interfacing or stabilizers can add extra support to your seams. Applying a temporary adhesive or a lightweight interfacing to the back of the leather can help prevent stretching and create a cleaner finish. When sewing, hold the pieces firmly together to avoid slipping, which can lead to uneven seams.

universal walking foot sewing machine. These machines are equipped with a range of stitches and features that allow you to tackle a variety of sewing projects. Whether you are sewing garments, home décor, or accessories, a walking foot sewing machine can handle it all. Additionally, many models come with adjustable presser foot pressure and stitch length, allowing you to customize your sewing experience to suit your specific needs.

universal walking foot sewing machine. These machines are equipped with a range of stitches and features that allow you to tackle a variety of sewing projects. Whether you are sewing garments, home décor, or accessories, a walking foot sewing machine can handle it all. Additionally, many models come with adjustable presser foot pressure and stitch length, allowing you to customize your sewing experience to suit your specific needs. For sewists working with woven fabrics, the coverstitch can create an excellent alternative to serging for seam finishes, providing a clean edge that resists fraying while allowing for some stretch. It is particularly advantageous in garment construction that involves bias-cut panels where flexibility is essential.

The functionality of compound feed sewing machines makes them ideal for a wide variety of applications. They are especially beneficial in industries where heavy fabrics, such as leather, vinyl, and canvas, are the norm. For instance, manufacturers of bags, luggage, and outdoor gear rely on these machines to produce durable seams that withstand wear and tear. Furthermore, in the automotive industry, compound feed machines are employed to sew upholstery materials, ensuring that seams are not only strong but also aesthetically pleasing.

What is a Heavy Duty Basic Sewing Machine?

The position of the needle as it enters and exits the leather is fundamental to achieving secure stitches. Ideally, you should hold the leather firmly but not excessively tight, as this can distort the material. When inserting the needle, aim to enter the leather at a 90-degree angle to maintain consistent stitch depth. This angle not only ensures a cleaner penetration but also helps create uniform spacing between stitches.

positioning needle for hand sewing leather

Overlock chain stitches are widely used in the fashion industry. They are ideal for constructing garments such as t-shirts, leggings, and activewear, where both comfort and durability are essential. The flatlock seam created by this technique provides a smooth finish that is less likely to irritate the skin, making it a preferred choice for garments worn directly against the body.

overlock chain stitch

If you want to add a professional touch to your sewing projects, learning how to use a twin needle on your sewing machine is essential. Twin needles allow you to create two parallel rows of stitches simultaneously, which not only enhances the aesthetic of your garments but also provides added durability. Here’s a comprehensive guide on how to effectively use a twin needle.

Choosing a long arm heavy duty zigzag sewing machine is an investment in creativity, efficiency, and enjoyment. With its powerful performance, ample workspace, and versatile stitching options, this machine provides the tools needed to tackle a diverse range of sewing projects. Whether you're sewing for fun or crafting items for sale, the long arm heavy duty zigzag sewing machine promises to elevate your sewing experience and bring your visions to life. So why wait? Dive into the world of sewing with a reliable companion that can handle everything you throw at it!

Moreover, preparation is essential when working with thicker fabrics. Before sewing, it's advisable to pre-wash and iron the fabric to reduce shrinkage and improve the accuracy of the seam. Cutting the fabric with precision is also important, as clean edges ensure a better fit and finish. Using fabric pins to secure layers will help maintain alignment as you sew. Given the limitations of handheld machines, maintaining control over the fabric is vital for achieving neat results.

1. Increased Efficiency The ability to sew through thick materials without jamming or breaking needles significantly increases productivity. Heavy duty motors enable seamstresses to complete projects quicker and with more confidence in the machine's performance.

B. Adding Decorative Stitches and Embellishments:

Readers will discover ways to enhance their projects with decorative stitches and embellishments. We’ll showcase techniques like appliqué, free-motion embroidery, and using specialty threads to create unique and eye-catching designs.

Children’s Items: Children’s items can include various products, such as stuffed animals, bibs, small backpacks, and sturdy play clothes.

Needle feed sewing machines are widely used across different sectors of the textile industry. In the garment manufacturing sector, they are essential for sewing complex patterns, fortifying seams, and working with layered fabrics. This capability makes them particularly valuable for producing high-quality clothing items, including suits, dresses, and outerwear.

The Charm of Chinese Hand Crank Leather Sewing Machines