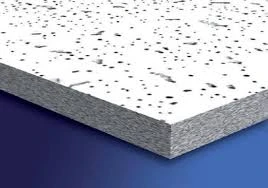

different types of ceiling panels

Links

- In the pharmaceutical industry, HPMC is commonly used as a coating agent for tablets and capsules. It helps to improve the dissolution rate and bioavailability of drugs and provides a protective barrier for sensitive ingredients. HPMC is also used as a sustained-release agent in drug formulations, allowing for controlled release of active ingredients over a period of time.

-

In conclusion, Methyl Hydroxyethyl Cellulose is a vital cellulose derivative that plays a crucial role in numerous sectors, especially in China. Its multifunctional properties, coupled with the growing trend towards sustainable and eco-friendly products, underscore its significance in modern formulations. As industries strive to meet changing consumer preferences and environmental standards, MHEC stands out as a reliable and effective solution. The future looks promising for MHEC, with ongoing innovations and an ever-expanding range of applications on the horizon.

Applications in Pharmaceuticals

May not be suitable for all applications due to its synthetic nature

Key Properties of HPMC

First Aid Measures

Conclusion

Hydroxyethyl cellulose is a nonionic water-soluble cellulose ether product that is widely used in architectural coatings, petroleum, polymer polymerization, medicine, daily necessities, papermaking inks, fabrics, ceramics, construction, agriculture and other industries. It has the functions of thickening, bonding, emulsifying, dispersing, and stabilizing, and can retain water, form films, and provide protective colloid effects. Easily soluble in cold and hot water, solutions with a wide viscosity range are available. One of the faster cellulose ethers.

In the daily chemical industry such as toothpaste, soap, lotion and cosmetics, and ointment, Hydroxyethyl Cellulose acts as a thickener, dispersing agent, binder and stabilizer to increase the density, lubrication, and mercerized appearance of products. SidleyCel™ Hydroxyethyl Cellulose products are applicable to personal care and cosmetics, with purity over 95%. The reliable quality and high stability have been recognized by customers.

2. Food Industry In food applications, HPMC is utilized as a thickening agent and emulsifier. It enhances the texture and shelf-life of various food products, including sauces, dressings, and bakery goods. Moreover, it is often used in vegetarian and vegan food formulations as a substitute for eggs and other animal-derived products.

Introduction

5. Agriculture HEC is used in the formulation of agricultural products, such as pesticides and herbicides, where it serves as a suspending agent. It aids in the even distribution of active ingredients, enhancing the efficiency of these products in pest management.

Understanding HPMC Density Significance and Applications

Hydroxypropyl Methylcellulose (HPMC), a cellulose ether, has gained significant attention in various industries due to its unique properties and versatility. This polymer is derived from natural cellulose, which is modified to enhance its functional capabilities. One of the most appealing aspects of HPMC is its ability to form thick solutions and gels, making it an essential ingredient in pharmaceuticals, food products, construction materials, and personal care items. In this article, we will explore the characteristics, benefits, and applications of HPMC.

HPMC is widely used in various sectors due to its versatility. In the food industry, it serves as a thickening agent, stabilizer, and emulsifier, helping to improve the texture and shelf life of products. Food items such as sauces, dressings, and baked goods may include HPMC to achieve desired viscosity and consistency.

The pricing of redispersible polymer powder is influenced by various factors, including raw material costs, production processes, and market demand. The primary raw materials used in producing these polymers — such as vinyl acetate, ethylene, and acrylate — are subject to price fluctuations that can directly impact the overall cost of the final product. For example, if the petroleum prices rise due to geopolitical tensions or supply chain disruptions, the cost of these raw materials may also increase, leading to higher prices for redispersible polymer powders.

HPMC is derived from cellulose, a natural polymer obtained from plant cell walls. The modification process introduces hydroxypropyl and methyl groups into the cellulose structure, resulting in a water-soluble compound that retains gel-forming and thickening capabilities. Available in various molecular weights and substitution degrees, HPMC can be tailored to meet specific performance criteria required in construction.

On the other hand, it is equally important for customers to be aware of how to utilize the contact number effectively. Being prepared with specific questions or issues before making a call can lead to more productive conversations. Customers should, therefore, gather relevant information about their inquiries and clearly articulate their needs when reaching out. This not only saves time but also ensures that the interaction is beneficial for both parties.

Additionally, HPMC is non-toxic and biocompatible, making it safe for ingestion in pharmaceutical applications. Its stability under various pH conditions allows it to be utilized in a wide range of formulations, from solid dosage forms like tablets and capsules to liquid formulations such as suspensions and emulsions.

Conclusion

Conclusion

In conclusion, HPMC density is a fundamental property that directly impacts its functionality across various applications. From pharmaceuticals to food production and construction, density affects how HPMC interacts with other ingredients and influences the final product's performance. As demand for HPMC continues to grow, particularly due to its versatility and biodegradable nature, ongoing research into its density and related properties will be vital. This research not only enhances our understanding of HPMC but also pushes the boundaries of its application in innovative ways, potentially leading to new products and improved formulations across multiple industries. Understanding and mastering HPMC density is thus a key ingredient for success in any field that employs this remarkable polymer.

The Importance of Solubility

4. Market Expertise and Trends HPMC importers often act as valuable consultants to their clients, providing insights into market trends, pricing, and potential supply issues. They keep a finger on the pulse of the industry and can advise their clients on best practices for formulation and application, thereby enhancing the overall value of their service.

The viscosity of HPMC plays a crucial role in determining the performance of the end product. For instance, in the pharmaceutical industry, the viscosity of HPMC can influence drug release rates from hydrophilic matrices and impact the stability of suspensions. In food applications, the viscosity contributes to the mouthfeel and texture of sauces and dressings. In construction, appropriate viscosity ensures that mortar and adhesive formulations maintain their application properties while setting.

What is HPMC Used For?

Pros of Methylcellulose:

Quality control is paramount in the manufacturing process. Leading MHEC manufacturers employ sophisticated techniques to ensure that their products meet requisite standards. This includes comprehensive testing for viscosity, gel formation, and solubility in various temperatures and concentrations to ensure consistency and performance across batches.

Hydroxypropyl methyl cellulose ether (HPMC) is a synthesized polymer derived from cellulose, a natural polymer found in plant cell walls. As one of the most versatile and widely used cellulose ethers, HPMC finds applications across various industries, including pharmaceuticals, food, cosmetics, and construction.

4. Versatility in Formulations One of the remarkable qualities of HPMC is its versatility. It can be combined with various additives and materials to develop customized putty formulations that cater to specific needs, such as enhanced flexibility, increased strength, or improved moisture resistance.

HPMC is a non-ionic, water-soluble compound derived from natural cellulose. Its unique chemical structure incorporates hydroxypropyl and methyl groups, which enhance its solubility and thermal stability. HPMC powders exhibit high viscosity, excellent gel-forming capabilities, and improved adhesion properties. These characteristics make HPMC an ideal additive for many formulations, providing both thickening and binding functionalities.

Gelatin Capsules

3. Food Industry In food applications, HPMC functions as a food additive, providing texture, moisture retention, and emulsification. It is used in a variety of products, including sauces, dressings, and baked goods, due to its ability to enhance consistency and improve mouthfeel.

In the food industry, HPMC serves multiple functions. Its emulsifying and thickening properties are leveraged in various food products, including sauces, dressings, and baked goods. Notably, it is often used as a fat replacer, enhancing the texture and mouthfeel of low-fat and reduced-calorie products. Additionally, HPMC is considered a safe food additive and is listed under the Food and Drug Administration (FDA) as Generally Recognized as Safe (GRAS), assuring consumers of its safety for consumption.

hydroxypropyl methyl

Applications of MHEC

mhec-methhyl hydroxyethyl cellulose manufacturer

Most reputable factories adhere to ISO certifications and have implemented advanced laboratory facilities that conduct a range of tests, including viscosity, purity, and particle size distribution. These measures guarantee that the HPMC produced not only meets but exceeds customer expectations, thus solidifying China's reputation in the global market.