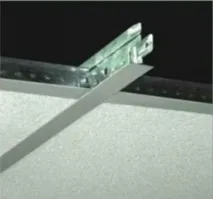

acoustic mineral fiber board

Links

-

To maximize the efficiency of HVAC vacuum hoses, it’s essential to follow best practices during their use

-

5. Flexibility Despite their robust design, wire braided hoses maintain a level of flexibility that allows for easy maneuvering and installation in complex systems, reducing potential complications during assembly.

-

3. Durability These hoses are built to last. With robust outer covers, they can withstand harsh environmental conditions, including exposure to chemicals, oil, and extreme temperatures, which extends the hose's operational life.

-

Applications

-

4. Thermoplastic Hoses Made from thermoplastic material, these hoses offer flexibility and can be used in a variety of applications, especially where space is limited.

-

When discussing high-pressure hoses, pressure ratings are crucial for their correct application. The percentages, such as 1% and 4%, refer to the hose’s ability to handle pressure in specific contexts.

-

- Ống hồi Đưa chất lạnh từ dàn bay hơi trở về máy nén.

-

يمثل مصنع الخرطوم المضفر رمزًا للتفوق في صناعة الخراطيم. من خلال الابتكار والجودة العالية، يمكن لهذا المصنع تقديم منتجات تلبي متطلبات العملاء بأعلى مستوى من الأداء. لا شك أن الخرطوم المضفر سيظل عنصرًا أساسيًا في العديد من الصناعات، حيث يواصل المصنع تعزيز ثقافة الابتكار والجودة لضمان استمرار نجاحه في المستقبل.

-

PTFE Hose for Power Steering An Essential Component in Automotive Performance

-

The automotive industry also benefits from hydraulic hose hand crimpers. They are used to create and repair hoses for brake systems, power steering, and transmissions. The ability to work with hydraulic hoses directly contributes to vehicle safety and reliability, making it imperative for mechanics to have access to quality hand crimpers.

-

1. Preparation Start by cutting the hose to the desired length and inserting the fitting into the end of the hose. Ensure that the fitting is fully seated.

-

Types of Hydraulic Hose Crimpers

-

Die regelmäßige Wartung von industriellen Schläuchen und Fittings ist unerlässlich, um deren Lebensdauer zu verlängern und die Sicherheit am Arbeitsplatz zu gewährleisten. Überprüfungen auf Risse, Abnutzungen oder andere Beschädigungen sind notwendig, um das Risiko von Ausfällen und Unfällen zu minimieren. Auch die korrekte Lagerung und Handhabung der Schläuche ist von Bedeutung. Diese sollten an einem kühlen, trockenen Ort ohne direkte Sonneneinstrahlung gelagert werden, um Schäden durch Umwelteinflüsse zu vermeiden.

-

Understanding 1% and 4% High Pressure Hoses A Comprehensive Overview

-

1. Durability Unlike plastic alternatives, rubber hoses can withstand abrasions, cuts, and UV exposure. This extended lifespan makes them a cost-effective choice over time.

-

3. Flexibility Despite their strength, SAE 100R2AT hoses are remarkably flexible, allowing for easier routing and installation in tight spaces.

-

Applications Across Industries

-

2. Efficiency A mobile hose crimper can produce hose assemblies quickly, which is critical in industries where downtime can be costly. With the ability to make repairs or replacements on-demand, businesses can maintain continuous operations and minimize disruptions.

Another critical factor is the temperature range. Some chemicals can generate heat during transfer or react exothermically, thus requiring hoses that can handle elevated temperatures. Additionally, pressure ratings are essential; ensuring that the hose can manage the pressure generated in the system avoids catastrophic failures that could lead to spills or leaks.

Proper maintenance of sandblast rubber hoses is crucial to ensure optimal performance and safety. Routine inspections should be conducted to check for signs of wear, kinks, or cracks. Keeping the hoses clean and free of abrasive materials is also essential to prolong their lifespan.

2. Reinforcement The hose features two braids of high-tensile steel wire, offering substantial strength and flexibility. This reinforcement allows the hose to withstand high pressures, typically up to 4000 psi (pounds per square inch). The dual layer of braiding ensures that the hose maintains its shape and integrity under extreme conditions.

3. Use Protectors To protect hose ends from wear, consider using hose fittings with metal or rubber protectors.

1. Durability and Strength The braided construction significantly enhances the hose's strength, allowing it to withstand high pressure without bursting. This resilience is paramount in applications where bursts can lead to dangerous gas leaks.

There are several advantages to using hydraulic hose hand crimpers. Firstly, they offer a high level of precision. Many hand crimpers come with adjustable settings, allowing users to achieve the exact pressure required for different hose and fitting combinations. This customization ensures the integrity of the connection while minimizing the risk of damage to either component.

hydraulic hose hand crimper

Hydraulic hoses play an indispensable role in the performance and efficiency of excavators. As essential components of the hydraulic system, they facilitate the machine’s various functions and contribute to successful project outcomes.

3. Electric Crimpers These offer the advantages of speed and precision in crimping operations, making them suitable for high-volume production environments.

Construction of Braided Automotive Hoses

1. Clean Regularly After use, clean the exterior of the hoses to remove refrigerant residues or contaminants. This prevents cross-contamination during future use.

4. Personnalisation

4. Self-Recovery Rubber hoses have excellent self-recovery properties, meaning they can return to their original shape after being bent or compressed, reducing wear and tear.