drywall grid ceiling system

Links

- Overall, butyl rubber tape is a versatile and reliable product that offers a wide range of applications in various industries. With its strong adhesion properties, flexibility, and ease of application, it is a popular choice for sealing, waterproofing, and insulating needs in China.

- 5. Press the tape firmly into place, using a roller or your hand, to ensure good adhesion.

-

-

- Aluminium

-

-

Backing construction, thickness, and dielectric strength are factors of a tape’s grade. The grade is highly indicative of its performance quality. Tape backings are either monomeric or polymeric, polymeric being the more durable of the two.

-

- Excellent Tack: Rubber adhesives exhibit excellent tack, which refers to their ability to bond quickly upon contact with a substrate. This tackiness enables efficient and effective bonding, minimizing the need for additional pressure or extended dwell time.

-

Creates a strong, seamless, waterproof and electrically insulating layer.

- High-temperature insulation tape is primarily utilized in environments where conventional materials would wilt or melt. Imagine the blistering heat of an engine compartment, the scorching air around furnaces, or the searing temperatures within ovens and kilns. These are the battlegrounds where this tape proves its mettle, protecting components from thermal damage and electrical shorts while maintaining its integrity.

This tape is easy to use, sticks to itself well and is available in convenient, 6 metre long rolls.

You should use a minimum of two half-lapped layers of vinyl tape to insulate and jacket low-voltage components. A half-lap (see Figure above) consists of overlaying each turn by one-half the width of the tape. The general rule of thumb calls for a tape thickness of 1.5 times the thickness of existing wire or cable insulation. In every case, tension on the tape should be sufficient to conform the tape evenly to the surface. A slight reduction in tension is encouraged for the final wrap. Trim the tape end and allow it to return to shape before pressing down with the thumb to avoid lifting or flagging.

The key feature of amalgamating rubber tape is its ability to effectively bond to itself when stretched and wrapped around an object. This self-amalgamating characteristic creates a strong and durable seal that is resistant to water, chemicals, UV rays, and extreme temperatures. As a result, this tape is widely used for electrical insulation, plumbing repairs, cable management, and automotive applications.

Aside from its waterproof capabilities, butyl rubber tape is highly resistant to UV rays, aging, and extreme temperatures. This durability means that the tape will not degrade quickly when exposed to sunlight or harsh weather conditions, making it suitable for outdoor use. Users can expect long-lasting results, which reduces the need for frequent replacements and repairs.

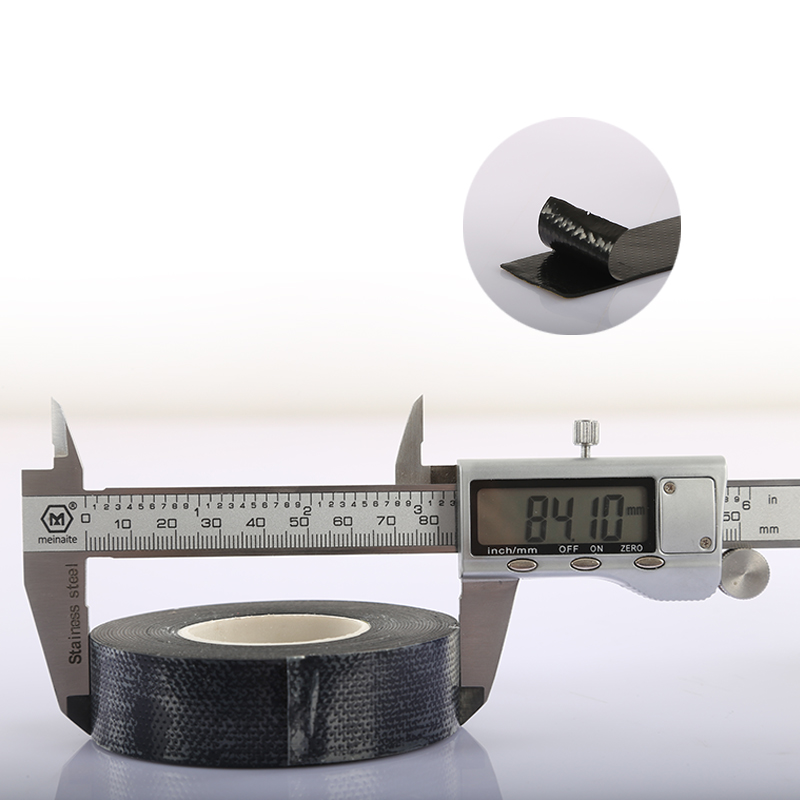

butyl rubber tape

3. Measure and Cut Measure the length of the gap that needs sealing and cut the butyl weather stripping accordingly. It’s advisable to cut a little longer than necessary, allowing for a snug fit.

Whether you need to repair a leaky pipe, insulate an electrical connection, or secure an object in place, 3M amalgamating tape is sure to get the job done efficiently and effectively. Give it a try today and experience the benefits of this versatile tape for yourself.

What is Butyl Tape?

High voltage self-fusing rubber tape is widely used in various industries, including