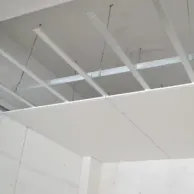

types of drop ceiling grid

-

...

Links

- Regular maintenance of the rear shock absorber oil seal is essential to ensure the proper functioning of the suspension system and the safety of the vehicle. By keeping an eye on the condition of the seal and promptly replacing it when necessary, drivers can enjoy a smooth and comfortable ride, as well as peace of mind knowing that their vehicle is in good working order.

-

- Offers a high degree of strength

skeleton oil sealing. These foreign particles can cause significant damage to machinery if they enter the system, so it is essential to have a reliable sealing solution in place.

H7 or H8

2. If the nominal bore diameter exceeds 400 mm:

H7

Carboxylate Nitrile

Aspects to consider when selecting oil seals

When selecting the 75x100x10 oil seal for a specific application, it's essential to consider factors such as the operating temperature, speed, and pressure of the equipment. Different materials and designs are available for oil seals, each with its own set of characteristics and advantages. Consulting with a knowledgeable supplier or manufacturer can help you choose the right oil seal for your needs.

Both sealing types are popularly used in different mechanical engineering applications. How are they different? The article explains the fundamental working mechanism of both categories of seals.

When deciding on the best type of seal for a particular application, it is best to consider all aspects of the environment and its purpose. If the application requires a spring- loaded seal, that does not eliminate either the rotary shaft seal or the mechanical seal. If the equipment is operating in extreme temperatures, including situations where the rapid movement of the equipment creates extreme heat, a mechanical seal will hold up better than an oil seal.