tegular grid

1. Flush Access Panels These panels sit flush with the surrounding drywall, providing a seamless look. They can be painted over or textured to match the ceiling, making them nearly invisible.

access panel for drywall ceiling

1. Flush Access Panels These panels sit flush with the surrounding drywall, providing a seamless look. They can be painted over or textured to match the ceiling, making them nearly invisible.

Links

Another vital aspect of maintenance is timely replacement. A worn-out belt can lead to machinery malfunction, causing expensive downtime and repair costs. Implementing a proactive maintenance schedule can help operators identify potential issues before they escalate, ensuring continuous operation of the machinery involved.

3pk belts are versatile and are used in a multitude of applications across various industries. Some of the most common applications include

Conclusion

3. ความหลากหลาย ในดูไบ มีแหล่งฝังชิ้นส่วนรถยนต์มือสองจำนวนมาก ตั้งแต่ศูนย์อะไหล่รถยนต์ทั่วไปไปจนถึงตลาดเฉพาะ ซึ่งทำให้เจ้าของรถสามารถหาชิ้นส่วนที่ต้องการได้หลากหลายแบบ

2. Tension Adjustment Ensure that the belt maintains the correct tension. If it’s too loose or too tight, it can lead to premature wear or failure.

Understanding EPDM Rubber Properties, Applications, and Benefits

5. Ease of Installation Rough top V-belts are designed for user-friendliness, making installation straightforward. They can be fitted into existing machinery with relative ease, which minimizes downtime during setup or replacement. This factor is particularly valuable in fast-paced industrial environments where time is of the essence.

In industrial settings, V-belt clutches are utilized in machinery such as conveyors, compressors, and pumps. They are instrumental in applications that require frequent start-stop operations or where load fluctuations occur. By controlling the power transmission, V-belt clutches enhance operational efficiency and safety.

2. Listen for Unusual Noises Pay attention to any unusual sounds coming from the engine, such as squeaking or grinding, which may indicate a failing fan belt or issues with the timing belt.

5. Emergency Kits

The Importance of Wholesale Fan Belts in Automotive and Industrial Applications

The manufacturing process of these belts also plays a significant role in their overall quality. Precision engineering and rigorous quality control measures ensure that each belt meets stringent performance standards. High-quality ribbed belts undergo extensive testing, including dynamic endurance tests, to ensure they can handle the demands of modern vehicles efficiently.

Understanding Power Steering Pump Drive Belts A Key Component for Smooth Driving

- Oil Leakage If oil is leaking from the front of your engine, it could indicate a failed camshaft seal, which may affect the timing belt and necessitate replacement.

The appeal of vintage motorcycle belts extends beyond their aesthetic charm. Many people are drawn to them for their nostalgic value, as they evoke memories of iconic motorcycle brands like Harley-Davidson or Triumph, and the culture surrounding them. Wearing a vintage belt can evoke a sense of camaraderie among riders and enthusiasts, fostering connections based on shared interests.

4. Professional Inspections It’s wise to have a professional mechanic conduct comprehensive inspections during routine maintenance to catch any potential issues early.

Furthermore, the rise of electric vehicles (EVs) and hybrid technologies is also influencing the timing belt market. As the automotive industry moves towards more sustainable alternatives, the need for traditional internal combustion engines—and therefore timing belts—may diminish. However, while the shift to electric vehicles is underway, many existing vehicles still rely on timing belts. Thus, the importance of this component cannot be overstated in the current automotive landscape.

4. Professional Inspections It’s wise to have a professional mechanic conduct comprehensive inspections during routine maintenance to catch any potential issues early.

2. Brand and Quality The manufacturer of the drive belt plays a crucial role in its pricing. Well-known brands often charge a premium due to their reputation for quality, reliability, and performance. Conversely, generic or lesser-known brands may offer lower prices but could potentially compromise on durability and performance.

Conclusion

Maintenance and Care

4. Poly V Belts These belts have several small grooves and can transmit power more efficiently than standard V belts. They are often used in smaller, more compact mowers.

Regular inspections of the timing belt should be part of any vehicle’s maintenance routine. Signs of wear, such as fraying or cracking, indicate that it’s time for a replacement. Moreover, it’s advisable to check the belt tension and the condition of the pulleys, as a misaligned or worn-out pulley can lead to premature belt failure.

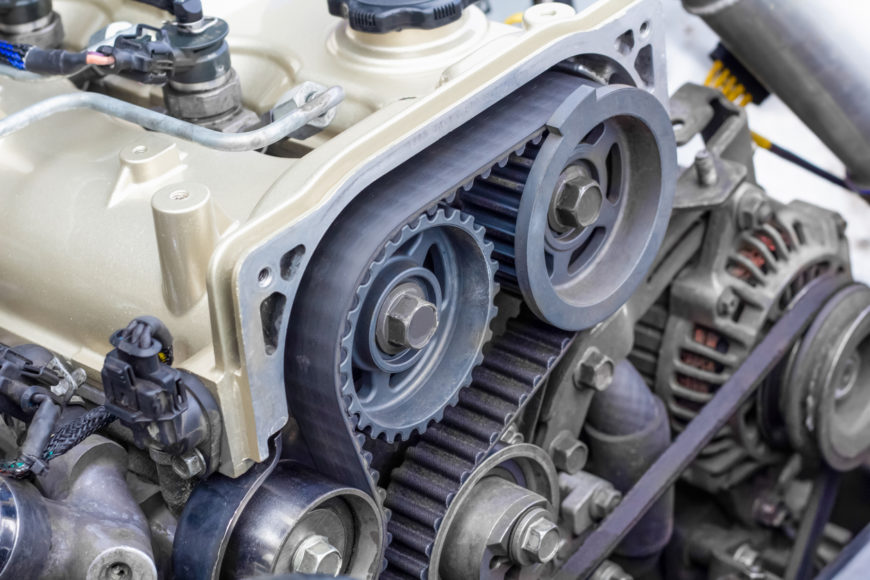

Tooth belt drives are incredibly versatile and are used in a wide array of applications. In the automotive industry, they play a critical role in engine timing systems, connecting the crankshaft to camshafts to ensure that the valves open and close at the correct intervals. This timing is essential for optimal engine performance and efficiency.

1. Identify Requirements Understand the power requirements, load capacity, and the operating conditions of the machinery to select an appropriate belt.

When it comes to maintaining your vehicle, one of the most critical components that require attention is the timing belt. The timing belt is an essential part of the engine; it synchronizes the rotation of the crankshaft and camshaft, ensuring that the engine's valves open and close at the right time during each cylinder's intake and exhaust strokes. If the timing belt fails, it can lead to severe damage to the engine, resulting in costly repairs. Therefore, understanding the costs associated with the timing belt replacement is vital for any car owner.

Maintenance and Care

To prolong the lifespan of the engine belt, regular inspections and timely replacements are vital. It is typically recommended to check the serpentine belt every 60,000 to 100,000 miles, but always refer to the vehicle’s owner manual for specific guidelines.

Understanding Car Engine Belts The Unsung Heroes of Your Vehicle

Construction and Operation

1. Robotics In robotic systems, precision is paramount. XL timing belts help in the accurate and smooth operation of robotic arms and components, ensuring tasks are executed with high precision.

Hvordan fungerer maskinbelter?

3. Injury Prevention The vibrations and jolts experienced while riding can lead to muscle fatigue and injuries such as strains and spasms. A back support belt helps to stabilize the spine and surrounding muscles, reducing the likelihood of such injuries.

Some advanced safety features have emerged over the years, including pretensioners, which tighten the belt upon impact, and load limiters that allow some belt stretch to reduce the risk of chest injuries. In addition, many vehicles come equipped with warning systems that beep or display reminders until all passengers are securely buckled up.

Design Features of the 17450 Model

Regular maintenance is key to prolonging the lifespan of automotive components, including the dynamo belt. Routine inspections and timely replacements can prevent breakdowns and accidents. Mechanics often recommend inspecting the belt at regular intervals, particularly during scheduled service checks or when servicing the engine.

A critical aspect of the revival of the manufacturing belt is the emphasis on innovation. As traditional manufacturing jobs decrease, the demand for skilled workers in advanced manufacturing and technology sectors has increased. This shift highlights the importance of investing in education and upskilling programs to prepare the workforce for the demands of the modern economy. Community colleges and vocational training programs have become essential components in this transformation, equipping individuals with the necessary skills to thrive in a changing landscape.

1. Compact Design The slim profile of a 5PK belt allows for a more compact setup in machinery, enabling manufacturers to save space in their designs.

Supporting Local Economies

4. Lubrication While belts generally require less maintenance, keeping moving parts well-lubricated is vital for reducing friction and wear in the system.

3. Adjust Tension Chains can stretch over time, impacting performance. Check the tension regularly and adjust according to your motorcycle’s specifications to ensure smooth operation.

Conclusion

The significance of the timing belt extends beyond the immediate operation of the engine. A well-maintained timing belt contributes to overall vehicle longevity and performance. When drivers invest in timely maintenance of their timing belts, they not only protect their engine but also enhance vehicle efficiency and safety. It's an essential reminder that in automotive engineering, preventive care can save significant costs and prevent unforeseen failures.

Applications of Flat Belt Transmission

2. Cost-Effectiveness V-belts themselves are relatively inexpensive compared to other power transmission systems, such as chain or gear drives. Their straightforward design also contributes to lower installation and maintenance costs.

Timing belt machines also offer flexibility in design and application. They can be easily integrated into existing systems or customized to meet specific operational needs. Whether it’s for transferring products, automating assembly, or positioning components accurately, timing belts can be adapted to various setups. This versatility makes them a popular choice among engineers and production managers.