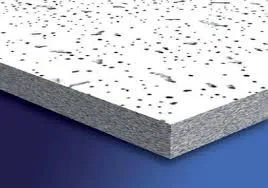

suspended ceiling grid parts

Links

- In conclusion, oil seals play a vital role in the performance and longevity of machinery. By providing a barrier between the internal lubricated parts and the external environment, they prevent the leakage of oil and the entry of contaminants. Choosing the right seal for the application, ensuring compatibility with the oil being used, and performing regular maintenance and inspections are all key factors in maintaining the integrity and effectiveness of these critical components.

-

Figure 5: Shaft surface with and without lead marks

Rotary Wheel Of Auto Parts

The major cause of extrusion and nibbling is stress caused by high pressure. This is commonly noticed when the oil seal has a chipped or nibbled look. In fact, in some cases, the surface of the seal tends to peel on its own, which makes it have a shaved look. What the stress does is that it increases the clearance gap between the mating edges, which causes the seal to get entrapped, and then leads to severe physical damage.

Figure 1: Types of sealing devices

f7tc spark plug. By improving fuel efficiency and reducing emissions, the F7TC Spark Plug helps to reduce our carbon footprint and combat climate change. This makes it an attractive option for consumers who are concerned about their environmental impact and looking for ways to reduce their carbon footprint.

f7tc spark plug. By improving fuel efficiency and reducing emissions, the F7TC Spark Plug helps to reduce our carbon footprint and combat climate change. This makes it an attractive option for consumers who are concerned about their environmental impact and looking for ways to reduce their carbon footprint.