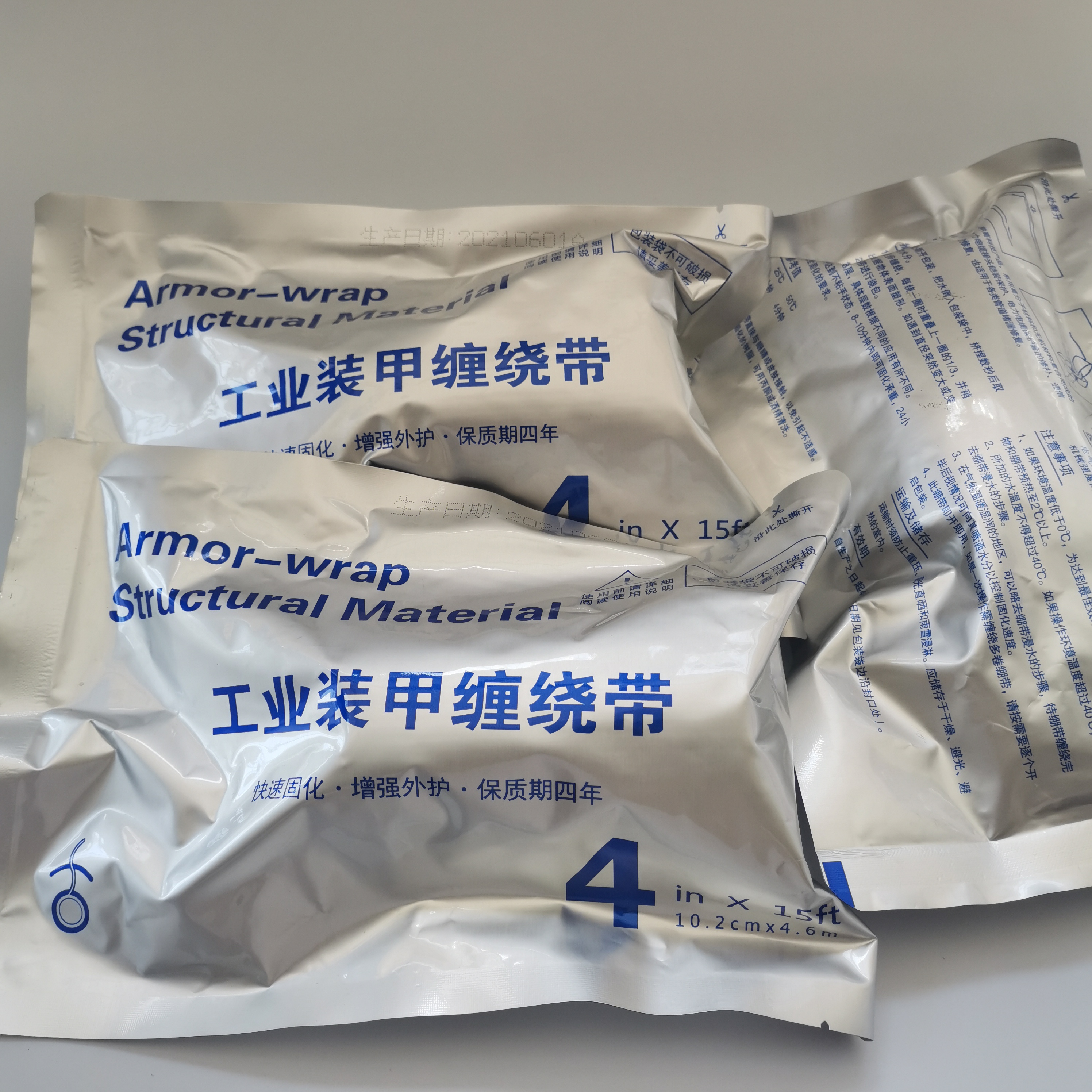

Rubber Adhesives

In conclusion, fire-resistant drywall tape is an essential component in creating safer living and working environments. As regulations become stricter and the focus on safety grows, incorporating fire-resistant materials into building projects is no longer optional; it is imperative. By understanding the benefits and proper application of fire-resistant drywall tape, builders and homeowners alike can contribute to a safer infrastructure, ultimately protecting lives and property from the devastating effects of fire. Whether in residential homes, commercial spaces, or industrial buildings, the choice to use fire-resistant drywall tape is a choice for safety, durability, and peace of mind.