ceiling tile track

Links

- One of the main advantages of thin profile aluminium windows is their ability to provide a large amount of natural light into a space. The thin frames allow for more glass area, which means more sunlight can enter the room. This not only helps to brighten up the space but also creates a more open and airy feel.

Advantages of Using Wrought Iron

Deep Processing

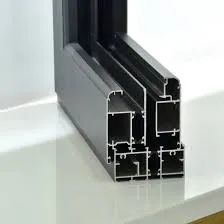

The price of the aluminium windows is directly related to the price of aluminium ingots. Generally, the price of the aluminium windows is relatively stable. The price of the high-quality aluminium windows is usually 30% higher than poor quality aluminium windows. Poor quality aluminium windows usually contains a large amount of inferior and non-compatible materials and their thicknesses are only 0.6-0.8 mm. Hence, when choosing aluminium windows, we should take note of the price and look into their profile and specification to ensure that their thickness and strength meet the relevant national standards.

Another way of looking at a bottom-hung window opening is as a tilt-and-turn but without the turning facility.

Typical aluminum material for windows and doors profiles is often taken through aging process during extrusion. The process strengthens the material, and as temperature reduces, its strength increases.

Wrought iron fence ornaments come in various styles to cater to different tastes and architectural designs. For a classic look, ornate finials, gate decorations, and scrollwork can introduce a sense of traditional elegance. These elements often feature decorative spikes and floral designs, portraying craftsmanship that harks back to centuries of blacksmithing tradition.

Beyond their visual appeal, ornamental cast iron panels offer several practical benefits. They are robust and withstand the test of time, making them ideal for outdoor applications. Unlike materials such as wood or vinyl, cast iron is impervious to rot, pests, and the wear and tear of the elements. This longevity makes it a wise investment for homeowners and developers.

When Should You Choose Wrought Iron?

What is the Difference Between Wrought Iron and Aluminum Fencing?

Another critical factor to consider is the variety of products offered. Wrought iron comes in various shapes, sizes, and finishes, making it essential to find a supplier that provides a comprehensive range of options. Whether you are looking for custom designs, stock items, or specific finishes, a versatile supplier can accommodate your project's unique requirements. Furthermore, a supplier with an extensive inventory can often fulfill orders more rapidly, minimizing delays and keeping projects on schedule.

Repairing screen door rollers is a simple yet effective way to restore functionality to your screen door. With basic tools and a bit of patience, you can enhance your home’s comfort and accessibility. Regular maintenance, including cleaning and lubrication, can prolong the life of your screen door, ensuring that it continues to serve its purpose for years to come.

Once you’ve removed the dirt from your fence, use a stiff wire brush to get rid of any loose paint or rust spots. If that doesn’t do the trick, use some fine sandpaper to remove any remaining rust.

Make sure your fence is completely dry after this step; whether you want to leave it to air dry in the sun or thoroughly dry it with a towel.

The most common component of contemporary wrought iron fences is the tubing made of iron or steel. The tubes are worked into forms by machines, and the manufacturers also utilize devices to produce the decoration traditionally used with a wrought iron fence. The lines are welded together to form wall panels, resulting in a robust iron fence.

Aluminum ornamental iron fencing is becoming the most popular type of fencing especially for residential fencing. Cost is definitely the driving force because aluminum fencing can be manufactured in large quantities at a faster production rate and at a lower cost of production. Aluminum fencing is produced through an extrusion process that basically pushes aluminum blocks of materials through a die system that adheres to the contour of that particular die. Once the piece is formed, the components of the different style of ornamental fencing goes through several steps of priming and powder coating, boxed and ready for shipment from the manufactures to different distributors located throughout the U.S.