mineral fiber acoustic ceiling tiles

-

...

...

...

...

Links

Carved Louis Leaer Mirror Silver

Additionally, frosted glass can be treated in various ways, including sandblasting and acid etching, to achieve the desired level of opacity and design complexity

. This adaptability means that decorative frosted glass can be used in windows, doors, room dividers, and even furniture, integrating seamlessly into many different environments. The score must be precise and firm, creating a defined line where the glass will eventually be separated The score must be precise and firm, creating a defined line where the glass will eventually be separated

The score must be precise and firm, creating a defined line where the glass will eventually be separated The score must be precise and firm, creating a defined line where the glass will eventually be separated 2mm mirror glass cut to size. For 2mm mirror glass, the pressure applied needs to be enough to leave a visible mark without cracking the fragile material.

2mm mirror glass cut to size. For 2mm mirror glass, the pressure applied needs to be enough to leave a visible mark without cracking the fragile material. A partially silvered mirror, also known as a beam splitter, serves as a fascinating interface between light and reflection. This optical device enhances our understanding of light behavior and plays an essential role in various fields, including photography, optical instruments, and experimental physics.

In the ever-evolving landscape of architectural design and construction, tinted tempered glass stands out for its combination of strength, efficiency, and beauty. As sustainability becomes a priority, the demand for this versatile glass is likely to grow, making it a preferred choice for future constructions. Whether in homes, offices, or vehicles, tinted tempered glass offers an optimal blend of performance and style, contributing to safer and more energy-efficient environments.

In conclusion, heat mirror glass represents a significant advancement in the field of building materials. Combining energy efficiency, environmental benefits, UV protection, aesthetic versatility, and durability, it offers a holistic solution for modern construction. As more builders, architects, and homeowners recognize the advantages of this technology, heat mirror glass is poised to become a standard component in the pursuit of sustainability and comfort in our built environments. Embracing this innovative material not only leads to cost savings and environmental responsibility but also fosters a more enjoyable indoor living and working experience.

In conclusion, brown mirror glass is more than just a reflective surface; it is a statement of style and sophistication. Whether in a residential or commercial setting, its ability to enhance visual appeal, create warm atmospheres, and provide practicality makes it a cherished choice in contemporary design. As we move forward into a new era of architectural and interior design, one thing is clear the allure of brown mirror glass is here to stay.

Its high solar reflectance helps in reducing heat absorption, making it an ideal choice for energy-efficient buildings Its high solar reflectance helps in reducing heat absorption, making it an ideal choice for energy-efficient buildings

Its high solar reflectance helps in reducing heat absorption, making it an ideal choice for energy-efficient buildings Its high solar reflectance helps in reducing heat absorption, making it an ideal choice for energy-efficient buildings black float glass. Its low emissivity further enhances its insulation capabilities, contributing to a more comfortable indoor environment.

black float glass. Its low emissivity further enhances its insulation capabilities, contributing to a more comfortable indoor environment. Understanding Low-E Glass The Modern Solution for Energy Efficiency

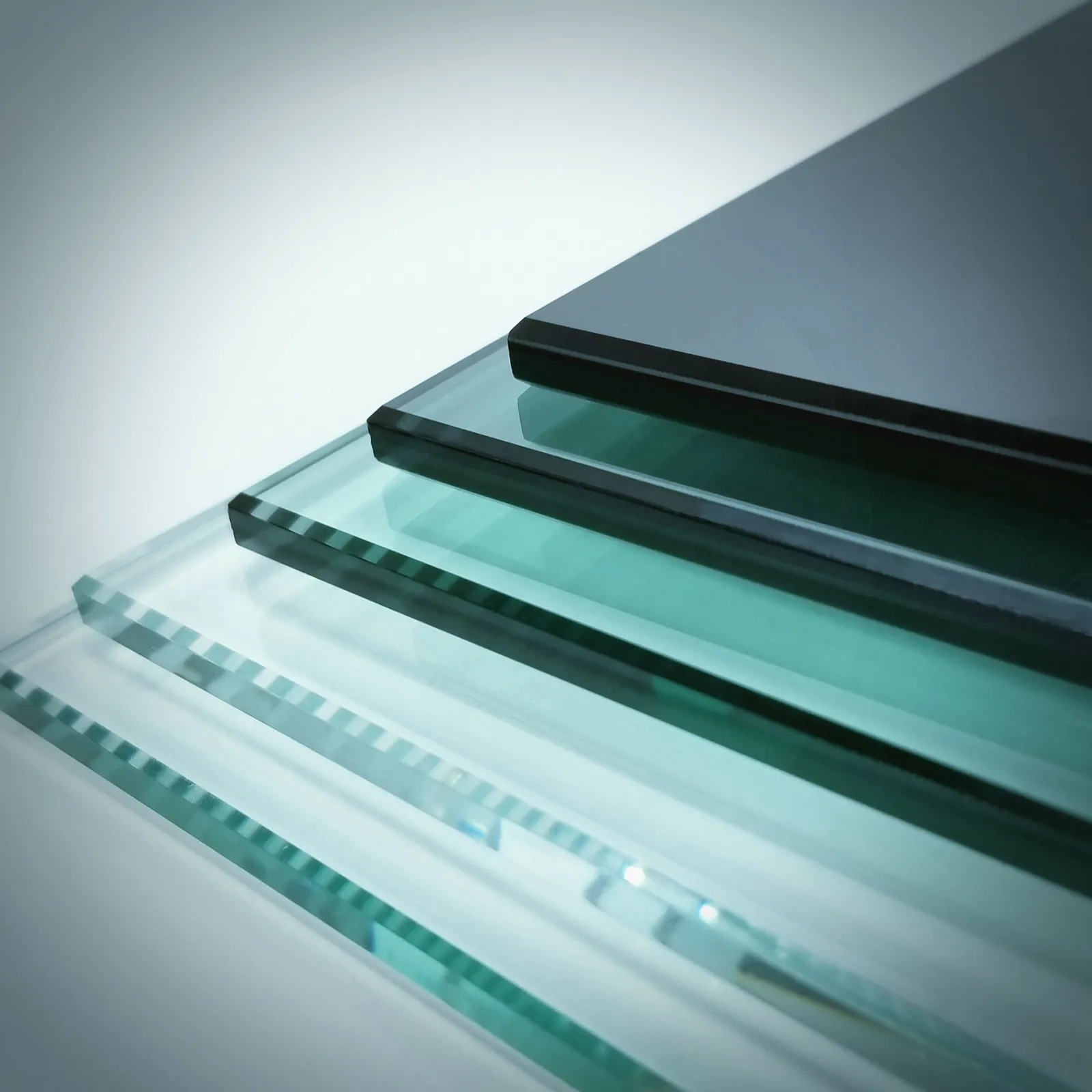

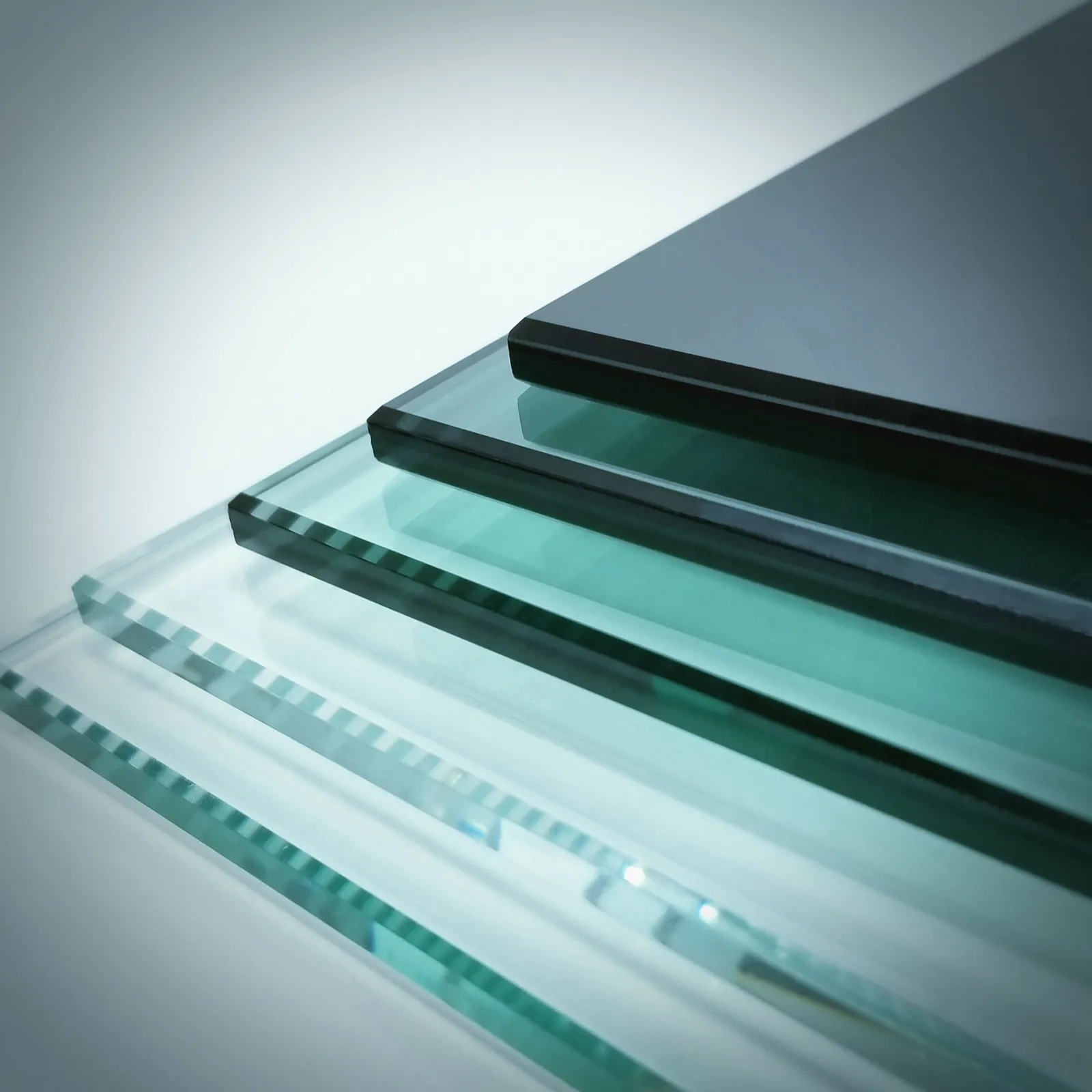

Tempered glass manufacturers are at the forefront of innovation, continuously improving their production techniques and technologies. State-of-the-art manufacturing facilities now incorporate automated cutting, precise heating, and cooling technologies that enhance efficiency and safety. Furthermore, advancements in coating technologies allow manufacturers to produce tempered glass with specific properties, such as increased thermal insulation, UV resistance, or anti-reflective surfaces. These innovations not only improve the product's structural integrity but also enhance aesthetic appeal, making tempered glass an exquisite choice for modern architectural designs.

Ultra clear glass finds its application across various sectors. In architecture and construction, it is frequently used for facades, windows, and balustrades, allowing bright, natural light to flood interior spaces. In the retail industry, it serves as high-quality display cases that accentuate merchandise without distorting colors.

One of the main reasons why floral pattern glass is so beloved is its timeless appeal. The intricate floral designs on the glass create a sense of beauty and sophistication that never goes out of style. Whether you prefer a more traditional look or a modern aesthetic, floral pattern glass can effortlessly blend into any decor style.

They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws

They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws They understand that the thinness of the glass demands a meticulous production process to prevent breakage and flaws 2mm float glass supplier. As such, they employ stringent quality control measures from the melting phase to the packing stage, ensuring each sheet delivered to clients is free from waves, bubbles, and distortions.

2mm float glass supplier. As such, they employ stringent quality control measures from the melting phase to the packing stage, ensuring each sheet delivered to clients is free from waves, bubbles, and distortions.  He discovered that the mirror was not just a reflection of the physical world but also a window into the spiritual realm, where the souls of the departed resided He discovered that the mirror was not just a reflection of the physical world but also a window into the spiritual realm, where the souls of the departed resided

He discovered that the mirror was not just a reflection of the physical world but also a window into the spiritual realm, where the souls of the departed resided He discovered that the mirror was not just a reflection of the physical world but also a window into the spiritual realm, where the souls of the departed resided arch mirror silver.

arch mirror silver.

Some say it is the work of fairies, others believe it is the product of ancient magic Some say it is the work of fairies, others believe it is the product of ancient magic

Some say it is the work of fairies, others believe it is the product of ancient magic Some say it is the work of fairies, others believe it is the product of ancient magic silver bubble mirror. But one thing is for certain the Silver Bubble Mirror holds a power that goes beyond the mere act of reflection.

silver bubble mirror. But one thing is for certain the Silver Bubble Mirror holds a power that goes beyond the mere act of reflection.

Any imperfections or blemishes are carefully addressed by the skilled artisans at the factory, who work tirelessly to ensure that every piece of patterned glass that leaves the facility is flawless Any imperfections or blemishes are carefully addressed by the skilled artisans at the factory, who work tirelessly to ensure that every piece of patterned glass that leaves the facility is flawless

Any imperfections or blemishes are carefully addressed by the skilled artisans at the factory, who work tirelessly to ensure that every piece of patterned glass that leaves the facility is flawless Any imperfections or blemishes are carefully addressed by the skilled artisans at the factory, who work tirelessly to ensure that every piece of patterned glass that leaves the facility is flawless patterned glass factory.

patterned glass factory. (1) Glass installation

Custom acid etched glass is a popular choice for adding a touch of elegance and uniqueness to any space. This technique involves using acid to create intricate designs on the surface of the glass, resulting in a frosted, translucent finish that is both beautiful and practical.

This makes frosted pink glass an ideal choice for creating a cozy reading nook, a romantic dining area, or a feminine bedroom This makes frosted pink glass an ideal choice for creating a cozy reading nook, a romantic dining area, or a feminine bedroom

This makes frosted pink glass an ideal choice for creating a cozy reading nook, a romantic dining area, or a feminine bedroom This makes frosted pink glass an ideal choice for creating a cozy reading nook, a romantic dining area, or a feminine bedroom frosted pink glass.

frosted pink glass. The performance of IGU glass extends beyond thermal insulation. It also plays a critical role in sound attenuation. Buildings located in noisy urban environments can benefit greatly from using IGUs, as the multiple layers of glass act as a barrier, significantly reducing the penetration of external noise. This feature is particularly valuable for residential buildings near busy roads, schools, or commercial areas, allowing occupants to enjoy peace and quiet within their living spaces.