ceiling grid

Links

- The use of cloth for this type of tape is not arbitrary; it's chosen for its strength and ability to withstand the wear and tear of everyday use. The weave of the cloth allows the tape to be flexible but durable, making it ideal for wrapping around uneven surfaces or sharp corners without tearing. Additionally, the porous nature of the fabric enables it to breathe, which is crucial in preventing the build-up of heat that could otherwise degrade the insulation over time.

-

It’s important to consider the specific requirements of the application, including temperature range, mechanical stress, chemical exposure, electrical properties, and budget when selecting the most suitable carrier material for adhesive tapes. Each material has its advantages and is chosen based on the specific demands of the application.

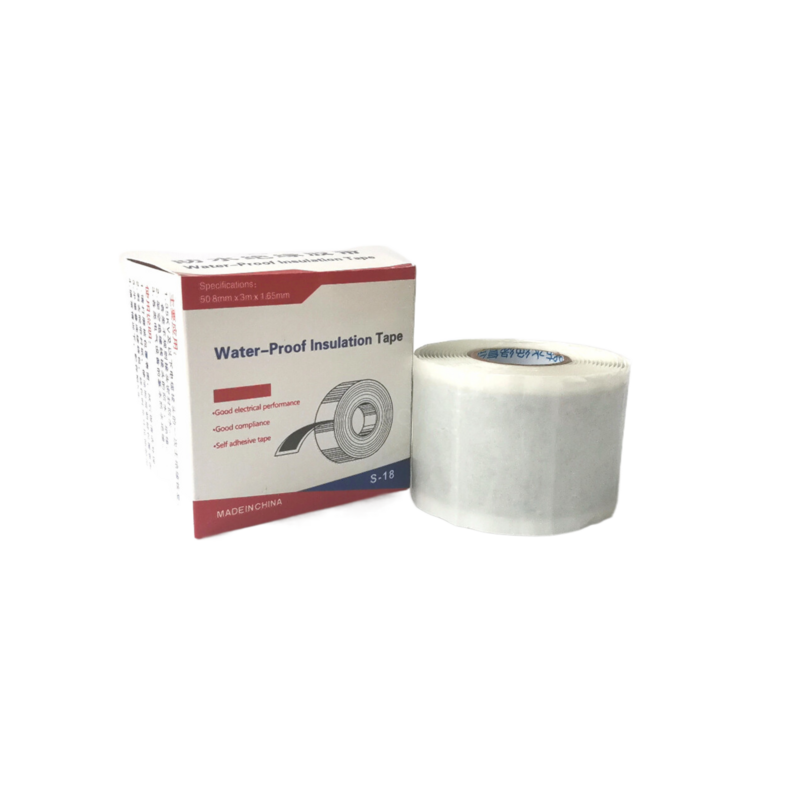

- Consisting of a thin, durable, and flexible insulating material coated with an adhesive backing, high-voltage insulation tape offers excellent dielectric strength and breakdown voltage ratings, ensuring it can withstand high levels of electrical stress without breaking down or allowing current to pass through. This makes it particularly well-suited for use in high-voltage environments where conductors are closely spaced or subjected to mechanical stress.

- Blue insulation tape is a type of electrical tape that is specifically designed to insulate wires and cables. It is made from high-quality materials that are resistant to heat, moisture, and chemicals, making it ideal for use in a variety of environments. The blue color of the tape is also an important visual cue, as it helps to distinguish it from other types of tapes that may be used in electrical work.

-

When you think of types of electrical tape, you probably imagine it in black. However, manufacturers produce electrical insulation tape in almost every color of the rainbow. The varying colors indicate voltage protection and insulation. It’s vital to use the right colored tape—an incorrect tape color puts technicians at risk of insufficient voltage shielding:

- Moreover, rubber tape is not just a repair solution; it is also a preventive measure. Applying it to threads before installation can prevent leaks from occurring in the first place, particularly in high-pressure systems where even the slightest gap can lead to significant problems.

- In the world of piping and hydraulic systems, vulcanizing tape is a go-to tool. It's commonly used to seal pipe joints, preventing leaks and ensuring the integrity of the system. Its resistance to high pressures and temperatures makes it ideal for use in harsh environments, such as oil rigs or chemical processing plants. Furthermore, its ability to maintain its sealing properties over time ensures long-term reliability, reducing maintenance costs and potential downtime.

- It is a non-tacky silicone-rubber tape that is used for adhesion or protection of materials. Rubber tapes are used in many areas like providing protection and electrical insulation layer for different equipment like cables and electrical joints. Rubber tape is resistant to heat, weather and sunlight. In solar module manufacturing, it is widely used as a sealant due to its mainly good mechanical properties, impact resistance, high adhesion properties, and relatively cheap cost. It is used during manufacturing, installation and normal operation of PV modules for mounting, adhesion and sealing requirements for modules. Advantages and disadvantages of using rubber tape edge sealant Rubber sealing tape meets the demand of a wide variety of difficult sealing applications. It can be used for oversealing of an existing joint or penetration, normal sealing applications which are typically done with a gasket, or liquid sealant/adhesive. The rubber sealant tape is flexible, durable, and abrasion resistant. It is also conformable which helps create an effective seal over contours, edges rivets, and edges. Rubber tape also has good moisture resistance and as an edge sealant primarily prevents moisture ingress and protects components besides insulation splices and connections in electrical components. The rubber tape is susceptible to cuts and abrasion as it has low tear resistance. This disadvantage is increased because the rubber tape is wrapped while stretched, and stays under internal tension. Yet, these same properties, make tape removal when needed clean and easy.

vulcanizing tape. The tape will adhere to itself and create a tight, secure bond that is resistant to moisture and corrosion.

5. Allow the tape to cure Once wrapped, let the tape sit for a few minutes to allow it to cure and create a strong bond. Depending on the type of tape, it may take anywhere from a few minutes to a few hours to fully cure.

Butyl Rubber Tape

Moreover, butyl rubber tape is non-toxic and safe for use in various applications, including food-related contexts. This makes it a great choice for sealing appliances, packaging, or other areas where food safety is a concern. Its versatility extends to a range of industries, including automotive, construction, electronics, and more.

diall self fusing tape. Its high dielectric strength makes it safe to use on electrical components, providing an extra layer of protection against shorts and sparks. The flexibility of the tape allows for easy wrapping around irregular shapes and surfaces.

Understanding 3M HT Insulation Tape A Versatile Solution for Various Applications

Inline splice insulation. You can protect a low-voltage inline splice in a similar manner by wrapping the installed connector with four half-lapped layers of rubber mastic tape or rubber splicing tape, and then over-wrapping it with two half-lapped layers of premium vinyl electrical tape.

Conclusion

It requires an understanding of the warehouse's workflow, storage systems, and safety protocols It requires an understanding of the warehouse's workflow, storage systems, and safety protocols

It requires an understanding of the warehouse's workflow, storage systems, and safety protocols It requires an understanding of the warehouse's workflow, storage systems, and safety protocols warehouse floor tape. Installers must ensure that the tape is applied evenly and securely to the floor to withstand the heavy foot and vehicle traffic without peeling or curling at the edges. The choice of material for the tape is also critical; it must be durable enough to endure the constant wear and tear yet flexible enough not to crack under pressure or temperature changes.

warehouse floor tape. Installers must ensure that the tape is applied evenly and securely to the floor to withstand the heavy foot and vehicle traffic without peeling or curling at the edges. The choice of material for the tape is also critical; it must be durable enough to endure the constant wear and tear yet flexible enough not to crack under pressure or temperature changes. Another type of splicing tape is the magnetic tape. This tape is used in the editing process to align audio tracks with visual footage. By using magnetic splicing tape, editors can synchronize sound effects, music, and dialogue with the corresponding scenes, creating a cohesive and engaging film soundtrack.

splicing tape

High voltage busbar insulation tape is specifically designed to withstand elevated voltage conditions. It serves as a barrier that isolates electrical conductors and protects against external factors such as moisture, dust, and chemical exposure.

Black Flex Tape is a thick, rubberized tape designed for a wide range of uses. It is waterproof, strong, and adheres to almost any surface, making it an ideal choice for both indoor and outdoor repairs. The tape is often marketed as being able to seal, bond, and repair almost anything, from leaks in pipes to cracks in car windshields. With its easy-to-use application and robust performance, it offers a quick fix for emergencies, reducing the time and effort typically involved in repair work.

It also has a low flammability rating, which makes it safer to use in buildings and other structures It also has a low flammability rating, which makes it safer to use in buildings and other structures

It also has a low flammability rating, which makes it safer to use in buildings and other structures It also has a low flammability rating, which makes it safer to use in buildings and other structures pvc electrical insulation. Additionally, PVC insulation is relatively inexpensive compared to other insulating materials, making it a cost-effective option for many electrical applications.

pvc electrical insulation. Additionally, PVC insulation is relatively inexpensive compared to other insulating materials, making it a cost-effective option for many electrical applications.  For instance, red tape can be used to highlight promotions or sales, or to create eye-catching displays on the floor For instance, red tape can be used to highlight promotions or sales, or to create eye-catching displays on the floor

For instance, red tape can be used to highlight promotions or sales, or to create eye-catching displays on the floor For instance, red tape can be used to highlight promotions or sales, or to create eye-catching displays on the floor red floor tape. This can attract customers' attention and drive foot traffic, ultimately boosting sales and increasing brand visibility.

red floor tape. This can attract customers' attention and drive foot traffic, ultimately boosting sales and increasing brand visibility. Benefits of Using Butyl Rubber Rolls

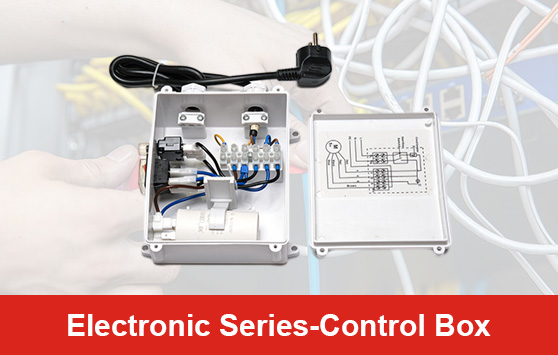

However, if you do intend to build your own well pump control box, make sure you’ve got well pump wiring diagrams on hand, as well as the technical specs of the pump you’re using. It’s common to install a well pump control device in an outdoor electrical box , and if that’s part of your plan, make sure to invest in an outdoor enclosure .