suspended ceiling grid cost per m2

-

...

...

...

...

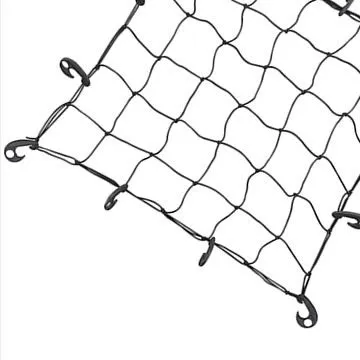

By using T-bar brackets, installers can create a level and even surface, which is essential for aesthetic appeal and effective acoustics within a room. Proper installation of these brackets is crucial, as any imbalance can lead to sagging or uneven ceilings.

5. Low Maintenance One of the standout features of PVC gypsum tiles is their low maintenance requirements. Unlike porous materials that require regular sealing and treatment, PVC tiles can be easily cleaned with a damp cloth, making upkeep straightforward and hassle-free.

Understanding the T runner ceiling encompasses a blend of physiological, psychological, and environmental factors that all contribute to an athlete's performance. While running is an impressive display of human potential, it is crucial to acknowledge that every athlete has a ceiling defined by their unique limitations and capabilities.

2. Acoustics One of the primary functions of a ceiling grid system is to manage acoustics within a room. The tiles can be chosen for their sound-absorbing qualities, which is particularly important in environments such as open-plan offices or auditoriums where noise control is crucial. By selecting appropriate materials, designers can significantly reduce echo and background noise, creating more comfortable environments.

Benefits of T-Bar Suspended Ceiling Grids

3. Framing the Opening For larger hatches and in instances where additional support is needed, framing with wooden studs may be necessary to provide a sturdy base for the hatch.

Benefits of Ceiling T Bars

4. Air Quality Benefits Many mineral fiber ceiling products are designed to improve indoor air quality. They often feature surfaces that resist dust and mold growth, helping to create a healthier environment. Some products even include anti-microbial properties, further enhancing their suitability for spaces like healthcare facilities or schools.

Understanding Grid Covers

There are several types of drop ceiling access panels available on the market, each suited to specific applications

Links

The construction of an oil seal is a testament to meticulous engineering. Each oil seal primarily comprises two core components: the sealing element and the metal case. The collaboration of these parts brings about the seal’s functionality and effectiveness. A garter spring may also be included as an available feature, providing an extra layer of operational support.

A patent for an oil seal was filed by Nelson Thomas Edward on August 12, 1937, and published a year later. There were two purposes described. The device was to provide an oil seal between a fixed housing and a rotating part. The seal is described as

Foam inhibitors: This additive does exactly what it sounds like. Foam inhibitors keep motor oil from forming foam and bubbles. If foam and bubbles were to form, the oil would be unable to coat the important parts of the engine and keep it cool.

Table 1: The functions of the various components

Pressure - Many oil seals can only withstand low-pressure applications, so understanding the compression set of your components is key.

5, the oil seal is easy to dismantle and inspection is convenient.

boat spark plugs. Boat spark plugs with platinum or iridium also offer improved durability and longevity. These premium materials are much harder than conventional copper or nickel spark plugs, which means they can withstand the rigors of marine use without wearing out as quickly. This translates to fewer replacements and lower overall maintenance costs.

boat spark plugs. Boat spark plugs with platinum or iridium also offer improved durability and longevity. These premium materials are much harder than conventional copper or nickel spark plugs, which means they can withstand the rigors of marine use without wearing out as quickly. This translates to fewer replacements and lower overall maintenance costs.  boat spark plugs. Boat spark plugs with platinum or iridium also offer improved durability and longevity. These premium materials are much harder than conventional copper or nickel spark plugs, which means they can withstand the rigors of marine use without wearing out as quickly. This translates to fewer replacements and lower overall maintenance costs.

boat spark plugs. Boat spark plugs with platinum or iridium also offer improved durability and longevity. These premium materials are much harder than conventional copper or nickel spark plugs, which means they can withstand the rigors of marine use without wearing out as quickly. This translates to fewer replacements and lower overall maintenance costs.

Table 4: JTEKT oil seal type codes and corresponding ISO and JIS standards

Lever the seal out with a screwdriver, working carefully to avoid scoring the seal housing.

When selecting oil seals for automotive and industrial use, it's essential to consider factors such as compatibility, durability, and performance specifications. The seals should be designed to withstand the specific operating conditions and environmental factors they will encounter. Additionally, choosing reputable suppliers and manufacturers known for producing high-quality oil seals is crucial to ensure the reliability and longevity of the components.

PTFE, which is used in the well-known brand Teflon®, is less commonly used, but it is the preferred material for specific rotating seals in the chemical, food and pharmaceutical industries. This material is notable for having a very low frictional resistance and the best chemical resistance. It can also withstand a very wide range of temperatures in these types of seals; -80 ˚C to 200 ˚C. The shafts on which oil seals with PTFE lips are used require a harder and finer finish. Something like an axle sleeve can also be used to meet this requirement.

Oil seals or shaft seals are an integral part in any rotating and moving part assembly. Oil seals find great deal of usage in gearboxes, hydraulic cylinders, etc. The usage of the seals in areas concerned with motion also earns them a name of “Dynamic Oil Seals.”

Several variables must be considered when selecting oil seals. The physical dimensions and materials will vary depending on the environment of use. In addition, oil seals must remain lightweight, compact, and exhibit high self-lubrication performance.