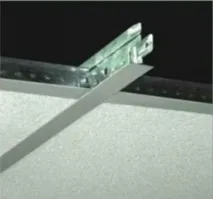

ceiling access door

In modern homes, ceiling trap doors continue to be valued for their practicality. They are often installed as access points to attic spaces, enabling homeowners to store seasonal items, holiday decorations, or excess belongings out of sight. This clever use of vertical space not only keeps homes organized but also contributes to efficient heating and cooling, as unused attics can act as insulation zones.

These gaskets are used in a variety of plumbing fittings, such as couplings, elbows, and tees, providing a leak-proof connection that prevents water damage and mold growth These gaskets are used in a variety of plumbing fittings, such as couplings, elbows, and tees, providing a leak-proof connection that prevents water damage and mold growth

These gaskets are used in a variety of plumbing fittings, such as couplings, elbows, and tees, providing a leak-proof connection that prevents water damage and mold growth These gaskets are used in a variety of plumbing fittings, such as couplings, elbows, and tees, providing a leak-proof connection that prevents water damage and mold growth