laminated ceiling board

-

One of the most significant advantages of using a tee bar ceiling grid is its flexibility. Designers can customize the layout easily, allowing for various shapes and sizes to fit the specific needs of a space. This adaptability also enables the installation of different ceiling tiles, from acoustic panels to decorative designs, thereby enhancing the overall aesthetic of the environment.

...

Links

In a review published in 2022 in the journal Archives of Toxicology, researchers found that the ingestion of E171 is a “a definite health risk for consumers and their progeny.” After reviewing dozens of in vivo, ex vivo and in vitro studies on the toxicity of E171, the researchers wrote that two facts must be noted: “First, reprotoxicity studies show that animals of both sexes are impacted by the toxicity of these nanoparticles, underlining the importance of conducting in vivo studies using both male and female animals. Second, human exposure begins in utero via maternal-fetal transfer and continues after birth by breastfeeding. Children are then chronically re-exposed due to their food preferences. To be relevant to the human in vivo situation, experimental studies should therefore consider nanoparticle exposure with respect to the age or life period of the studied population.”

Europe

So, what does it all mean for you, the consumer? Should you stop eating Skittles or begin checking foods for the presence of titanium dioxide? Here's a closer look.

Partial substitution of titanium dioxide in liquid paints

On the other hand, some of the top manufacturers of titanium dioxide include Chemours, Tronox, and Kronos

. These companies have advanced chemical processing facilities that can produce high-quality titanium dioxide for various applications.

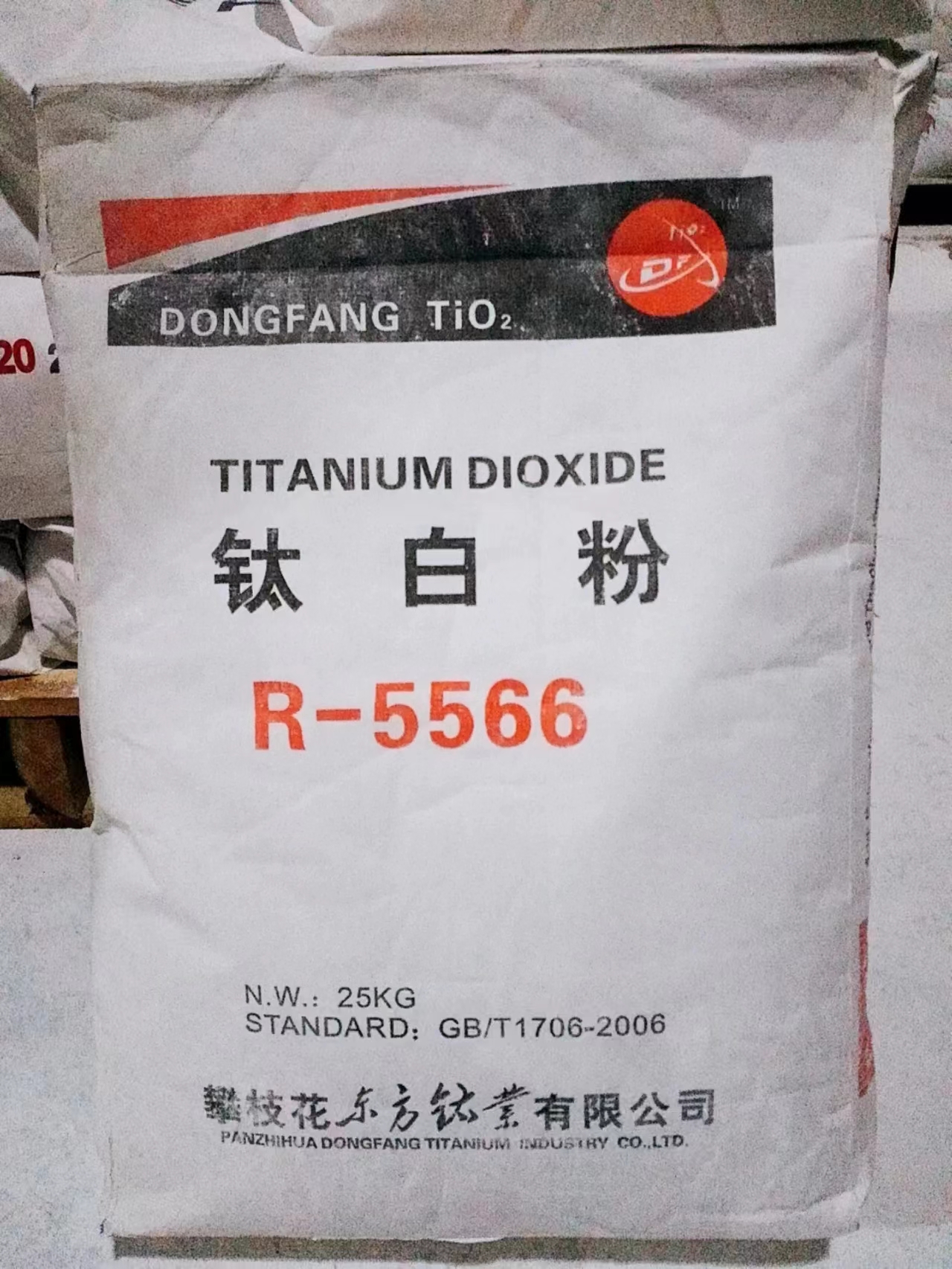

Package:

25KG/50KG Woven bag with inner, or 1000kg big woven plastic bag.

Company Information

Loman Chemical Group (include Shanghai Loman Chemical Co Ltd; Wuhu Loman Chemical Co Ltd and Wuhu Loman Titanium Industial Co Ltd.)is one of the main titanium dioxide manufacturers in china, producing various high quality Anatase and Rutile titanium dioxide. Loman brand products, has being widely used in paper, paint, plastic, ink, coating, rubber, cosmetic, food, fiber, etc.

In order to meet different requirements of various customers, we actively expand producing other pigments, include Lithopone, Barium sulfate and Silica. Annual production volume of anatase and rutile grade titanium dioxide have reached 100,000 tons, lithopone 30.000 tons, barium sulfate 50.000 tons and precipitated silica 8.000 tons. The Loman brand is one of the famous brands in China, having great popularity both at home and abroad. Our products have been widely used in European, North America and Southeast Asia.

Our advantages:

1)With the most professional manufacturers,High quality and high safety product

2)Professional consulting services are availabe for you at antyime

3)Have a favorable price ,reliable quality

4)Complete products meet your purchasing need

Barium sulphate, a chemical compound with the formula BaSO₄, is widely recognized for its numerous applications in various industries, particularly in the field of medicine, paints, plastics, and as a component in drilling fluids. One of the distinguishing features of barium sulphate is its striking physical property its color. Understanding the color of barium sulphate not only helps in identifying the compound during handling but also plays a significant role in its applications and quality assessment.

China’s TiO2 exports were booming in 2016. The continuously depreciating RMB and the increasing export scales of China’s manufacturers have strengthened this development throughout the year. As a fact, many of China’s producers exported their products with a lower price while achieving higher profit margins in the domestic market of TiO2. Tranalysis, a trade analysis provider, now reveals the top 10 Chinese TiO2 exporters of the year 2016 with the original data of China Customs.

We know that there are a lot of suspended organisms and colloidal impurities in natural water. The forms of suspended solids are different. Some large particles of suspended solids can settle under their own gravity. The other is colloidal particles, which is an important reason for the turbidity of water. Colloidal particles can not be removed by natural settlement, because colloidal particles in water are mainly clay with negative electricity The Brownian motion of colloidal particles and the hydration on the surface of colloidal particles make colloidal particles have dispersion stability. Among them, electrostatic repulsion has the greatest influence. If coagulant is added to water, it can provide a large number of positive ions and accelerate the coagulation and precipitation of colloid. Compressing the diffusion layer of micelles makes the potential change into an unstable factor, which is also conducive to the adsorption and condensation of micelles. The water molecules in the hydrated film have fixed contact with the colloidal particles and have high elastic viscosity. It is necessary to overcome the special resistance to expel these water molecules. This resistance hinders the direct contact of the colloidal particles. The existence of some hydrated films depends on the electric double layer state. If coagulant is added to reduce the zeta potential, the hydration may be weakened. The polymer materials formed after coagulant hydrolysis (the polymer materials directly added into water generally have chain structure) play an adsorption bridging role between the colloidal particles. Even if the zeta potential does not decrease or does not decrease much, the colloidal particles can not contact each other and can be adsorbed through the polymer chain Colloidal particles can also form flocs.

Titanium dioxide, or TiO2, sometimes referred to as E171, is an inorganic, solid substance used in a wide range of consumer goods including cosmetics, paint, plastic and food, according to the American Chemistry Council.

Source: Tranalysis and China Customs

Dispersion in the polymer: optimum dispersion should produce a good distribution and separation of titanium dioxide particles in the formulation.