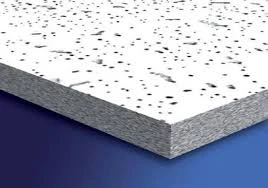

laminated gypsum ceiling board

Conclusion

Applications of Mineral Fiber Ceilings

A ceiling access panel serves as a gateway to hidden spaces within ceilings, enabling easy access to plumbing, electrical systems, ductwork, and other critical infrastructure. The 24” x 24” size is particularly advantageous because it strikes a balance between providing ample access and maintaining structural integrity. Whether in a home, office, or commercial building, having a reliable access point can save time and money during maintenance and repairs.

5. Finishing Touches After the hatch is installed, tape and mud the edges to blend it into the surrounding drywall, making it less noticeable.

Links

- In the food industry, MHEC is approved as a food additive, E461. It functions as a stabilizer, emulsifier, and thickener in various food products, including ice cream, salad dressings, and baked goods. It improves the texture and extends the shelf life of these products.

- Overall, HPMC is a versatile and multi-functional ingredient that is widely used in various industries. Its unique properties make it an essential component in the formulation of a wide range of products. Whether it is used as a thickening agent, film-forming agent, emulsifier, or stabilizer, HPMC provides numerous benefits and enhances the quality of the final product.

- Another benefit of using HEC is its compatibility with other ingredients

hydroxyethyl cellulose viscosity concentration.

hpmc chemical structure.

In pharmaceuticals, MHEC is used as a controlled-release excipient, and manufacturers must adhere to stringent regulations to ensure purity and safety In pharmaceuticals, MHEC is used as a controlled-release excipient, and manufacturers must adhere to stringent regulations to ensure purity and safety

In pharmaceuticals, MHEC is used as a controlled-release excipient, and manufacturers must adhere to stringent regulations to ensure purity and safety In pharmaceuticals, MHEC is used as a controlled-release excipient, and manufacturers must adhere to stringent regulations to ensure purity and safety methyl hydroxyethyl cellulose manufacturers. Cosmetics and personal care industries also rely on MHEC for its emulsifying and film-forming properties in products like lotions and hair care treatments.

methyl hydroxyethyl cellulose manufacturers. Cosmetics and personal care industries also rely on MHEC for its emulsifying and film-forming properties in products like lotions and hair care treatments.

HPMC in capsules and in the coating of tablets

It remains soluble over a wide pH range, making it applicable in both acidic and alkaline environments It remains soluble over a wide pH range, making it applicable in both acidic and alkaline environments

It remains soluble over a wide pH range, making it applicable in both acidic and alkaline environments It remains soluble over a wide pH range, making it applicable in both acidic and alkaline environments hydroxypropyl methyl cellulose solubility. However, at extreme pH levels, degradation or precipitation may occur.

hydroxypropyl methyl cellulose solubility. However, at extreme pH levels, degradation or precipitation may occur.