ceiling tees

-

...

...

Links

Functional Applications

HPMC (Hidroliz edilmiş Poli (metil metakrilat)) polymeri, müasir materiallar sahəsində geniş istifadə olunan mühüm bir polimerdir. Bu polymer, xüsusilə ticari və sənaye tətbiqlərində öz sahələrini genişləndirmək üçün diaqnostik və konstruktiv xüsusi xüsusiyyətlərə malikdir. HPMC, celluloza əsaslı bir maddədir və kimyəvi modifikasiya edilməsi nəticəsində suyun tərkibində asanlıqla həll olur. Bu, onun bir çox sektorda tətbiqini asanlaşdırır.

The manufacturing of redispersible polymer powders involves several key steps. Initially, the polymer is created in an emulsion form. This process requires precise control of conditions like temperature and pH to achieve the desired properties in the final product. Once the emulsion has been produced, it is subjected to a spray-drying process, where the water is evaporated, and a powder is formed. Careful attention during this process ensures that the properties of the polymer are preserved, ensuring that when the powder is later redispersed, it functions effectively in its applications.

- Molecular Weight The molecular weight of HPMC also plays a significant role. Higher molecular weight HPMC tends to have lower solubility due to greater entanglement and intermolecular cohesion.

Hydroxyethyl cellulose can dissolve in both cold water and hot water, but hot water can accelerate the dissolution process. Generally speaking, it is more appropriate to adjust the water temperature between 40 ° C and 70 ° C. Excessive water temperature may lead to HEC degradation, while excessively low water temperature may slow down the dissolution rate.

In the food industry, HPMC is commonly used as a thickening, emulsifying, and stabilizing agent. Its ability to retain moisture and improve texture makes it a popular ingredient in various food products, including baked goods, sauces, and salad dressings. HPMC is also recognized as a food additive (E464), appealing to food manufacturers looking for plant-based alternatives to traditional emulsifiers and stabilizers. Its low-calorie content makes it an attractive option for creating low-fat and gluten-free products, contributing to healthier food choices for consumers.

In conclusion, HPMC's solubility in water is a defining characteristic that enhances its utility across various sectors. From pharmaceuticals to food and construction, understanding the factors that influence this solubility can lead to the development of more effective products and formulations. As research continues, the potential applications of HPMC are likely to expand, making it an essential component in both existing and emerging industries. Its unique properties underline its importance, ensuring that HPMC remains a topic of interest for scientists, formulators, and manufacturers alike.

近年、建築業界ではさまざまな材料が使用され、特にモルタル接着剤はその重要性を増しています。モルタル接着剤は、セメント、砂、水などの成分から構成され、主にブロック、タイル、石材などの接着に使用されます。この記事では、モルタル接着剤の特性や利点について解説します。

Given its unique properties, HPMC finds applications in various sectors. In the pharmaceutical industry, it functions as an excipient in tablet formulations and as a thickener in liquid medications. In the food industry, it serves as a food additive, improving texture and shelf-life. Additionally, in the construction sector, HPMC is used as a water-retaining agent in mortars and concrete, enhancing workability and adhesion.

3. Improved Adhesion HPMC enhances the bonding strength of tile adhesives. The polymer forms a cohesive film that helps tiles adhere firmly to the substrate. The improved adhesion is particularly beneficial in environments subject to moisture fluctuations, such as bathrooms and kitchens.

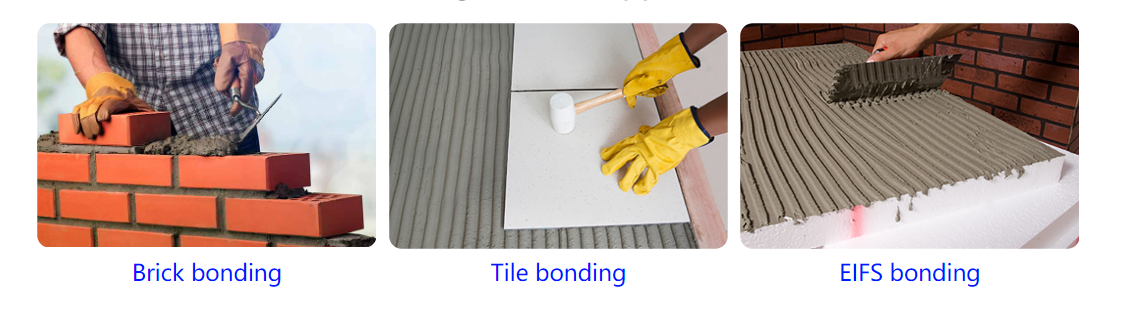

Redispersible powder polymers (RDPs) are innovative additives that play a crucial role in enhancing the performance of construction materials. These fine, free-flowing powders are widely used in the formulation of dry-mix products such as tile adhesives, wall putties, and external insulation systems. Their ability to improve various properties of construction materials has made them indispensable in modern building practices.

Methyl Hydroxyethyl Cellulose (MHEC) is an important cellulose derivative widely used in various industries due to its unique properties

. As a non-ionic, water-soluble polymer, MHEC has gained popularity for its applications in construction, pharmaceuticals, cosmetics, and food products. The manufacturing process for MHEC requires precision and expertise, making reputable manufacturers crucial for ensuring quality and consistency.Environmental Considerations

Em resumo, a utilização de HPMC no pó de massa oferece uma série de benefícios que vão desde a melhora na aplicabilidade até a manutenção da qualidade e durabilidade do produto final. Com sua capacidade de retenção de água, fácil preparação, propriedades de espessamento e perfil de segurança, o HPMC se destaca como um aditivo invaluable na indústria da construção, promovendo não apenas a eficiência, mas também a sustentabilidade em projetos de construção civil. Portanto, incorporar HPMC nas formulações de pó de massa é uma decisão estratégica para profissionais do setor que buscam qualidade e inovação em seus produtos.

Hydroxypropyl Methylcellulose (HPMC) is a versatile and widely used cellulose derivative that plays a crucial role in various industries, including pharmaceuticals, food, cosmetics, and construction. This article explores what HPMC is, its properties, applications, and significance in contemporary manufacturing processes.

Die Kombination von VAEs und RNNs eröffnet interessante Möglichkeiten für innovative Anwendungen. Ein Beispiel hierfür ist die Generierung von Texten, bei der ein VAE genutzt wird, um die Struktur und die Stilistik bestehender Texte zu erlernen, während das RNN die Fähigkeit hat, sprachliche Kontinuität und Kohärenz in den generierten Texten aufrechtzuerhalten. Dadurch können realistische und zusammenhängende Texte erzeugt werden, die jedoch nicht direkt aus den ursprünglichen Trainingsdaten stammen.

In the cosmetics and personal care industry, HPMC is valued for its emulsifying and thickening properties. It is commonly found in skin creams, lotions, and gels, where it improves the texture and stability of formulations. Moreover, HPMC is used in shampoos and hair conditioners to enhance viscosity and provide an appealing sensory experience for consumers. Its ability to form a protective film on the skin makes it an effective moisturizing agent as well, adding to its desirability as an ingredient.

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer derived from cellulose through a series of chemical modifications. It possesses unique properties that make it a vital component in various industries, including pharmaceuticals, cosmetics, construction, and food. Understanding the manufacturing process of HEC is essential for both manufacturers and end-users, as it highlights the intricacies involved in producing this versatile compound.

HPMC is derived from cellulose, a natural polymer obtained from plant cell walls. It is synthetically modified by introducing hydroxypropyl and methyl groups to the cellulose backbone. This modification increases its solubility in water, allowing it to form viscous solutions and gels. The degree of substitution (DS) of these groups determines the viscosity, solubility, and other physical attributes of HPMC, making it a tailor-made ingredient for specific requirements.

What is Hydroxyethyl Cellulose?

The properties of HPMC can be tailored by adjusting the degree of substitution and the molecular weight, allowing manufacturers to create specific grades for different applications. For instance, high-viscosity grades are commonly used as thickening agents, while lower viscosity grades are preferred for applications requiring easier flow and spreading.

The food industry also benefits from MHEC's unique properties. It is commonly used as a food thickener, stabilizer, and emulsifier. MHEC helps improve the texture and consistency of various food products, including sauces, dressings, and dairy items. Its ability to form gels and increase viscosity makes it a popular choice among food manufacturers aiming to enhance mouthfeel and product stability.

Der Markt für Hydroxyethylcellulose ist zudem stark von der Nachfrage seitens der Endverbraucher abhängig. In der Bauindustrie beispielsweise ist HEC wegen seiner Fähigkeit, die Konsistenz und Verarbeitbarkeit von Mörtel und Beton zu verbessern, sehr gefragt. In der Kosmetikindustrie wird HEC häufig als Verd thickungsmittel in Cremes und Lotionen eingesetzt, während es in der Pharmaindustrie zur Verbesserung der Fließfähigkeit und Stabilität von Formulierungen beiträgt. Eine steigende Nachfrage aus diesen Sektoren kann zu einem Anstieg der Preise führen.

Market Demand and Applications

Functions of HPMC in Pharmaceutical Formulations

Гидроксипропилметилцеллюлоза (HPMC) — это функциональный полимер, который широко используется в качестве добавки для клеев на основе цемента, в частности, для плиточных клеев. Его использование позволяет значительно улучшить свойства готового продукта, что делает HPMC незаменимым компонентом в строительной отрасли.

1. Mu Nzuzi

Conclusion

Another significant property of HPMC is its use as a controlled-release agent. Supplements formulated with HPMC can be designed to dissolve slowly in the digestive system, allowing for a gradual release of active ingredients. This controlled release can enhance the bioavailability of certain compounds, ensuring that nutrients are delivered efficiently to the body over an extended duration. Consequently, consumers may experience more sustained benefits from their supplements, which aligns with contemporary wellness trends that favor gradual and sustainable health improvements.

E tele fa'ato'aga i le lalolagi e fa'aaogaina le ciment ma le adhesive additive e taʻuina mai i le tele o le lelei i le fa'avae. O le fa'avae e fesoasoani i le su'esu'e i le fa'aogaina ma le fa'amaonia o meafaitino. O le faʻaaogaina o le 'adhesive additive' e le gata e tele ai vaega i le fa'avae o le ciment, ae e mafai fo'i ona fesoasoani i le si'itia o le lelei o le fa'avaa e aoga i le tupe.

Temperature is another crucial factor. The viscosity of HEC solutions typically decreases with an increase in temperature, a property that can be advantageous in applications that require easy processing at elevated temperatures. Conversely, cooling the solution will increase its viscosity, making it crucial to control the temperature for consistent performance.

Trotz seiner vielen Vorteile sind beim Einsatz von HPMC einige Überlegungen anzustellen. Es ist wichtig, die richtige Konzentration und Anwendungsmethode zu wählen, um die gewünschten Ergebnisse zu erzielen. Darüber hinaus kann die Qualität des HPMC je nach Hersteller variieren, was sich auf die Endprodukte auswirken kann. Daher ist es ratsam, stets auf hochwertige Quellen zu achten und gegebenenfalls Tests durchzuführen, um die Eignung für spezifische Anwendungen sicherzustellen.

1. Construction In the construction industry, dispersible polymer powders are commonly used as additives in cement-based materials. They enhance properties such as workability, adhesion, and water retention, contributing to the overall performance of concrete and mortars.

1. Enhanced Workability One of the primary advantages of adding HPMC to gypsum formulations is the improvement of workability. HPMC modifies the viscosity of the mixture, allowing for smoother and more efficient application. This is particularly important for plastering and leveling tasks, where easy maneuverability is key.

A hidroximetilcelulose propílica (HPMC) é um polímero derivado da celulose, amplamente utilizado em várias indústrias devido às suas propriedades únicas. Este composto é produzido a partir da modificação da celulose, um dos principais componentes das paredes celulares das plantas. A HPMC é solúvel em água e é conhecida por suas características de espessamento, adesão e formação de filme, o que a torna uma substância versátil em muitas aplicações.

Utilization in Food Products

In conclusion, the grades of HPMC significantly influence its viscosity and, consequently, its applications across various industries. Understanding these grades enables formulators to harness the desired properties of HPMC, customizing formulations to meet specific requirements. Whether in pharmaceuticals, food production, or construction, the proper selection of HPMC grades can enhance product performance, ensuring quality and satisfaction in end-user experiences. As industries continue to evolve, HPMC remains a critical component, highlighting the importance of continual research and development in this versatile field.

- Personal Care Products In cosmetic formulations, HPMC is valued for its ability to enhance texture and stability. It is commonly found in lotions, creams, and gels.

In addition to their practical benefits, cement bonding additives contribute to sustainable construction practices. By enhancing the durability of cement-based materials, these additives help decrease the frequency of repairs and rebuilds, leading to reduced material waste over time. Furthermore, some modern additives are formulated from recycled materials, aligning with the growing demand for environmentally friendly construction practices.

What is Redispersible Polymer Powder?

La poudre redispersible VAE est un polymère en poudre qui, lorsqu'il est mélangé avec de l'eau, forme une émulsion stable. Ce matériau est dérivé de copolymères d’acétate de vinyle et d’éthylène, qui lui confèrent d'excellentes propriétés adhésives et de flexibilité. Ce type de polymère est largement utilisé dans les mélanges de mortiers, les colles et d'autres applications de construction, où il joue un rôle crucial dans l’amélioration de la performance des matériaux.

Customer satisfaction is another cornerstone of HPMC Company's philosophy. The company prides itself on maintaining strong relationships with clients and providing exceptional customer service. By offering tailored solutions and technical support, HPMC Company ensures that its customers can effectively utilize HPMC in their applications, thereby enhancing their own product offerings.

4. Chợ Nguyên Liệu Thực Phẩm Với thị trường thực phẩm ngày càng đa dạng, HEC cũng được sử dụng trong ngành thực phẩm. Bạn có thể tìm thấy HEC tại các chợ nguyên liệu thực phẩm, nơi cung cấp các thành phần cho nhà hàng và ngành thực phẩm.

En outre, HPMC Solutions LLC met un accent particulier sur l'innovation. L'entreprise investit continuellement dans la recherche et le développement pour rester à la pointe des nouvelles technologies. Cela lui permet de proposer des solutions avant-gardistes qui répondent aux défis du marché moderne. L'intégration de l'intelligence artificielle, du big data et de l'internet des objets dans les services offerts est un exemple de l'engagement d'HPMC à fournir des solutions de haute technologie.

Redispersible powder is a significant material in various industries, primarily because of its unique properties that facilitate the creation of high-performance end products. This article will explore what redispersible powder is, its production process, and its applications across different sectors.

HPMC finds applications in various sectors, proving its versatility

The future of hydroxyethyl cellulose pricing will likely continue to be influenced by the factors mentioned above, along with emerging trends such as digital transformation in manufacturing and shifts towards green chemistry practices. As consumers increasingly favor sustainable products, companies that can adapt to these changes while managing costs effectively may find themselves in a favorable position in the HEC market.

HPMC powder is a white, odorless, and tasteless powder that is soluble in water. It forms a viscous gel when mixed with water, making it an effective thickening agent. One of the remarkable properties of HPMC is its ability to form a film, which can protect the active ingredients in formulations, making it ideal for controlled-release drug delivery systems. The degree of substitution, which refers to the number of hydroxypropyl and methyl groups attached to the cellulose backbone, can be modified to tailor the properties of HPMC for specific applications.

Hydroxypropyl Methyl Cellulose in Supplements An Overview