2x2 ceiling tiles cheap

-

Have you ever noticed that suspended ceilings are everywhere, from your local barbershop to storefronts, and even in restaurants and office spaces? It’s because they perform! They help make those spaces more enjoyable thanks to better acoustics, moisture resistance, light reflectance, and even cleanability.

...

Links

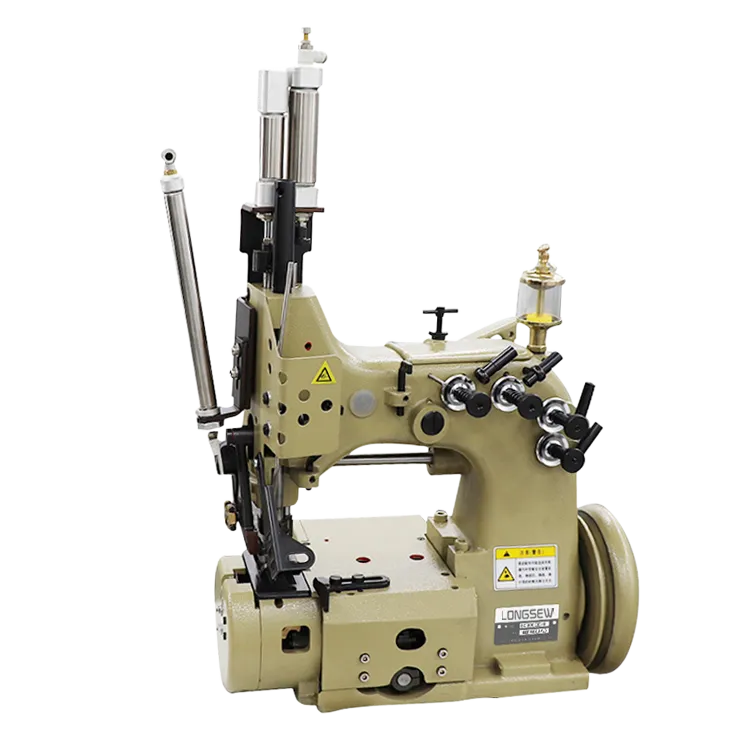

Precision is critical in quilting, and multi needle machines excel in this area. The synchronized movement of multiple needles ensures that every stitch is consistently placed, resulting in professional-quality finished quilts. The machines are often equipped with advanced features such as automatic tension adjustments and stitch regulation, which help maintain consistency and accuracy throughout the quilting process. This level of precision is particularly beneficial for detailed work, such as free-motion quilting or appliqué.

As a beginner, you may encounter a few common problems

At its core, a zig zag embroidery machine is designed to create zigzag stitches—an essential technique in both sewing and embroidery. Unlike straight stitches, zigzag stitches offer flexibility, stretch, and durability, making them ideal for embellishing a variety of fabrics. The machine’s ability to switch between zigzag and straight stitches allows for seamless transitions between different styles of embroidery, enabling users to create intricate designs with ease.

The Timeless Craft of Manual Leather Sewing Machines

In terms of market growth, the bag making machine industry has witnessed considerable expansion due to globalization and e-commerce. As online shopping continues to rise, the need for efficient packaging solutions has become more critical. Retailers require a reliable source of bags that can be produced quickly and in large quantities to meet shipping demands. Bag making machines play a vital role in this supply chain, ensuring that businesses can operate smoothly and meet consumer expectations.

Applications of Lock Stitch Machines

7. Embroidery Foot If you're interested in machine embroidery, an embroidery foot is essential. It provides a clear view of your sewing area, allowing for intricate designs to be stitched without obstruction.

4. User-friendly Interface With advancements in technology, modern sewing machines often feature intuitive control panels, making them easier to operate and adjust for different fabrics and bag specifications.

The Cost of Zigzag Sewing Machines An Overview

Conclusion

Additionally, the machine’s design minimizes the likelihood of common sewing issues, such as thread breaking or tension irregularities. Many users report that the Cub Leather Sewing Machine provides consistent performance, allowing them to complete projects efficiently and to a high standard.

User-Friendly Features

An industrial serger machine, also known as an overlock sewing machine, is a type of sewing machine that uses multiple threads (usually two to five) to stitch and finish seams. Unlike traditional sewing machines that only create a single line of stitching, sergers can sew, cut, and finish edges all in one step. This capability not only saves time but also enhances the overall durability and stretch of the garment, making it ideal for stretchy fabrics like knits and jerseys.

An industrial overlock sewing machine is designed to join two or more pieces of fabric together while simultaneously trimming the excess fabric at the edges. It uses multiple threads and specialized stitches to create a secure, professional-looking finish. The term overlock comes from the machine's ability to wrap the thread around the edge of the fabric, preventing fraying and creating a clean look. This makes them particularly useful for knit and stretch fabrics, which are common in modern apparel.

In conclusion, when considering the purchase of a portable bag closer machine, it's essential to evaluate your specific needs and the nature of your operations. While price is a significant factor, it should also be weighed against quality, durability, available features, and potential long-term savings. Investing in a reliable portable bag closer machine can enhance operational efficiency and ultimately lead to greater profitability in your business endeavors. Whether you are a small business or a large-scale manufacturer, careful consideration of these factors can lead to a well-informed purchase decision.

Buyers should also consider the potential for used or refurbished cylinder bed sewing machines. The second-hand market can offer significant savings, with prices often reduced by 30-50% compared to new models. However, it is crucial to examine the condition of the machine, verify its maintenance history, and potentially factor in the cost of repairs or refurbishment.

commercial sewing machine needles. From heavy-duty needles for sewing leather and upholstery to fine needles for delicate fabrics like silk and chiffon, there is a needle for every sewing need. Choosing the right needle for the job is crucial for achieving professional and high-quality results in any sewing project.