rondo ceiling access panels

In summary, understanding T-bar ceiling grid dimensions is imperative for anyone involved in construction or renovation projects. From ensuring aesthetic appeal to maintaining functionality, the right dimensions play a crucial role in the overall success of the ceiling system. By considering standard sizes, the importance of proper dimensions, and potential customization options, you will be better prepared to make informed decisions that enhance both the visual and practical aspects of your space. Whether you are a contractor, architect, or property manager, grasping the nuances of T-bar ceiling grids will ultimately lead to more successful and satisfying project outcomes.

Aesthetic Versatility

- Access panel frame kit These can be purchased at hardware stores and come in various sizes.

Psychological Factors

Despite the benefits of using gypsum in PVC production, challenges remain. The processing of gypsum can be energy-intensive, and there are concerns regarding the consistent quality and supply of gypsum as a raw material. Additionally, the thermal properties of gypsum need to be thoroughly understood to optimize its performance in various PVC applications.

Links

-

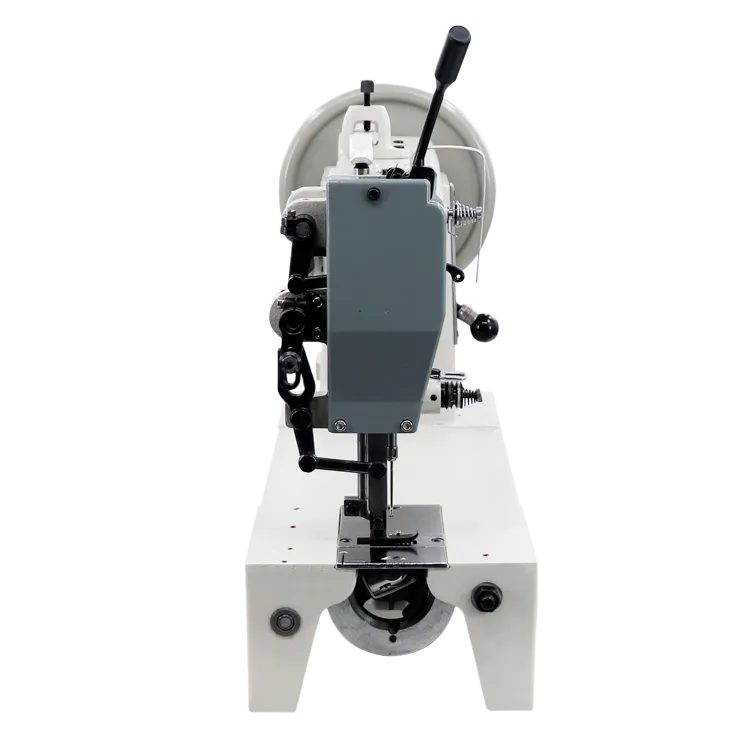

The high-speed single needle lockstitch sewing machine operates using a simple yet effective mechanism. It utilizes a single needle that passes through the fabric layers, forming a lockstitch by interlocking the upper thread with the lower thread supplied from the bobbin. This design not only ensures durability and strength in the seams but also allows for a wide range of stitches, from basic straight stitches to more complex patterns.

-

Conclusion

-

In conclusion, the price of cylinder bed sewing machines can vary widely based on a variety of factors, including brand reputation, features, construction quality, intended application, and whether the machine is new or used. For businesses focused on efficiency and quality, investing in a cylinder bed sewing machine can prove beneficial, provided that careful consideration is given to these price-influencing factors. Ultimately, a well-chosen machine can enhance productivity and elevate the standard of finished products, making it a valuable addition to any industrial sewing operation.

-

Cylindrical bed sewing machines are especially beneficial in the sportswear and knitwear sectors, where tubular garments are predominant. For example, when sewing t-shirts or sweatshirts, the cylindrical bed allows operators to sew along circular features without having to reposition the entire garment multiple times. This capability saves considerable time, increases productivity, and reduces the potential for fabric distortion, which can occur when moving bulky items through a straight stitching path.

-

×

It can operate continuously for extended periods, sealing hundreds of bags per hour, which would be near impossible to achieve manually It can operate continuously for extended periods, sealing hundreds of bags per hour, which would be near impossible to achieve manually

It can operate continuously for extended periods, sealing hundreds of bags per hour, which would be near impossible to achieve manually It can operate continuously for extended periods, sealing hundreds of bags per hour, which would be near impossible to achieve manually