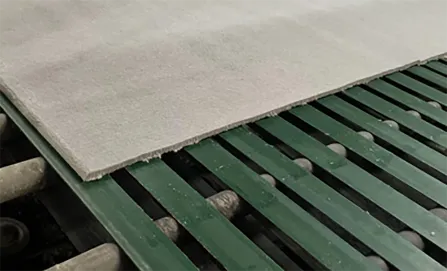

gridless ceiling tiles

-

In addition to their practical benefits, metal wall and ceiling access panels offer aesthetic advantages. Available in various finishes and designs, they can seamlessly blend with different interior styles. Whether the application is in a hospital, office building, or residential home, metal access panels can be customized to match the surrounding décor. This attention to visual appeal ensures that they do not detract from the overall design of the space, maintaining a polished and professional look.

...

-

...

1. Durability and Longevity

1. Choose the Right Location

5. Versatility in Design The 600x600 hatch can be designed to blend seamlessly with various ceiling finishes. Many manufacturers offer multiple surface options, including textured finishes that match the surrounding ceiling material, providing a polished appearance while still being functional.

Gyproc PVC false ceilings are known for their durability. Unlike traditional ceiling materials like plaster or wood, PVC is resistant to moisture, rot, and insects. This makes Gyproc PVC particularly suitable for areas with high humidity, such as bathrooms and kitchens, where conventional ceilings may deteriorate over time. Maintenance is also straightforward; they can simply be wiped clean with a damp cloth to remove dust and stains, ensuring they retain their aesthetic appeal with minimal effort.

gyproc pvc false ceiling

In summary, ceiling trap doors are essential components in modern construction, providing necessary access for maintenance and inspection while ensuring safety and functionality. As their importance continues to grow in various sectors, finding a reliable supplier becomes paramount. By considering factors such as product range, quality, customization, customer service, and reputation, clients can successfully identify suppliers that meet their needs. Whether for a new construction project or an upgrade to an existing building, the right ceiling trap door supplier can make all the difference in achieving a safe and efficient environment. With a range of options available, businesses and homeowners alike can benefit from the practical advantages that ceiling trap doors provide.

Easy Installation and Maintenance

The installation of a suspended ceiling access hatch is a straightforward process but should be performed by professionals to ensure proper fit and function. The first step involves determining the appropriate location for the hatch based on the systems that need to be accessed. Once selected, the area is measured and marked.