oem mineral fiber ceiling tiles

Durability

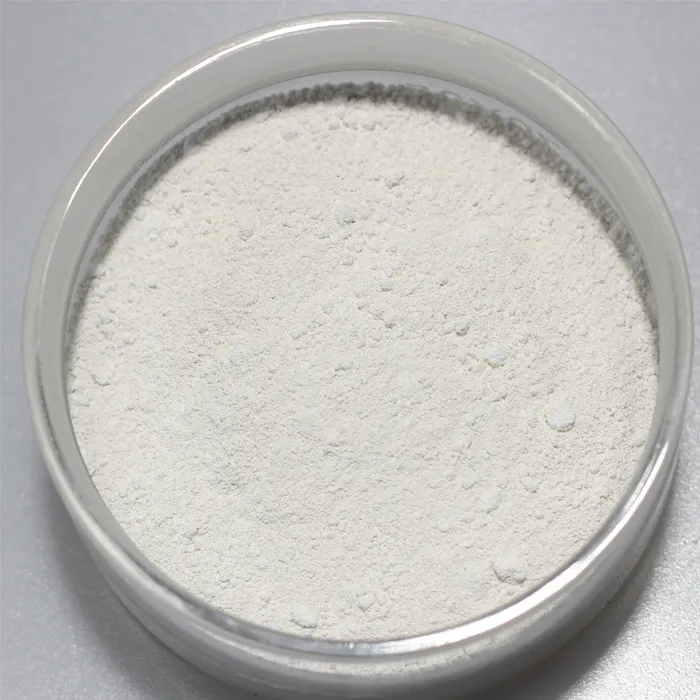

What Are Mineral Fiber Ceiling Tiles Made Of?

The Versatile Application of Ceiling T Bar Clips

5. Lightweight and Easy to Install Installation of ceiling tiles can be a daunting task, but vinyl coated gypsum tiles are lightweight, which simplifies the process. They can be installed with minimal tools and expertise, allowing for quicker project completion times. This convenience is particularly beneficial for large-scale commercial projects where time is of the essence.

One of the primary benefits of plastic drop ceiling grids is their lightweight nature. Compared to metal grids, which can be cumbersome and difficult to handle during installation, plastic grids are much easier to manipulate. This feature not only speeds up the installation process but also reduces labor costs and the potential risk of injury during handling. Consequently, builders and contractors are increasingly turning to plastic grids for their projects.