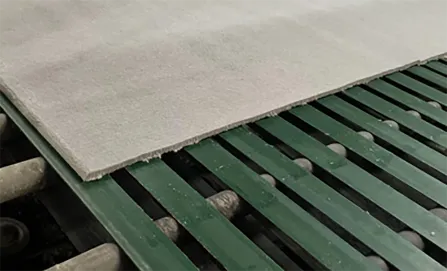

mineral fiber panels

Links

-

- One of the key advantages of R1930 is its high refractive index, which allows it to scatter light more effectively, resulting in superior opacity and whiteness. This makes it an ideal choice for ink formulations that require high levels of coverage and brightness. Additionally, R1930's excellent heat stability ensures that it can withstand the high temperatures encountered during the printing process without losing its color or physical properties.

- One way to find reliable suppliers for barium sulfate is to use online platforms that connect buyers and sellers. These platforms allow you to request quotations from multiple suppliers and compare their prices and quality. You can also read reviews and ratings from other customers to ensure that you are choosing a reputable supplier.

- Another notable supplier is Company B, who specializes in customized solutions

2. Particle Size The application often dictates the required particle size. Suppliers typically offer various grades of barium sulphate, categorized by their particle size distribution. For example, finer particle sizes are often favored in cosmetic applications, while coarser grades may be used in construction materials.

What's everyone talking about? Sign up for our trending newsletter to get the latest news of the day

Further outstanding properties of Lithopone are its high lightness, neutral white colour and its diffuse reflectance in the near UV range.

There's also evidence that inhaling titanium dioxide particles can be dangerous. That's mainly a concern for industrial workers. In places where it's produced, or where it's used to make other products, workers can breathe it in as a dust. The Occupational Health and Safety Administration has exposure standards manufacturers must meet.

Although the evidence for general toxic effects was not conclusive, on the basis of the new data and strengthened methods we could not rule out a concern for genotoxicity and consequently we could not establish a safe level for daily intake of the food additive, commented Matthew Wright, member of the EFSA's Food Additives and Flavourings Panel in a press statement.

Numerous studies have linked titanium dioxide to genotoxicity and cytotoxicity. Genotoxicity refers to a chemical’s potential to cause DNA damage, which can, in turn, lead to cancer. Cytotoxicity is a general term that refers to a characteristic of being harmful to cells.

The Scientific Facts

Lithopone B301

What other candies and food contain titanium dioxide?

≥28.0

These companies have established reputations for producing high-quality titanium dioxide powder that meets stringent quality standards These companies have established reputations for producing high-quality titanium dioxide powder that meets stringent quality standards

These companies have established reputations for producing high-quality titanium dioxide powder that meets stringent quality standards These companies have established reputations for producing high-quality titanium dioxide powder that meets stringent quality standards cas: 13463-67-7 titanium dioxide powder suppliers.

cas: 13463-67-7 titanium dioxide powder suppliers. Titanium dioxide R-5566, a rutile titanium dioxide pigment treated with zirconium and aluminum inorganic surface and organic surface, has the characteristics of high whiteness, high gloss, high achromatic power, high weather resistance, and good dispersibility.

Neutral White, 26 per cent zinc sulphide, 66 per cent barium sulphate, 5 per cent infusorial earth, 3 per cent whiting.

Following a request for assessment in 2020 by the EU, the European Food Safety Authority (EFSA) assessed E171, particularly for its genotoxicity. In 2022, the agency deemed the food additive no longer safe for use.

This has led to the development of specialized grades tailored to specific industrial requirements This has led to the development of specialized grades tailored to specific industrial requirements

This has led to the development of specialized grades tailored to specific industrial requirements This has led to the development of specialized grades tailored to specific industrial requirements r 298 titanium dioxide factories.

r 298 titanium dioxide factories.

5. Regulatory compliance The MSDS should also include information on regulatory requirements for the safe handling and use of lithopone, including any permits or certifications that may be necessary.

lithopone b301 28% manufacturers. It is important to choose a manufacturer that has the necessary infrastructure and capabilities to meet the specific requirements of the business.