oem ceiling tile

-

...

...

Links

On average, the price for a basic jute bag sewing machine falls between $400 and $1,000. These machines are typically suitable for small-scale production and can handle standard sewing tasks required for making jute bags. For businesses looking to increase productivity and output, investing in semi-automatic or fully automatic machines may be necessary, with prices ranging from $1,500 to $5,000.

When it comes to pricing, auto sewing machines can range from as low as $200 to over $5,000. Several factors affect the price points of these machines

Cylindrical bed sewing machines are especially beneficial in the sportswear and knitwear sectors, where tubular garments are predominant. For example, when sewing t-shirts or sweatshirts, the cylindrical bed allows operators to sew along circular features without having to reposition the entire garment multiple times. This capability saves considerable time, increases productivity, and reduces the potential for fabric distortion, which can occur when moving bulky items through a straight stitching path.

This not only saves time but also reduces errors that could otherwise mar the final product This not only saves time but also reduces errors that could otherwise mar the final product

This not only saves time but also reduces errors that could otherwise mar the final product This not only saves time but also reduces errors that could otherwise mar the final product automatic leather sewing machine.

automatic leather sewing machine. Maintenance and Care

In conclusion, the floating foot sewing machine has redefined the sewing landscape by providing enhanced precision, flexibility, and user-friendly features. Whether you are a budding enthusiast or a seasoned professional, integrating this innovative sewing tool into your crafting toolkit can significantly elevate your sewing experience. As technology continues to evolve, it’s exciting to foresee what other advancements will shape the future of sewing, but for now, the floating foot machine stands out as a definitive asset in the world of textiles. Embracing this technology not only streamlines the sewing process but also opens up endless possibilities for creativity and craftsmanship in every stitch.

Conclusion

One of the primary functions of an overlocker is to finish raw edges of fabric. This is particularly useful for knit fabrics, which tend to stretch and curl. Overlocking edges with a serger provides a professional finish that is both durable and visually appealing. The machine utilizes multiple threads to create a strong seam, making it ideal for garments that require flexibility, such as t-shirts, leggings, and activewear.

7. Automatic Features

Key Features of Industrial Serger Machines

In the world of leatherworking, precision and efficiency are paramount. Among the many tools available to leather artisans, the cylinder arm sewing machine stands out as a transformative innovation, revolutionizing the way leather products are crafted. This article delves into the features, benefits, and applications of cylinder arm sewing machines in leatherworking, highlighting their significance in modern manufacturing.

The Double Needle Price A Comprehensive Insight

One of the key advantages of the single needle stitch is its versatility. It is commonly employed in various applications, from delicate hems on silk dresses to intricate embellishments on leather goods. Designers often opt for this stitch when they aim to achieve a clean and minimalist aesthetic. Moreover, the single needle stitch is ideal for working with lightweight and sheer fabrics, where bulkiness might ruin the overall look.

Investing in bulk bag sewing machines is also a decision centered around durability. These machines are built to withstand the rigors of industrial environments, which often include dust, debris, and high operational stress. Regular maintenance and adherence to manufacturer guidelines can prolong the lifespan of these machines, ensuring that the initial investment proves valuable over time.

Heavy-duty and industrial sewing machines serve distinct needs, with the former bridging the gap between household and professional machines. While industrial units excel in continuous, specialized tasks, heavy-duty machines can effectively sew light fabrics when tailored with appropriate settings, such as stitch length, tension control, and needle choices. However, challenges like machine speed, feed dogs, and thread choice need careful management. Regular maintenance and choosing versatile machines, backed by expert advice and reviews, can ensure optimum results across various fabrics, from robust denim to delicate silks.

In addition to their speed and efficiency, woven sack sewing machines are also known for their durability and reliability. These machines are built to withstand heavy use and are designed to operate consistently and reliably, even in challenging industrial environments.

Finally, investing in a heavy duty sewing machine can be economically advantageous for businesses and serious hobbyists alike. The durability of these machines often translates into a longer lifespan, reducing the need for frequent repairs or replacements.

1. Finishing Edges

For those who enjoy working with knit fabrics, a serger machine is particularly advantageous. Traditional sewing machines can struggle with stretch fabrics, leading to puckering or popping seams. The overlock stitch produced by a serger machine is designed to allow for some stretch. This makes it perfect for sewing activewear, fitted garments, and any project where flexibility is key. The differential feed feature present in many sergers helps to manage fabric movement, eliminating issues like stretching or bunching.

One of the primary advantages of using a walking foot sewing machine is its ability to handle difficult materials. Quilters, for instance, often require a machine that can manage several layers of batting and fabric without distorting the design. The 2% needle walking foot sewing machine excels in such tasks, ensuring smooth transitions between layers and perfectly aligned stitches. This functionality facilitates the creation of intricate quilts and detailed designs, which can be a challenge with standard presser feet.

Features to Consider

4. Adjusting the Tension and Stitch Settings

1. Choosing the Right Machine and Needles

Understanding the factors influencing auto sewing machine prices is crucial for potential buyers. From selecting the right features to considering the brand and technological advancements, consumers should evaluate their needs and budget carefully. By taking the time to research and compare prices across various platforms, buyers can find the ideal sewing machine that balances quality, functionality, and cost. Whether you’re a seasoned professional or just starting out, the right sewing machine can make all the difference in bringing your creative visions to life.

The machine's operation is facilitated by a specific type of feed mechanism, usually a walking foot or a needle feed system, that ensures the even feeding of fabric layers, particularly useful when working with thick or slippery materials. The combination of the double needle and advanced feed mechanisms allows for precise control over the fabric, enabling users to achieve consistent stitch quality throughout the sewing process.

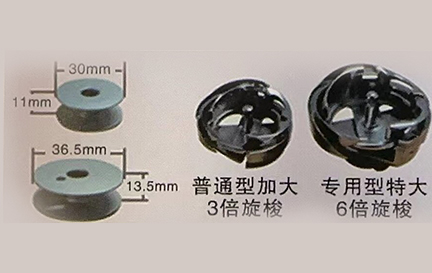

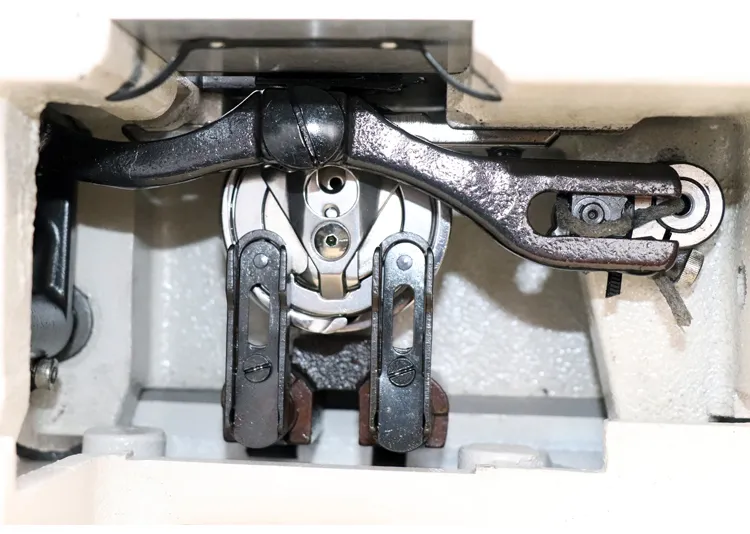

The design of the bobbin shuttle hook has evolved significantly over the years. Early sewing machines used a simple curved hook, which, while functional, lacked the efficiency and speed of modern designs. The introduction of the rotary hook mechanism revolutionized the sewing industry. This design allowed for faster sewing speeds, better stitch quality, and reduced the noise associated with older machines. The intricacies of modern bobbin shuttle hooks are a testament to years of innovation and engineering, culminating in a component that is both robust and efficient.

In conclusion, the sewing machine chain has played a pivotal role in the evolution of textile production, impacting everything from industrial manufacturing to home crafting. While it has increased efficiency and facilitated the rise of fast fashion, it has also prompted discussions about sustainability and ethical practices in the garment industry. As we continue to embrace innovation in sewing technology, it is essential to remain mindful of the implications of our choices on the environment and society. The sewing machine chain stands as a testament to human ingenuity and adaptability, shaping our world as we sew the fabric of our lives.

3. Ease of Use Consider the learning curve associated with a particular model. Some machines may have more complex threading systems or require specific needle types. Opt for a user-friendly machine if training staff is a concern.

In the realm of industrial manufacturing, efficiency and productivity are paramount. One of the key players in this aspect is the bulk bag sewing machine, an essential tool for industries that rely on packaging bulk materials. As industries evolve and the demand for more efficient packaging solutions increases, these machines have become increasingly sophisticated, ensuring that they meet the diverse needs of various sectors.

Sewing is a timeless craft that has evolved immensely over the years, and with technological advancements, sewing machines have become more sophisticated and user-friendly. One such innovation that stands out is the sewing machine with a built-in walking foot. This feature has transformed the way both amateur and professional seamstresses tackle their projects, making sewing more efficient and enjoyable.

In the world of sewing and fashion design, the tools we choose can make a significant difference in how we execute our creative vision. One pivotal tool that has gained immense popularity among both amateur and professional sewists is the Dressmaker Zig Zag Sewing Machine. With its unique capabilities, this machine not only enhances creativity but also offers practicality and versatility in various sewing projects.

4. Cutting Blade For machines that seal bags at the same time they are cutting, the cutting blade plays a critical role. It ensures that each bag is of uniform size and cuts through the material cleanly. A sharp and well-maintained blade contributes to the overall efficiency and prevents material wastage.

Second, use appropriate needles and thread for your fabric type. Heavy-duty needles are ideal for thick fabrics, while finer needles work better on lighter materials. Finally, take your time and sew at a steady pace. Rushing can lead to mistakes, especially when working with bulky fabrics.

As the eco-conscious movement grows globally, more manufacturers are also turning to sustainable practices. Jumbo bag sewing machinery is adapting to this trend, with many companies now using recyclable materials in the production of bags. Some sewing machines are designed to work with these biodegradable or recyclable materials, promoting a greener approach to manufacturing.

Additionally, there are different types of lock stitch needles designed for varied applications. For instance, needles with a rounded tip are ideal for sewing knit fabrics, as they slide between the fibers rather than piercing them, reducing the risk of snagging. Conversely, a sharp needle is perfect for woven fabrics, as it can easily penetrate the tight weave, creating clean and precise stitches. Specialty needles, such as twin needles for parallel stitching or quilting needles for multi-layered quilts, also contribute to the versatility of sewing projects.