Links

-

Temperature is another critical factor that impacts the solubility of HPMC in cold water. While HPMC can dissolve in cold water, the solubility can be further enhanced by allowing the solution to reach a slightly elevated temperature without boiling. This process helps in reducing the viscosity initially and facilitates the mixing of HPMC into the water. However, when formulating, it is essential to consider that prolonged exposure to high temperatures can lead to the degradation of the polymer, adversely affecting its properties.

-

5. Industry Trade Shows

Recent Trends in Hydroxyethyl Cellulose Pricing

In the food industry, HEC is utilized as a food additive, enhancing the texture and stability of various products. Its gelling properties allow it to act as a stabilizer in sauces, dressings, and dairy products, contributing to a desirable mouthfeel and consistency. Importantly, HEC is classified as Generally Recognized As Safe (GRAS) by the U.S. Food and Drug Administration (FDA), allowing its use in food products without health concerns.

hydroxyethyl cellulose sds

Mechanism of Action

Moreover, the geographical location of suppliers can significantly influence logistics and supply chain efficiency. Suppliers who can provide timely delivery and localized support enhance their attractiveness to contractors and manufacturers. As projects often involve strict timelines, having a reliable supplier that can ensure the availability of RDPs is crucial in maintaining project flow and avoiding delays.

Repair and restoration materials: such as concrete repair and restoration mortar, plastering mortar, floor mortar, etc. Redispersible powder can enhance the adhesion and durability of these materials, making repair and restoration effects more significant and long-lasting.

In the pharmaceutical sector, hydroxyethyl cellulose is utilized as a binder and a controlled-release agent in tablet formulations. Its non-toxic and biodegradable nature makes it safe for use in medicines, while its ability to modify the release of active ingredients ensures prolonged therapeutic effects. HEC is also used in ophthalmic preparations, where it helps to maintain moisture levels in the eyes and improve the comfort of contact lens wearers. Due to its various functionalities, HEC plays a critical role in enhancing the efficacy of pharmaceutical products.

Conclusion

HPMC is derived from cellulose, a natural polymer, through a chemical process that involves the substitution of hydroxyl groups. This modification enhances its solubility in cold water, a characteristic that distinguishes HPMC from other cellulose ethers. The number “200000” in HPMC 200000 refers to its viscosity, specifically about 2,000,000 mPas when measured in a 2% aqueous solution at 20 degrees Celsius. This high viscosity indicates its ability to provide substantial thickness to formulations, making it ideal for a variety of applications.

4. Faster Setting Times Some bonding agents can accelerate the setting time of mortar. This is advantageous in projects that require quick completion or in colder weather conditions where traditional mortar takes longer to set.

Conclusion

Purchasing HPMC requires careful consideration of various factors, including quality, viscosity grades, application-specific properties, cost, supplier reputation, and sustainability. By thoroughly researching and evaluating your options, you can ensure that you select the right HPMC for your needs. Whether you are in the pharmaceutical, food, or construction industry, understanding these facets will lead to more effective and successful applications of this versatile polymer.

The incorporation of RDP in construction materials offers multiple advantages

2. Flexibility and Elasticity REP imparts flexibility and elasticity to dry mix formulations, allowing them to withstand thermal expansion and contraction without cracking. This is especially important in areas with significant temperature fluctuations, ensuring the longevity of the materials.

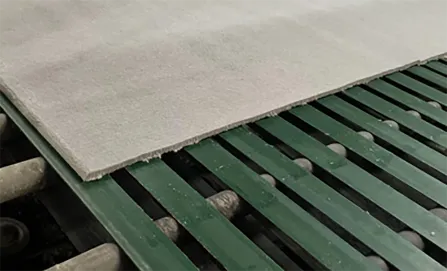

redispersible emulsion powder

Environmental and Safety Considerations

1. Improved Workability When added to gypsum formulations, HPMC significantly improves the workability of the mix. This makes it easier for applicators to spread, shape, and finish the gypsum without compromising its structural integrity. The enhanced workability is essential for achieving a smooth surface and ensuring that the gypsum adheres well to various substrates.

HEC is produced by the etherification of cellulose, where ethylene oxide reacts with cellulose in an alkaline medium. This process results in a stable, white powder that is easy to handle and dissolve in water. The degree of substitution of hydroxyl groups with hydroxyethyl groups on the cellulose chain determines the viscosity and solubility properties of HEC, allowing for customization according to specific needs.

Several factors can influence the solubility of HEC in water

. These includeIn the food industry, HPMC has become an essential ingredient in various products, from baked goods to sauces. It acts as an emulsifier and stabilizer, improving texture and moisture retention. Health-conscious consumers are increasingly turning to products that contain fewer additives and chemicals, which influences food manufacturers to utilize HPMC as a plant-based alternative to synthetic additives. Moreover, its vegan-friendly nature has made it a popular choice in the production of gluten-free and plant-based foods, catering to evolving dietary preferences.

hpmc 200000

The combination of HPMC and CMC can create a synergistic effect, enhancing their individual properties for better performance in practical applications. In the pharmaceutical industry, HPMC is often employed in the formulation of tablets and capsules, serving not only as a binder but also as a stabilizing agent. When combined with CMC, the gel-forming properties of the combination can lead to improved drug delivery systems, allowing for sustained drug release and better bioavailability.

hpmc cmc

Dispersible polymer powders are a remarkable innovation in material science, offering a myriad of benefits across different industries. Their unique characteristics, such as excellent water solubility, rheological enhancement, and tailored functionalities, position them as essential additives in formulations for construction, coatings, adhesives, and textiles. As technology advances and environmental considerations become increasingly important, the demand for effective and efficient materials like dispersible polymer powders will continue to grow, paving the way for future innovations and applications. In an ever-evolving marketplace, these powders stand out as crucial components for enhancing product performance and sustainability.

In the realm of cosmetics and personal care, HPMC is utilized for its thickening and film-forming properties. It is an essential component in products such as shampoos, conditioners, lotions, and creams, helping to create a desirable texture while providing stability to emulsions. HPMC allows for improved application and spreadability, enhancing the overall user experience. Furthermore, its water-retaining properties make it beneficial in moisturizing products, keeping skin hydrated and enhancing the efficacy of active ingredients.

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose ether widely used in various construction materials, particularly gypsum-based products. Its unique properties make it an essential additive that enhances the performance of gypsum in construction applications. This article explores the various benefits, applications, and considerations of using HPMC in gypsum formulations.

1. Pharmaceuticals In drug delivery systems, the use of HPMC at its gelation temperature allows for the creation of matrices that can control the release of drugs over extended periods. This is particularly useful for medications that require gradual release to maintain therapeutic levels in the bloodstream.

Another key property of HPMC is its viscosity, which can be tailored by varying the degree of substitution and the molecular weight during synthesis. This variability allows for the customization of HPMC for specific applications, meeting the needs of different industries. Additionally, HPMC is compatible with a wide range of other agents, such as surfactants, polymers, and salts, further enhancing its utility in formulation.

In agriculture, hydroxyethyl cellulose serves as a useful tool in the formulation of agricultural products. It can be used as a soil conditioner, improving soil structure and water retention. Furthermore, HEC is often included in pesticide formulations to enhance the adherence of active ingredients to plant surfaces, ensuring better efficacy of the chemicals applied. Its biodegradable nature aligns with the increasing demand for environmentally friendly agricultural practices.

5. Agriculture

Understanding HPMC Solubility Importance and Applications

Environmental considerations have further highlighted the advantages of using hydroxyethylcellulose. Being derived from renewable resources, HEC aligns with the growing demand for sustainable and eco-friendly ingredients across various sectors. Its biodegradable nature also contributes to reducing environmental impact, a critical factor as industries strive to adopt green practices.

As global industries continue to shift towards sustainable practices, the compatibility of redispersible powder polymers with eco-friendly formulations has become increasingly important. Many RDCs can be formulated to be low-VOC (volatile organic compound), thus minimizing environmental impact. Their ability to be used in conjunction with sustainable materials further supports the drive for greener products without compromising on performance.

4. Temperature The viscosity of HEC is affected by temperature. Generally, an increase in temperature results in a decrease in viscosity, which affects its application in temperature-sensitive environments. Formulators must consider this factor to ensure consistent product performance.

hydroxyethyl cellulose viscosity

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer derived from cellulose, which is widely used in various industries, including construction, pharmaceuticals, cosmetics, food, and oil drilling. Its unique properties, such as thickening, emulsifying, and stabilizing, make it an invaluable ingredient in many applications. Understanding the price per kilogram of hydroxyethyl cellulose is essential for businesses and individuals who rely on this versatile material.

Conclusion

HPMC has also carved out a significant role in the construction industry, particularly in the formulation of cement-based products. As a water-retaining agent, HPMC helps improve the workability of mortars and plasters, allowing for longer working times and enhanced adhesion. This polymer plays a crucial role in preventing cracking and shrinking in dried cement mixtures. When added to tile adhesives, HPMC enhances their performance by providing better adhesion and flexibility, which is essential in various construction applications.

hpmc chemical

In the modern construction and building materials industry, redispersible polymer powders (RDP) have gained significant attention due to their versatile applications and numerous benefits. These fine powders are made from various types of polymers, most commonly vinyl acetate-ethylene (VAE) copolymers, which, when mixed with water, can revert to a liquid state. This unique property makes them incredibly useful in a variety of applications, from adhesives and sealants to dry-mix mortars and coatings. Consequently, the role of redispersible polymer powder manufacturers has become increasingly crucial.

Hydroxypropyl Methyl Cellulose (HPMC) is a versatile cellulose ether that has garnered significant attention across various industries, including pharmaceuticals, food, construction, and personal care. As a supplier of this essential compound, HPMC manufacturers play a vital role in facilitating the production of products that millions of people rely on daily.

Innovative Tools and Technology

2. Pharmaceuticals HEC is employed as a binder, film former, and stabilizer in various pharmaceutical formulations, including tablets and topical ointments. Its non-toxic nature and compatibility with different drug components make it a preferred choice for formulators.

The Importance of Hydroxy Methyl Cellulose in Modern Applications

What is HPMC?

Redispersible polymer powder (RPP) plays a crucial role in various industries, especially in construction, coatings, and adhesives. It is a powdered form of polymer that can be easily redispersed in water, resulting in a stable dispersion. This property makes RPP an invaluable additive, improving the performance and quality of various products.

HPMC is favored in many applications due to its non-toxic nature, high viscosity, and ability to form films. The solubility of HPMC in ethanol can vary based on several factors, including its molecular weight and the degree of substitution, which refers to the amount of hydroxypropyl and methoxy groups present in its structure. Generally, HPMC is soluble in polar solvents, but its solubility in ethanol is more nuanced as ethanol is a semi-polar solvent.

In conclusion, hydroxyethyl cellulose is a multifunctional polymer that serves a wide variety of roles across several industries. From enhancing the texture and stability of personal care products to playing a crucial role in pharmaceuticals, food, and construction, HEC is integral to numerous applications. Its versatility, combined with its natural origins, positions hydroxyethyl cellulose as a valuable ingredient in the ongoing pursuit of quality in consumer products and industrial applications alike.

Water Retention and Workability

Factors to Consider When Buying HPMC

In the food industry, HPMC serves as a food additive known for its emulsifying, stabilizing, and thickening abilities. It is commonly used in a variety of products, including sauces, dressings, and baked goods. By enhancing texture and improving moisture retention, HPMC helps to create enjoyable sensory experiences while extending the shelf life of food products. Additionally, HPMC is often utilized in gluten-free and low-calorie foods, as it aids in mimicking the properties of gluten while limiting calorie content.

hpmc solution