cross tees suspended ceiling

-

...

...

...

...

...

...

Links

The Importance of Bracing in Structures

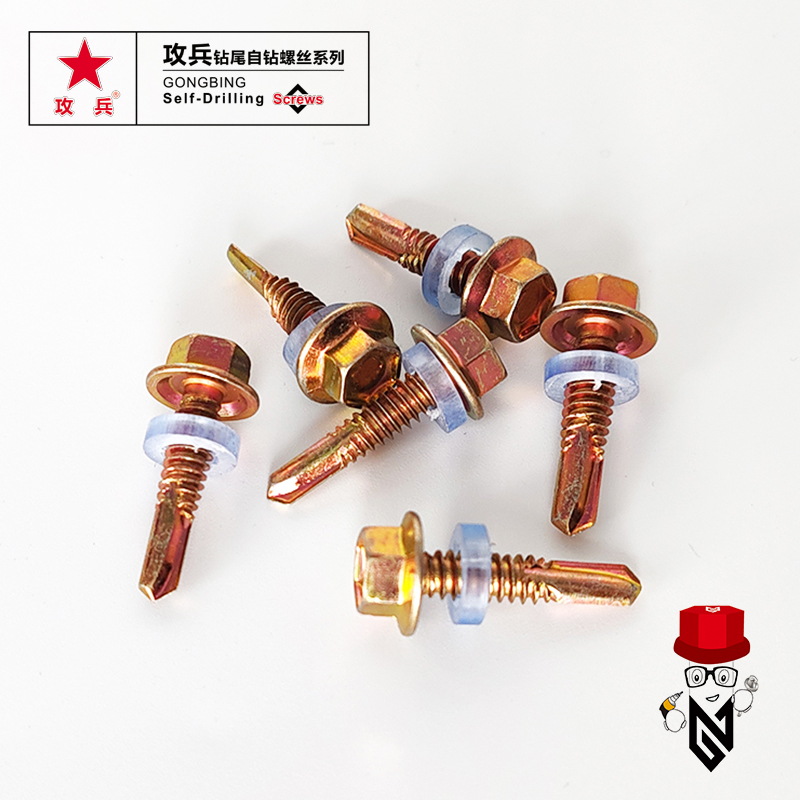

In conclusion, hex head self-tapping bolts represent a practical and efficient fastening solution across various industries. Their unique design, combined with flexibility and ease of installation, makes them indispensable in both professional and DIY applications. Understanding their features and applications can pave the way for better project outcomes and stronger connections in construction and manufacturing tasks.

This property makes them ideal for outdoor use or in industries like marine, chemical processing, and food service where exposure to moisture and chemicals is common This property makes them ideal for outdoor use or in industries like marine, chemical processing, and food service where exposure to moisture and chemicals is common

This property makes them ideal for outdoor use or in industries like marine, chemical processing, and food service where exposure to moisture and chemicals is common This property makes them ideal for outdoor use or in industries like marine, chemical processing, and food service where exposure to moisture and chemicals is common ss 304 self drilling screw.

ss 304 self drilling screw. Tek screws serve as an essential component in modern cladding systems, providing strength, efficiency, and resistance to environmental factors. By understanding their characteristics, applications, and best practices, construction professionals can ensure a robust and reliable cladding installation, contributing to the longevity and performance of buildings. As construction technologies continue to evolve, Tek screws will likely remain a key player in the industry, facilitating faster and more effective building practices.

Design Features

The 14 Hex Head Wood Screw is often made from high-quality steel, ensuring strength and resistance to wear The 14 Hex Head Wood Screw is often made from high-quality steel, ensuring strength and resistance to wear

The 14 Hex Head Wood Screw is often made from high-quality steel, ensuring strength and resistance to wear The 14 Hex Head Wood Screw is often made from high-quality steel, ensuring strength and resistance to wear 14 hex head wood screw. Some variants may be coated with zinc or other protective finishes to enhance corrosion resistance, making them suitable for outdoor applications or areas prone to moisture.

14 hex head wood screw. Some variants may be coated with zinc or other protective finishes to enhance corrosion resistance, making them suitable for outdoor applications or areas prone to moisture. 1. Construction Builders often use self-tapping bolts to fasten metal framing components or attach hardware in structural applications. Their ability to work without pre-drilled holes is a significant advantage in construction projects.

The A325 specification includes various criteria that these fasteners must meet, such as mechanical properties, dimensional tolerances, and testing procedures. One of the critical attributes of A325 bolts is their ability to withstand significant tension and shear forces, making them ideal for applications in bridges, buildings, and other infrastructure projects.

Shear studs are typically welded to the steel section of a composite beam before concrete is poured. Their primary function is to transmit shear forces between the steel and the concrete, preventing the two components from sliding apart under load. This connection enhances the load-carrying capacity of the beam and allows for a more efficient use of materials, ultimately leading to lighter and more cost-effective structures.

When installing rigid insulation nails, it is important to use the appropriate size and type of nail for the job. Using nails that are too short or too thin may not provide enough support for the insulation board, while using nails that are too long or thick may cause the insulation board to crack or buckle. It is also important to follow the manufacturer's recommendations for installation to ensure the nails are properly secured and the insulation board is adequately supported.

Key Benefits of Using Wedge Bolts

The M16 Foundation Bolt An Integral Component in Modern Firearm Design

They are widely used in metal-to-metal connections, wood-to-metal, or even in some plastic assemblies They are widely used in metal-to-metal connections, wood-to-metal, or even in some plastic assemblies

They are widely used in metal-to-metal connections, wood-to-metal, or even in some plastic assemblies They are widely used in metal-to-metal connections, wood-to-metal, or even in some plastic assemblies 3 8 self drilling screws. Their ability to drill and tap in one action saves time, effort, and often reduces the risk of misalignment that can occur with separate drilling and screwing steps.

3 8 self drilling screws. Their ability to drill and tap in one action saves time, effort, and often reduces the risk of misalignment that can occur with separate drilling and screwing steps. In addition to their ease of use and versatility, self-drilling anchor screws offer several other benefits. For one, they provide a flush finish, resulting in a clean and professional look. This makes them ideal for applications where aesthetics are important, such as in interior design projects. Self-drilling anchor screws also have a high load-bearing capacity, making them suitable for heavy-duty applications.

In automotive applications, these fasteners are employed in various assembly processes, from attaching body panels to securing engine components. Their chemical resistance ensures that they can withstand potential exposure to oils and coolant.

Hex drive timber screws are a robust, reliable, and versatile fastening solution for a myriad of woodworking and construction applications. Their design not only facilitates easy installation but also reduces common problems associated with traditional screws, such as stripping and corrosion. Whether you are a professional contractor or an enthusiastic DIYer, investing in quality hex drive timber screws can significantly enhance the durability and performance of your projects. As the demand for effective and efficient fastening solutions continues to rise, hex drive timber screws remain a top choice for those seeking strength and reliability in their work.

Selecting the Right Anchor Bolt

heavy duty tek screws. They can be driven into place using a variety of tools, including power drills and screwdrivers. However, it is important to note that these screws require a certain level of expertise to install correctly, as improper installation can lead to premature failure.

heavy duty tek screws. They can be driven into place using a variety of tools, including power drills and screwdrivers. However, it is important to note that these screws require a certain level of expertise to install correctly, as improper installation can lead to premature failure. 4. Simple Installation Installing M6% resin anchors is straightforward, requiring minimal tools. The process typically involves drilling a hole into the substrate, cleaning it to remove debris, inserting the anchor, and allowing the resin to cure. This efficiency in installation saves time and labor costs on the job site.

The design of tek screws is one of their most appealing aspects. Generally, they have a hex, torx, or slotted head, which facilitates easy application using power tools. The self-drilling tip is sharp, which allows it to penetrate materials without requiring an additional drill bit. Furthermore, the threading on a tek screw is optimized for a variety of materials, including metal, wood, and plastics, enabling it to secure different substrates firmly.

- Material Thickness It’s essential to consider the thickness of the material you are fastening. 16mm screws may not be suitable for very thick materials, so evaluating the thickness beforehand is crucial.