ceiling attic access door

Links

- The primary material used in cast iron panel casting is cast iron, which is a type of iron alloy containing carbon and silicon. The carbon content in cast iron can vary depending on the application, but it typically ranges from 2.5% to 4%. Silicon is also an important component in cast iron, as it helps to improve its fluidity and reduce its melting point.

- 4. Picture windows These windows are fixed in place and provide a clear view of the outdoors. They are typically larger than other window types and are often used as a focal point in a room.

- Another advantage of cast iron ornaments is their versatility. They can be used in a variety of settings, from traditional homes to contemporary spaces. Their classic design makes them a perfect fit for any decor style, from rustic to elegant. Whether you prefer a simple, minimalist look or a more ornate, detailed design, there is a cast iron ornament that will complement your home's aesthetic.

The ideal tolerance for aluminum profiles for windows and doors is what is outlined by BS EN 755-9:2001. However, most of the tolerances we offer to improve this particular standard.

Among the array of cast iron ornaments available, cast iron spear points stand out as striking focal points. With their intricate designs and sturdy construction, these cast iron spear points add both visual interest and a sense of security to any setting. Imagine a garden gate adorned with regal cast iron spear points, evoking a sense of grandeur and elegance that welcomes guests with timeless allure.

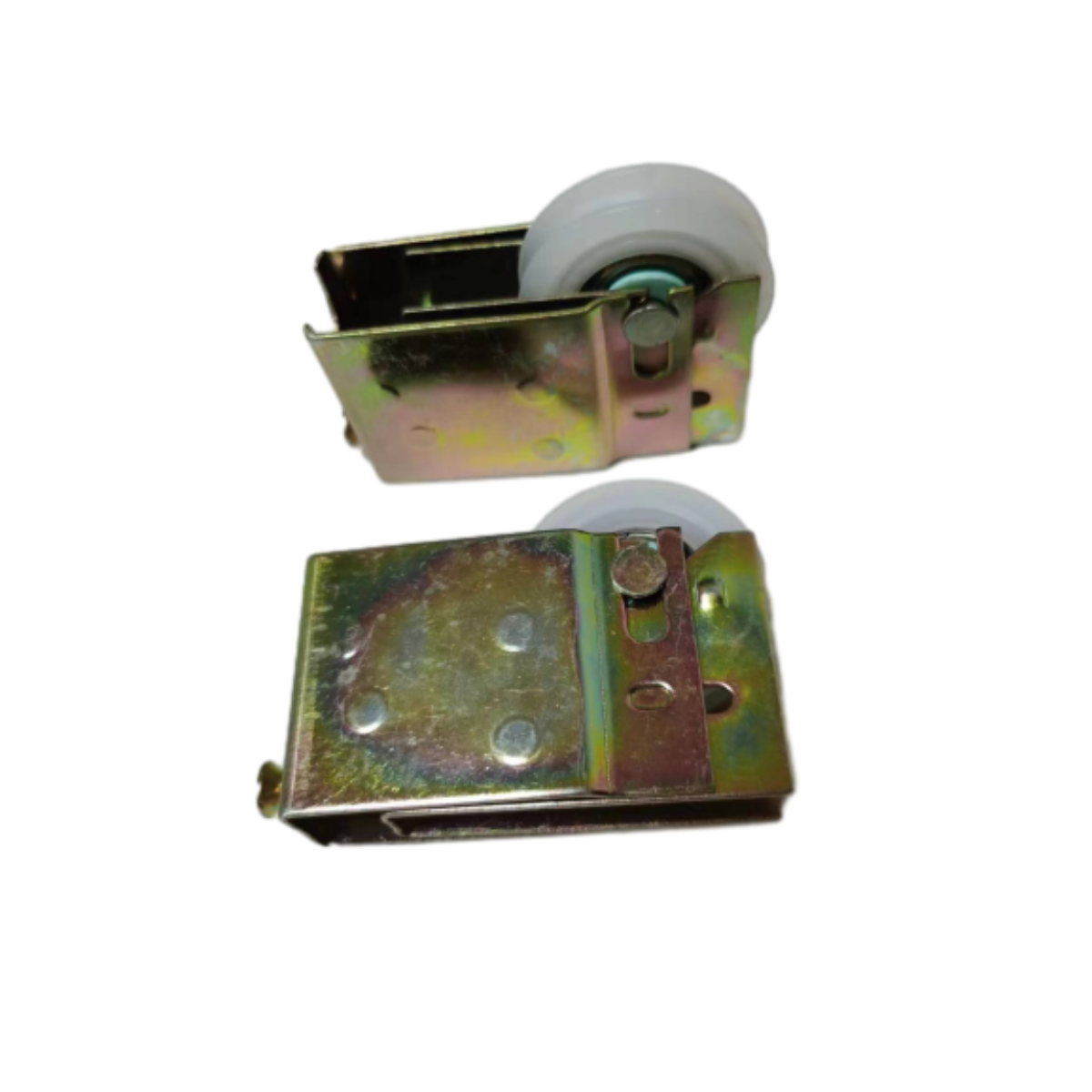

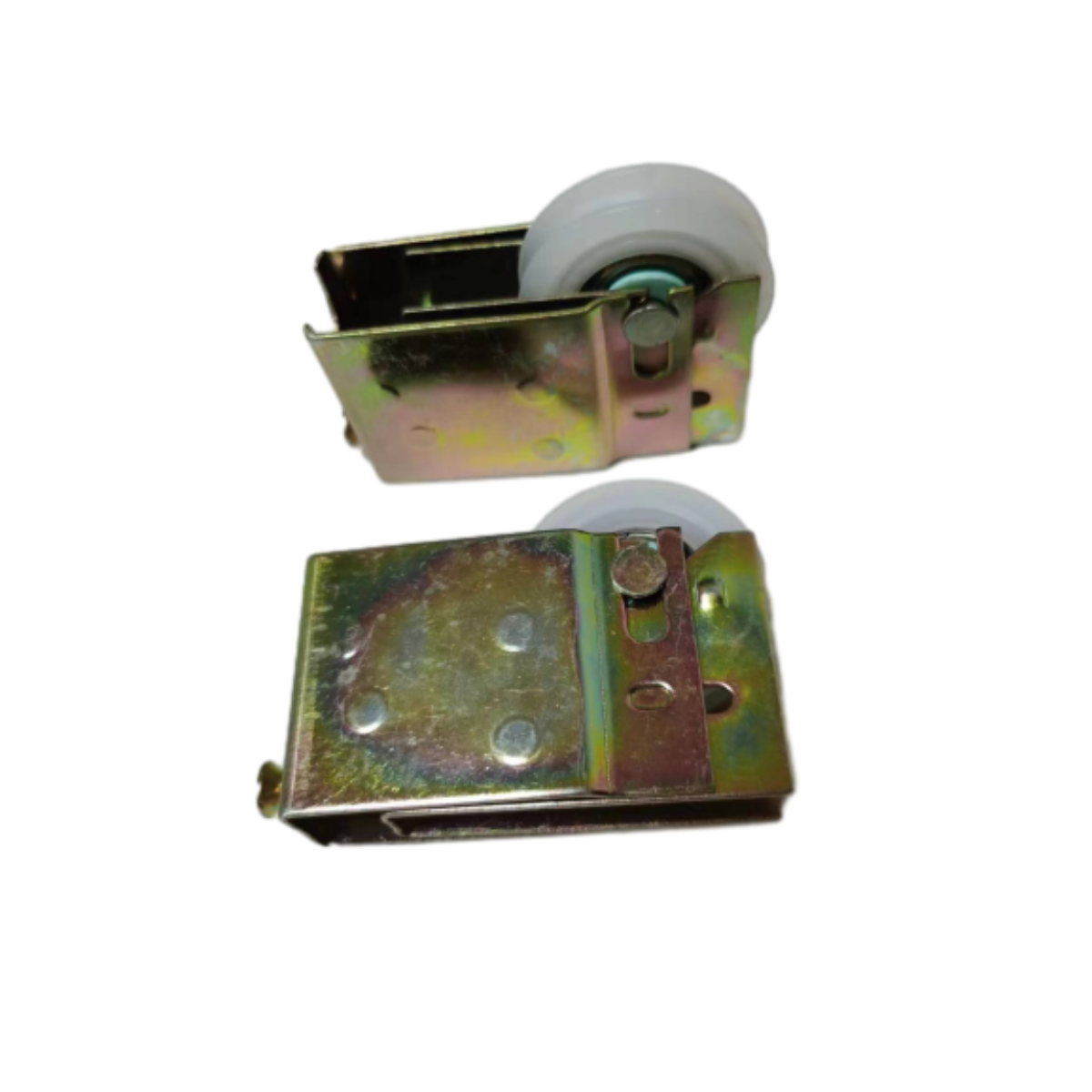

Its ability to handle dynamic loads with ease makes it a preferred choice in industries like manufacturing, automotive, and construction Its ability to handle dynamic loads with ease makes it a preferred choice in industries like manufacturing, automotive, and construction

Its ability to handle dynamic loads with ease makes it a preferred choice in industries like manufacturing, automotive, and construction Its ability to handle dynamic loads with ease makes it a preferred choice in industries like manufacturing, automotive, and construction sliding roller with steel housing.

sliding roller with steel housing. Glass

In conclusion, grey iron panel is a durable, versatile, cost-effective, and stylish option for a wide range of applications. Whether you are looking to enhance the security of your property, create an attractive boundary around your garden, or add a decorative feature to your outdoor space, grey iron panel is a reliable choice that can meet your needs. With its strength, resilience, customization options, and timeless appeal, grey iron panel is a popular and practical choice for both residential and commercial projects.

This is particularly beneficial in commercial settings where doors might be heavier or require more force to open This is particularly beneficial in commercial settings where doors might be heavier or require more force to open

This is particularly beneficial in commercial settings where doors might be heavier or require more force to open This is particularly beneficial in commercial settings where doors might be heavier or require more force to open 600mm pull handle. Moreover, the larger surface area can accommodate multiple fingers, providing better leverage and control.

600mm pull handle. Moreover, the larger surface area can accommodate multiple fingers, providing better leverage and control.  pull handle 600mm. This article aims to provide a comprehensive analysis of the 600mm pull handle, exploring its history, design, materials, and applications.

pull handle 600mm. This article aims to provide a comprehensive analysis of the 600mm pull handle, exploring its history, design, materials, and applications. But there are a few different types to choose from. So, if you’re weighing the pros and cons of each, explore wrought iron vs. aluminum and steel, and get the most out of your fencing upgrade.

They are used for structural purposes in different construction, architectural and industrial settings.

The most common component of contemporary wrought iron fences is the tubing made of iron or steel. The tubes are worked into forms by machines, and the manufacturers also utilize devices to produce the decoration traditionally used with a wrought iron fence. The lines are welded together to form wall panels, resulting in a robust iron fence.

Ensure that the chose aluminum profile meets the design specifications, including the required quality, structural, aesthetics, finish and compatibility with other building materials.

The rust-resistant properties of the material further add to their longevity, making them a wise investment for both residential and commercial properties The rust-resistant properties of the material further add to their longevity, making them a wise investment for both residential and commercial properties

The rust-resistant properties of the material further add to their longevity, making them a wise investment for both residential and commercial properties The rust-resistant properties of the material further add to their longevity, making them a wise investment for both residential and commercial properties cast iron gate ornaments.

cast iron gate ornaments. With pickets spaced about 4 inches apart along the fence panel, welds affix each one to both the top and bottom railings, keeping everything sturdy and completing the unit. A standard panel usually contains about 20 pickets apiece for an overall length of 8 feet. The full height of a finished iron safety fence panel mostly tops out at 5 feet, though 4-foot panels aren’t uncommon either. Local building codes tend to dictate the height required, so your experience may vary. Finally, at either end of a fence panel is a post.

Additionally, powder coated aluminum profiles for windows and doors can withstand corrosion and other harsh environmental conditions.

cast iron fence panels. While they may require an occasional cleaning to remove dirt and debris, they do not require regular painting or refinishing like other materials such as wood or vinyl. This means that you can enjoy the beauty of your cast iron fence panels without the hassle of ongoing maintenance.

cast iron fence panels. While they may require an occasional cleaning to remove dirt and debris, they do not require regular painting or refinishing like other materials such as wood or vinyl. This means that you can enjoy the beauty of your cast iron fence panels without the hassle of ongoing maintenance. Not only does this make the fence seem more excellent as a whole, but it also contributes to the general longevity of the fence once it has been built.