Despite the clear benefits of proper dustbin use, many people continue to dispose of their waste haphazardly. This challenges the effectiveness of waste management systems and underscores the need for ongoing public education. Governments and organizations should invest in ensuring that adequate dustbins are available in all public spaces, making it easier for people to comply with waste segregation practices.

The mechanism of a wedge type gate valve is relatively straightforward. When the valve is in the closed position, the wedge-shaped disc makes contact with the seats, creating a reliable seal that prevents fluid from flowing through. The angle of the wedge optimizes contact pressure, ensuring minimal leakage. As the handwheel is turned or the actuator is engaged, the stem moves up or down, causing the wedge to either lift or settle, thus controlling the valve’s open or closed status.

1. Ease of Installation One of the significant advantages of saddle clamps is their straightforward installation process. Most clamps can be installed without the need for specialized tools, which reduces labor costs and allows for speedy setup. This is particularly beneficial in agricultural settings where time is of the essence.

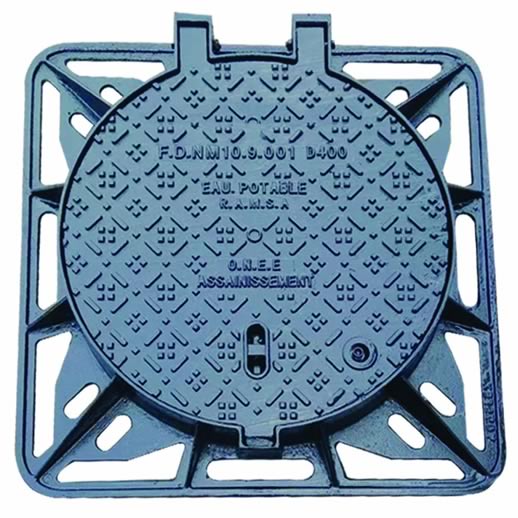

Why are manhole covers round?

What metal is used for manhole covers?

In modern urban environments, safety and aesthetics are paramount considerations for city planners and architects alike. Among the various street furniture options available, PAS 170 bollards have emerged as a significant resource in enhancing both protection and visual appeal. These bollards adhere to the Publicly Available Specification (PAS) 170 standards, ensuring that they meet rigorous safety and design requirements.

The 3% in 1 Dustbin Revolution A Call for Sustainable Waste Management

- Wastewater Treatment Plants Employed to help manage the flow of wastewater, facilitating treatment and discharge processes.

gate valve 1 1 2 inch

2. Size and Specification The dimensions of the gate valve play a pivotal role in determining its price. Larger valves require more material and are more complex to manufacture, leading to higher costs. Additionally, specific pressure ratings and customization for unique applications can also contribute to increased pricing.