t bar grid system

-

...

...

Links

1. Automotive Engines Timing belts are crucial in vehicles where they connect the crankshaft to the camshaft, ensuring smooth operation and performance.

ထို့ကြောင့် ဖလက်ဘုတ်စက်ပြားများကို ပြန်လည်အသုံးပြုခြင်း၏ အရေးပါမှုနှင့် လုပ်ငန်းဆောင်ရွက်လာသမျှကို အတိုင်းအဆင်မြင်အောင် သုံးသပ်ရမည်ဖြစ်သည်။

At its core, a belt is a flexible loop of material that transfers motion and power between two or more rotating shafts. In a pulley system, the belt connects the pulley wheels, allowing them to work in tandem. As one pulley rotates due to a power source, the belt transmits this motion to the other pulley, effectively transferring energy across the system.

4. Lightweight Design Belt drive systems tend to be lighter than chain systems, contributing to the overall performance and handling of the motorcycle. This aspect is particularly beneficial for manufacturers aiming to create lighter bikes without compromising durability.

1. Fuel Efficiency By efficiently transferring power and reducing drag on the engine, PK belts can contribute to improved fuel efficiency, a crucial factor in today’s energy-conscious world.

After confirming that everything is running smoothly, turn off the engine and give the belt one last inspection. Ensure everything looks correct and that the belt is seated properly.

- Alignment Misalignment can cause uneven wear and excessive noise, so it’s essential to maintain proper alignment between the belt and pulleys.

- Inspection Regularly inspect belts for signs of wear, cracking, or fraying. Addressing issues early can prevent failure and costly downtime.

1. Increased Efficiency These belts provide excellent power transfer, which can enhance the overall efficiency of the equipment they are used in.

Moreover, some PJ Belts are made from sustainable materials, reflecting a growing trend in the fashion industry towards greater eco-consciousness. This aligns perfectly with the values of today’s consumers, who are increasingly seeking products that have minimal environmental impact.

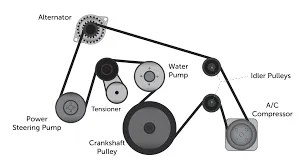

The timing belt serves a pivotal role within the engine. Its primary function is to keep the engine’s moving parts in sync. In a typical four-stroke engine, the crankshaft spins, driving the pistons up and down. Simultaneously, the camshaft must rotate in sync to open and close the valves at the right moment. The timing belt ensures that these operations do not occur out of sync, which could lead to engine damage.

The fan belt works through a system of pulleys connected to the engine. As the engine turns, it rotates the crankshaft, which, in turn, drives the fan belt around the designated pulleys. This motion generates the necessary force to power various accessories and systems in the vehicle. In essence, without a properly functioning fan belt, critical systems like the cooling system or electrical charging can fail, leading to overheating or battery drainage.

Timing Belt Replacement for Toyota Camry A Comprehensive Guide

Safety should always be a priority when it comes to driving. Many accessories can enhance the safety features of your car. For starters, a quality dash cam can provide invaluable evidence in case of an accident, capturing everything on the road. Furthermore, a blind spot mirror can help mitigate the dangers of switching lanes by providing a wider field of vision.

Importance of Engine Belts

3. Labor Costs The cost of labor can also affect the overall expense of replacing an alternator belt. If you opt to have the repair done at a dealership or specialized auto shop, you may pay a premium for labor compared to a local mechanic. The complexity of your vehicle’s design can also affect labor time and cost.

One of the most notable features of J section Poly V belts is their flexibility. The multiple ribs allow the belt to bend around small diameter pulleys, which is critical in many automotive applications where space is at a premium. This flexibility also helps to minimize vibration and noise, leading to a smoother operation and increased lifespan for both the belt and the components it interacts with.

Moreover, the COVID-19 pandemic highlighted the vulnerabilities of global supply chains, leading to a resurgence of interest in domestic manufacturing. As businesses reevaluate their supply chain strategies, there is an increasing push to bring production back to the United States. This trend has been referred to as reshoring, and it presents a significant opportunity for the manufacturing belt to reclaim its status as a vital player in the global economy.

1. Enhanced Durability High-quality ribbed belts are resistant to wear and tear, significantly reducing the frequency of replacements. This not only saves money but also ensures that your vehicle remains reliable over time.

In summary, understanding the role of the chain timing belt is crucial for any car owner. It offers unmatched durability and maintenance ease, often translating to better performance, especially in high-performance or heavy-duty applications. As technology advances, more vehicles are adopting chain timing belts, making them a key consideration for any future car buyer. Regular maintenance and proper installation can lead to a longer lifespan for these components, ensuring your engine runs smoothly for thousands of miles. Thus, whether you drive a performance vehicle or a standard sedan, knowing about your timing system is integral to maintaining the health of your engine and getting the most out of your vehicle’s performance.

Craftsmanship and Materials

To maximize the lifespan and performance of steel cord conveyor belts, proper maintenance is crucial. Regular inspections are necessary to check for signs of wear, damage, or misalignment. Cleaning the belts to remove dirt and debris will help maintain their functionality and prevent potential issues. Additionally, adjusting tension and tracking is essential to ensure that the belt operates smoothly and reduces the risk of slippage or breakage.

2. Chemical Resistance

The significance of ribbed belts in modern machinery cannot be overstated. Their efficient design allows for a compact arrangement of multiple components, saving space and weight in vehicles and equipment. This efficiency translates to improved fuel economy in cars and reduced energy consumption in industrial settings, contributing to overall cost savings.

What is a Timing Belt?

Washing machines are essential appliances in modern households, simplifying the daunting task of laundry. Among the many components that contribute to their functionality, the V-belt plays a crucial role in the operation of these machines. In this article, we will delve into what V-belts are, their significance in washing machines, common issues that arise, and tips on maintenance and replacement.

A timing belt is a looped belt made of reinforced rubber or urethane with teeth that mesh perfectly with the teeth on the gears of the pulleys. The primary function of the timing belt is to synchronize the rotation of the crankshaft and camshaft in an internal combustion engine, ensuring that the engine's valves open and close in time with the movement of the pistons. This synchronization is critical for optimal engine performance and efficiency, preventing any potential interference that could lead to engine damage.

What is a Fan Belt?

- Power Steering Loss A worn-out belt can impact the power steering system, making it difficult to turn the steering wheel.

Quality and Innovation

The Role of Belt Manufacturers

Unveiling the 1200-H8M-PK A Breakthrough in Smart Home Technology

1. الصوت العالي إذا سمعت أصوات صرير أو طقطقة، فقد يكون الحزام مشدودًا بشكل مفرط أو تالفًا.

In the intricate world of machinery and equipment, the role of v-belts cannot be overstated. As vital components in power transmission systems, v-belts are crucial for ensuring that machines operate efficiently and reliably. Consequently, the presence of quality v-belt suppliers is essential for industries ranging from automotive to manufacturing, agriculture, and beyond.

A timing belt is a crucial part of an engine's timing mechanism. It synchronizes the rotation of the crankshaft and the camshaft, allowing the engine's valves to open and close at the right time during each cylinder's intake and exhaust strokes. This synchronization is vital for optimal engine performance and efficiency. The timing belt is typically made from durable rubber with high-strength fibers, which enable it to endure the demands of engine operation.

In addition to power transmission, flat belts are also vital in a range of applications, including automation systems and material handling. For instance, conveyor belts used in assembly lines often utilize flat belts to transport products efficiently from one station to another. Their flat surfaces provide a stable platform for goods, reducing the likelihood of slippage or falling during transit. This is especially important in industries like food processing and packaging, where safety and hygiene are paramount.

Maintaining a Fiat Uno involves understanding the essential auto parts that enable the vehicle’s performance and safety. Whether opting for OEM parts from dealerships or exploring aftermarket options, it’s important to prioritize quality. With the right care and maintenance, the Fiat Uno can continue to serve as a reliable and economical mode of transportation for years to come. By being informed and proactive in sourcing parts, owners can ensure that their Fiat Uno remains in top-notch condition.

The timing belt set is a crucial part of any internal combustion engine, serving to synchronize the many moving parts that are essential for efficient operation. Proper maintenance and timely replacements can save vehicle owners from costly repairs and unwanted breakdowns. By staying informed about your timing belt set, you’re ensuring the longevity and performance of your engine. Always consult with a qualified mechanic if you suspect any issues, and adhere to your vehicle’s maintenance schedule to keep your engine running at its best.

4. Compact Design The design of timing pulley and belt systems allows for a more compact arrangement compared to other power transmission methods. This is particularly useful in applications where space constraints are a concern.

Conclusion

V-belts have a distinctive trapezoidal cross-section that enables them to fit snugly into the grooves of pulleys. This design allows for efficient power transfer and minimizes the risk of slipping. Typically made from durable materials such as rubber, polyester, and fiberglass, V-belts can withstand a wide range of temperatures, loads, and stretching. The layered construction of a V-belt often includes a tensile cord to enhance its strength and resistance to wear, ensuring longevity in challenging conditions.

Poly V-belts are a remarkable innovation in the world of power transmission, offering numerous advantages over traditional belts. Their efficiency, compact design, and durability make them an indispensable component in various industries. As technology continues to advance, we can expect to see further enhancements in poly V-belt design and materials, expanding their applications and improving their performance even further. Understanding the significance of poly V-belts is crucial for engineers, mechanics, and manufacturers aiming to optimize their machinery and vehicles for better performance and longevity.

Key Characteristics of Poly-V TB2 Belts

What is a PU V Belt?

PK belts are often used in applications where precise motion control is required, such as in conveyors, textile machinery, and agricultural equipment. Their robust design makes them suitable for high-load and high-speed applications, where reliability is paramount.

Understanding the Importance of Fan Belts in Automotive Systems