laminated ceiling tiles

...

...

Links

Серпантинный ремень играет безусловно важную роль в функционировании автомобиля. Без него многие системы просто не смогли бы работать. Например, отсутствие нормального охлаждения двигателя из-за неисправного компрессора может привести к перегреву автомобиля, что в свою очередь скажется на его производительности и долговечности.

Air conditioning systems are essential components in modern vehicles, ensuring comfort during often extreme weather conditions. One critical component that plays a vital role in the functioning of these systems is the V belt, particularly the PU (Polyurethane) V belt. While many may overlook the importance of this component, understanding its functions, applications, and benefits can highlight its significance in air conditioning systems.

While multi-speed belts offer numerous advantages, they also come with challenges. The complexity of their design can lead to higher manufacturing costs compared to standard belts. Additionally, precise alignment and tensioning are critical to ensure optimal performance, which may require specialized skills and equipment.

A V-belt is a type of Flexible Power Transmission Belt, characterized by its trapezoidal cross-section. This specific shape allows the belt to fit snugly into the grooves of a pulley, leading to enhanced friction and increased power transmission capabilities. V-belts come in various sizes and materials, including rubber and synthetic compounds, allowing them to handle different loads and environments. They are typically used in applications requiring a compact design and effective energy transfer.

Conclusion

Types of Power Transmission Belts

1. Enhanced Performance The 5% ribbed design improves the belt's grip on the pulleys, leading to more efficient energy transfer from the engine to various components. This increased efficiency can result in better overall engine performance.

The timing belt size 535-5M-15 is a vital component in various mechanical systems, providing reliable performance and precision. By understanding its characteristics, applications, advantages, and maintenance needs, users can make informed decisions that enhance efficiency and prolong the lifespan of their machinery. Whether in automotive applications or industrial uses, this timing belt remains an indispensable feature in modern technology.

The designation 7PK refers to a specific type of multi-ribbed belt characterized by its construction and dimensions. The 7 in 7PK indicates that the belt has seven ribs, while PK is a standardized code that signifies the belt's profile and design. Multi-ribbed belts, like the 7PK, are commonly used in automotive applications, particularly to drive components such as alternators, power steering pumps, and air conditioning compressors.

4. Engine Design Flexibility Non-interference engines often provide engineers with more freedom in designing other aspects of the engine. The additional clearance can lead to optimized designs for performance or fuel economy without the constraints of ensuring clearance between moving parts.

Tayland V-çənnə istehsalında yalnız məhsulun keyfiyyətinə deyil, eyni zamanda ekoloji cəhətlərə də diqqət yetirir. Bir çox istehsal müəssisələri, istehsal proseslərində ətraf mühitin qorunmasına yönəlmiş strategiyalar həyata keçirir. Bu yanaşma, yalnız əsas məhsulun keyfiyyətini artırmır, eyni zamanda cəmiyyət və gələcək nəsillər üçün də daha yaşıl bir dünya yaradır.

V-Belts and Flat Belts A Comparative Overview

Applications of Small Toothed Drive Belts

Belt maintenance is crucial for the optimal performance of rubber washing machines. Regular inspections to check for wear, tears, or misalignment can prevent potential failures and downtime. It’s advisable to replace belts at recommended intervals or when signs of damage are present. Neglecting belt maintenance can not only affect the cleaning efficiency but also lead to more significant mechanical problems in the washing machine.

Car seat belts are one of the simplest yet most critical safety features in vehicles today. Despite their undeniable importance, many drivers and passengers still neglect to buckle up, often underestimating the potential risks associated with not using seat belts. In this article, we will explore the history of seat belts, their mechanics, and why they are vital for road safety.

- Industrial Machinery These belts are increasingly used in conveyor systems, manufacturing equipment, and material handling apparatus, where reliable power transmission is crucial.

When it comes to replacement, it’s essential to use the correct size and type of V belt specified by the mower's manufacturer. Installing the wrong belt can lead to functional issues and potentially damage the mower.

Што тычыцца матэрыялаў, то варта ведаць, што не ўсе танныя рамяні робяцца з нізкакласных матэрыялаў. Напрыклад, шына гібрыдных матэрыялаў, якія спалучаюць тканіны і сінтэтычныя валакна, забяспечваюць добрую трываласць і зручнасць. Такія рамяні прыемныя на дотык і зручныя для насення на працягу доўгага часу.

The design of flat transmission belts is relatively straightforward. Typically made from durable materials such as rubber, fabric, leather, or synthetic compounds, these belts are crafted to withstand significant tension and demanding operational environments. Their flat design allows for a larger surface contact area with pulleys, enabling efficient power transmission without slipping.

2. Quality without Compromise Many manufacturers and suppliers willing to offer discounts are often doing so to clear inventory or promote a new line. Therefore, customers can find excellent quality products at a fraction of the original price.

Engine and Transmission Components

The temperature range directly impacts the longevity of your motor belts. Belts operating outside their optimal range are more prone to stretching, cracking, or glazing, which can lead to premature failure. By investing in belts with advanced thermal resistance, you save money on repairs and minimize downtime.

In the realm of automotive engineering, one cannot overlook the pivotal role that V-belts play in ensuring the smooth operation of vehicles. Originating from simple beginnings, these components have evolved significantly, particularly within the context of Japan's automotive industry. The significance of V-belts, especially in Japanese cars, extends beyond mere functionality; they symbolize precision engineering, reliability, and the meticulous approach that characterizes Japanese automotive manufacturing.

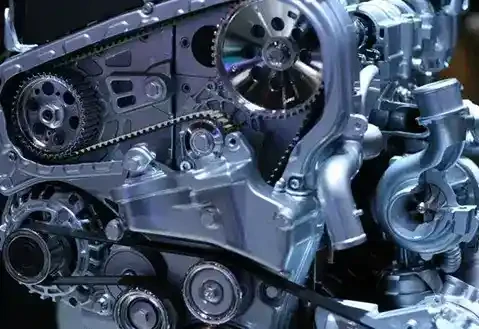

A V-ribbed belt pulley, often referred to as a serpentine belt system, consists of a pulley designed to work in conjunction with a V-ribbed belt. The belt is characterized by multiple ribs that run longitudinally, allowing it to grip onto the pulleys more effectively than traditional flat belts. The design provides enhanced power transmission capabilities and reduces slippage, making it an ideal solution for high torque and high-speed applications.

Understanding Motorcycle Chain Belts A Comprehensive Guide

4. Efficiency With multiple ribs making contact with pulleys, these belts offer superior grip and less slippage, enhancing overall efficiency in power transmission.

Advantages of Synchronous Belts

Performance and Efficiency

1. Improved Efficiency With a single belt driving multiple components, heavy duty serpentine belts promote smoother engine operation, aiding in fuel efficiency. This is crucial for heavy machinery that operates under high load conditions.

The B60 V-belt measures 60 inches in length, and its dimensions are designed to fit specifically into systems that require precise and reliable power transmission. The “B” designation indicates its width, which is approximately 1 inch, making it suitable for moderate power requirements. The B60 is built to withstand the stresses of various operating conditions, ensuring that it can efficiently transfer power with minimal slippage and wear.

Advantages of Variable Drive Belts

Construction of Poly V Belts

Understanding Poly-V TB2 Belts The Essential Choice for Modern Machinery

En anden bemærkelsesværdig aspekt ved 6PK1138 er dens evne til at lære og tilpasse sig brugernes præferencer. Gennem maskinlæring kan systemet analysere brugerens adfærd og justere indstillingerne for at tilbyde en skræddersyet oplevelse. For eksempel kan 6PK1138 lære, hvornår du typisk tænder lyset, og automatisk justere det til din foretrukne lysstyrke og farvetemperatur. Dette niveau af tilpasning skaber ikke blot komfort, men også en følelse af personlig forbindelse til teknologien.

Additionally, they are common in woodworking and metalworking equipment, where precision and reliability are critical. As industries evolve, so does the demand for efficient power transmission systems, placing the A Toothed Flat Belt Drive at the forefront of modern engineering solutions.

To maximize the lifespan and performance of small toothed belts, regular maintenance is essential. Here are some tips

To ensure optimal performance, proper installation and maintenance of the 135J6 poly V belt are crucial

Toothed conveyor belts play an integral role in modern industrial operations. Their unique design, coupled with the benefits they offer, makes them indispensable in various sectors, including manufacturing, food processing, automotive, textile, and packaging industries. As technology continues to evolve, the development of advanced toothed conveyor belts will likely yield even greater efficiencies and innovations, paving the way for more streamlined operations. Understanding the functionality and advantages of toothed conveyor belts is crucial for industries seeking to optimize their production processes and enhance overall productivity.

The Role of Belts in Cummins Engines

3. Proper Alignment Ensure that the timing belts are properly aligned. Misalignment can lead to slippage and decreased print quality. Adjust the tension and alignment according to the manufacturer's specifications.

Moreover, conveyor belts are increasingly utilized in recycling facilities, helping to sort and process waste materials more effectively. The versatility of conveyor systems makes them indispensable in modern industrial operations, proving that their utility extends far beyond mere transportation.

2. Product Specifications Ensure that the wholesale fan belts meet the specifications required for the intended application. This includes checking the size, material, and compatibility with existing systems.

In manufacturing and material handling, variable belt drives are employed in conveyors, mixers, and machining equipment. Their ability to adapt to changes in load and speed requirements means that production processes can be more efficient, reducing energy consumption and minimizing wear on equipment.

Replacing the timing belt on your Toyota Camry is a complex task that generally requires professional assistance. However, understanding the basic steps can give you a better idea of what to expect

1. Tension Checking Inspect the belt tension regularly. Too much or too little tension can lead to decreased efficiency and premature wear.

Maintenance Tips for Timing Belts