cheap pvc ceiling panels

-

...

...

Links

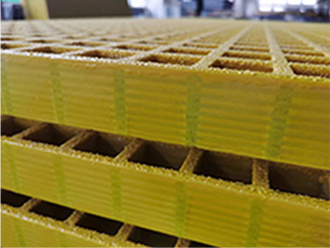

The versatility of fiberglass floor grating makes it suitable for a wide range of applications. It is used extensively in industries such as chemical processing, food and beverage, wastewater treatment, and marine environments. Additionally, fiberglass floor grating can be found in recreational facilities, parking garages, walkways, and platforms. Its ability to be molded into various shapes and sizes allows it to meet specific design requirements, accommodating custom installations and varied load capacities.

The manufacturing process of molded FRP can vary depending on the desired characteristics of the final product. Common methods include hand lay-up, spray-up, and compression molding. Each technique offers distinct advantages, such as improved finish quality, reduced labor costs, and enhanced production efficiency. For instance, the hand lay-up method allows for greater control over the fiber orientation and the quality of the fiber-resin bond, making it suitable for high-performance applications. On the other hand, compression molding is excellent for producing large quantities of consistent parts in a shorter time frame.

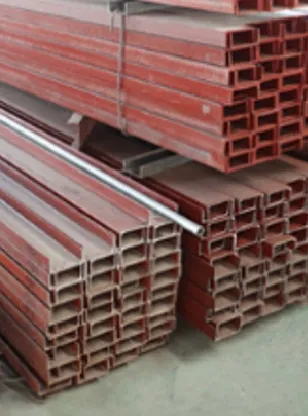

Considerations When Choosing CHS Tube Sizes

4. Eco-Friendly With the rising focus on sustainable construction practices, FRP sheet piling offers an environmentally friendly alternative. Many FRP materials are recyclable, and their long service life reduces the need for frequent replacements, leading to lower environmental impact over time.

Understanding FRP Stairs A Modern Solution for Structural Needs

5. Versatility FRP rebar can be manufactured in various diameters and shapes, making it suitable for a range of construction projects, whether they are beams, slabs, or specialized architectural features.

- Residential Areas For domestic water supply needs, ensuring a hygienic and reliable water source.

One of the most prominent applications of FRP vessels is in the chemical and petrochemical industries. Due to their exceptional corrosion resistance, FRP vessels are ideal for storing aggressive chemicals and harsh solvents. Unlike conventional materials, FRP does not rust, which minimizes leakage risk and enhances safety.

The versatility of FRP grating means it is utilized across a broad spectrum of industries. In the construction industry, it is frequently employed as walkways, stair treads, and industrial flooring, providing a safe and durable surface for workers. In the marine sector, FRP grating is used on docks, piers, and boat decks, where its resistance to saltwater and UV radiation is invaluable.

3. Customization and Features Custom-built vessels tailored to specific requirements often come at a premium. Whether it’s modifications for unique operational needs or enhanced features such as additional safety measures or specialized coatings, customization plays a crucial role in determining the final price.

What is GRP Grating?

3. Non-Conductive Properties Unlike metal posts, fiberglass rods do not conduct electricity. This property is particularly important in electric fence systems. It helps to minimize the risk of accidental electric shocks during installation and maintenance while ensuring that the fence operates efficiently without energy loss through the support posts.

Fiber Reinforced Polymer is a composite material made of a polymer matrix reinforced with fibers, such as glass, carbon, or aramid. The unique combination of these materials offers exceptional strength-to-weight ratios and resistance to various environmental factors, which is particularly important for applications exposed to harsh conditions.

Investing in FRP grating comes with numerous advantages, justifying its cost

While galvanized stock tanks offer numerous advantages, there are several factors to consider before making a purchase

Another noteworthy advantage of FRP decking is its superior safety features. The surface of FRP grates can be manufactured with anti-slip textures, providing increased traction even in wet conditions. This is particularly significant in industrial settings where workers need to navigate potentially hazardous surfaces. Furthermore, the lightweight nature of FRP means that installation is typically easier and faster than for heavier alternatives, reducing labor costs and time delays on construction projects.

2. Agriculture

There are several types of water softener systems available in the market today

In various regions, especially in Europe, CHS tubes are often categorized according to national or international standards, which specify the dimensions and mechanical properties. The most widely recognized specifications include those set by the European Committee for Standardization (CEN), the American Society for Testing and Materials (ASTM), and the International Organization for Standardization (ISO). These standards ensure consistency and reliability across different manufacturers and regions.

Conclusion

Water is a vital resource for all living organisms, and its storage and management are crucial for various applications, ranging from residential use to agricultural irrigation and industrial processes. One effective and widely adopted form of water storage is the galvanized water storage tank. These tanks are engineered to offer durability, corrosion resistance, and efficiency in water management systems.

In the realm of industrial fluid storage, the 1054 FRP (Fiber Reinforced Plastic) vessel stands out as a paragon of modern engineering and material science. As industries increasingly demand robust, reliable, and long-lasting storage solutions, the 1054 FRP vessel offers an exemplary balance of these attributes.

The aesthetics and versatility of FRP mesh grating also make it an appealing option for architects and designers. Available in various colors, patterns, and sizes, FRP grating can be customized to blend seamlessly into the surrounding environment or to fulfill specific design visions. This flexibility allows for the creation of visually appealing structures without sacrificing functionality. Whether it’s used in parks, walkways, or entertainment venues, FRP grating can enhance the appearance of a space while providing necessary load-bearing capabilities.

The installation process for GRP insulated water tanks is relatively straightforward compared to their steel or concrete counterparts. Their lightweight nature allows for easier transportation and quicker assembly, which can be particularly advantageous in urban settings where space may be limited.

Durability and Maintenance

1. Corrosion Resistance One of the most significant advantages of FRP materials is their resistance to corrosion. Unlike traditional metal rods, which can rust and degrade over time when exposed to moisture and chemicals, FRP rods maintain their integrity. This feature is particularly beneficial in water treatment plants or industrial applications where corrosive substances are prevalent.

Cost-Effectiveness

Conclusion

What is GRP Grating?

5. Custom Features Many buyers seek custom features for their vessels tailored to their specific needs. Options such as additional reinforcements, specialized coatings, or integrated technology can add to the complexity and price of the vessel. Custom-built solutions cater directly to client specifications and can therefore justify a higher pricing structure.

Conclusion

Fiberglass fence rods are composite materials made from glass fibers and polymer resins. This combination results in a strong yet lightweight material that is resistant to corrosion, rot, and UV degradation. Fiberglass rods are typically available in various lengths and thicknesses, allowing for customization based on the specific requirements of a fencing project.

1. Industrial Supply Companies Many industrial suppliers offer a wide range of galvanized tanks suitable for various applications. These companies often provide expert advice and guidance to help you choose the right tank for your needs.

As industries become more environmentally conscious, fiberglass rod manufacturers are responding by innovating new materials and production processes. Many are exploring the use of recycled materials in their composite formulations, reducing waste and the environmental impact of production. Furthermore, advancements in manufacturing technologies allow for more precise and efficient production, minimizing energy usage and enhancing sustainability.

In conclusion, FRP grating walkways represent a significant advancement in materials science, bringing a host of benefits that traditional materials struggle to match. Their corrosion resistance, high strength-to-weight ratio, safety features, low maintenance requirements, and environmental sustainability make them an ideal choice for various applications. As industries continue to prioritize longevity, safety, and cost-efficiency, FRP grating walkways are set to play a vital role in the infrastructure of the future.

Durability and Maintenance

5. Regulatory Factors

One of the biggest concerns in both commercial and residential construction is the wear and tear of materials over time. Traditional stair treads made from wood, metal, or concrete can be susceptible to corrosion, rust, and decay. In contrast, Fibergrate stair treads are resistant to these issues thanks to their fiberglass composition. They do not rust, corrode, or warp, significantly reducing maintenance costs over time. This durability extends the lifespan of buildings, making these treads a cost-effective investment for long-term safety and functionality.

- Agriculture Farmers often use FRP tanks for irrigation, livestock watering, and rainwater harvesting, benefiting from the tanks’ lightweight and customizable features.

Properties and Benefits

In addition, chlorination is a widely used technique for ensuring the microbiological safety of well water. By adding a controlled amount of chlorine, harmful bacteria and pathogens can be effectively killed. However, it's crucial for homeowners to monitor chlorine levels and the byproducts formed, as excessive chlorination can lead to other health risks.

Water softener systems offer a range of benefits that improve the quality of water for household and industrial use. By understanding the implications of hard water and the advantages of installation, individuals can make informed decisions that enhance their living environments. The investment in a water softener not only leads to savings in appliance maintenance but also contributes to a healthier lifestyle through improved water quality.

5. Versatile Application Open steel floor grating can be utilized in a variety of settings, from industrial sites to commercial buildings. Its ability to support heavy machinery, employees, and equipment makes it an invaluable asset in numerous industries.

Environmental Benefits

Conclusion

Moreover, with growing concerns about environmental sustainability in the construction industry, Safe T Deck systems present a more eco-friendly option. Since the decking remains in place, there is less material wastage compared to traditional construction methods that require temporary formwork, which is often disposed of after a single use. Consequently, using Safe T Deck contributes to reducing the environmental footprint of building projects.

Fiberglass Reinforced Plastic Grating An Overview

Applications of FRP Water Storage Tanks

Environmentally Friendly

The importance of water vessel filters is underscored by the growing global water crisis. According to the United Nations, approximately 2 billion people worldwide lack access to safe drinking water, which can lead to severe health issues, including cholera and other waterborne diseases. Effective filtration technologies can help mitigate this problem by providing cleaner water, thus improving public health and reducing healthcare costs.