ceiling mineral fiber

-

...

...

...

Rigid mineral wool insulation board, also known as rock wool insulation, is an innovative and sustainable building material widely used in construction and insulation projects. Its unique properties make it an ideal choice for both residential and commercial applications. This article explores the characteristics, benefits, applications, and environmental impact of rigid mineral wool insulation boards.

Safety is a top priority in any construction project, and ceiling mineral fiber excels in this regard. Most mineral fiber products are classified as non-combustible, meaning they do not ignite easily and can resist fire spread. This fire-resistant characteristic helps to enhance the overall safety of a building, making it an ideal choice for public spaces and areas where fire safety regulations are stringent.

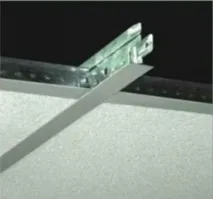

ceiling mineral fiber

An often-overlooked yet impactful benefit of suspended ceiling tile grids is their contribution to energy efficiency. By installing energy-efficient lighting panels alongside the tiles, businesses and homeowners can significantly reduce their energy consumption. With the added insulation from these ceilings, there can also be improvements in heating and cooling efficiency, contributing to lower utility bills over time.