gridstone ceiling tile

-

...

...

Links

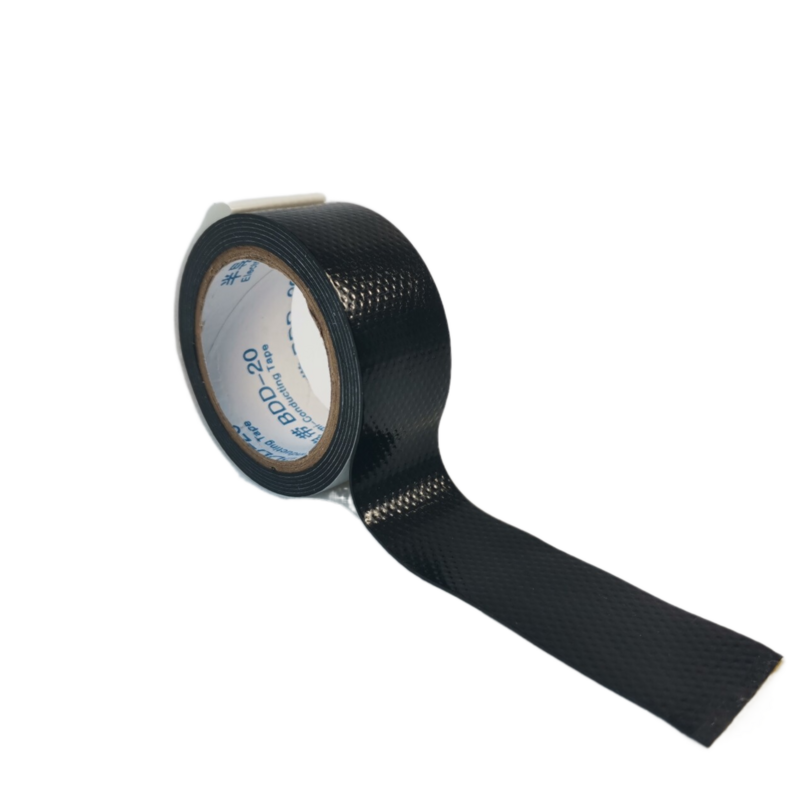

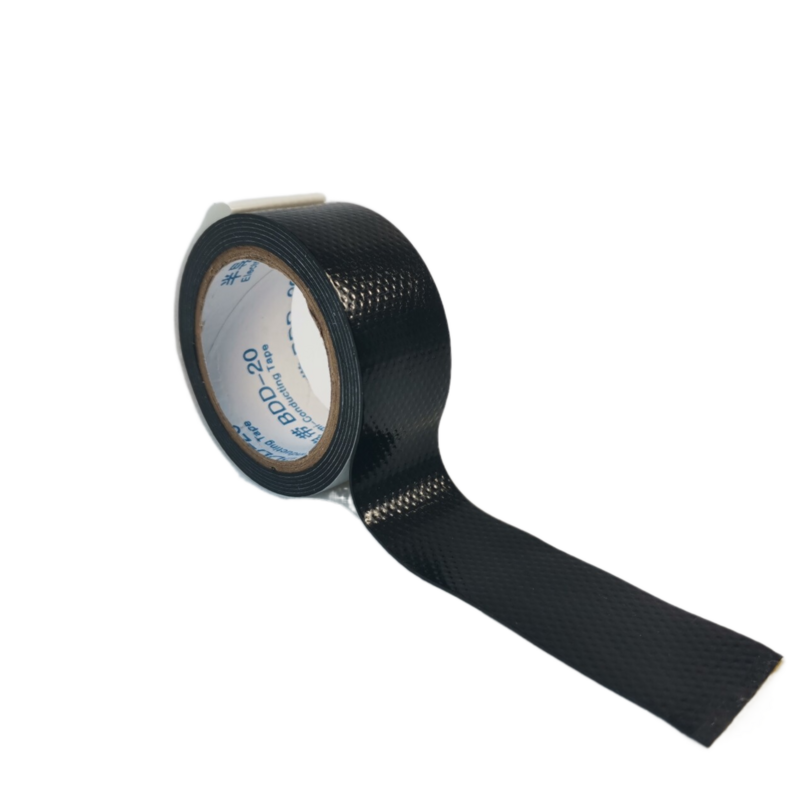

It has an abrasion-resistant backing that lasts long and has flexibility, which makes it a prime option for insulating electrical connections during electrical tapping.

In the construction business, there is always a need for versatile and reliable sealing materials. Butyl rubber sealant tape is a heavy-duty adhesive that provides exceptional flexibility, strength, and waterproofing capabilities. It is a powerful solution that is used to tackle various sealing and waterproofing applications, from sealing windows and RVs to patching rubber roofs on boats and repairing glass. In this article, we will explore the different facets of butyl rubber sealant, including its uses and installation.

Insulating tape is also used for color-coding electrical wires. In complex wiring systems, it can be difficult to trace which wire connects to which component. By using different colors of insulating tape to wrap around the wires, technicians can easily identify which wires belong to which circuits. This makes troubleshooting and maintenance much easier and more efficient.

4. Pricing and Distribution

3. Flexibility and Compressibility Butyl weather stripping is highly flexible, allowing it to conform to irregular surfaces and effectively fill gaps of varying sizes. It can compress under pressure yet return to its original shape, maintaining a consistent seal regardless of temperature changes.

The tape's adhesive strength and flexibility provide an extra layer of security, preventing unexpected breakages during intense matches The tape's adhesive strength and flexibility provide an extra layer of security, preventing unexpected breakages during intense matches

The tape's adhesive strength and flexibility provide an extra layer of security, preventing unexpected breakages during intense matches The tape's adhesive strength and flexibility provide an extra layer of security, preventing unexpected breakages during intense matches vulcanizing tape.

vulcanizing tape. (5) For occasions requiring complete flame retardant, flame retardant products are also available;

3M rubber tapes have operating temperatures ranging from 176°F (80°C) to 221°F (105°C). Some, like Scotch® Linerless Rubber Splicing Tape 130C and Rubber Splicing Tape 23, have overloads temperatures up to 266°F (130°C). Because of this high heat attribute; there are many industrial settings where it is common to use rubber tape in lower voltage applications to moisture seal, pad and insulate:

Most tapes come with an adhesive backing that adheres firmly to most surfaces, including concrete, wood, and vinyl Most tapes come with an adhesive backing that adheres firmly to most surfaces, including concrete, wood, and vinyl

Most tapes come with an adhesive backing that adheres firmly to most surfaces, including concrete, wood, and vinyl Most tapes come with an adhesive backing that adheres firmly to most surfaces, including concrete, wood, and vinyl yellow black tape for floor. To ensure a secure bond, it's important to clean the surface thoroughly before applying the tape. Once applied, the tape should be pressed down firmly to remove any air bubbles and ensure a smooth, even surface.

yellow black tape for floor. To ensure a secure bond, it's important to clean the surface thoroughly before applying the tape. Once applied, the tape should be pressed down firmly to remove any air bubbles and ensure a smooth, even surface. Adhesives are a sadly overlooked aspect of tape selection. When you're purchasing tape for your business, it's easy to think about things like the material and the number of rolls. But too often, people don't consider the importance of the tape's adhesion. Different varieties of tape use different types of adhesive with different properties. If you don't factor in the adhesive type when you choose your tape, you might end up with an adhesive that's too weak or too strong for your projects. Too weak, and the tape will come loose. Too strong, and the tape might rip off paint or damage cardboard.